|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

I would assume they were painted black along with the chassis.

Posted on: 2024/8/18 20:16

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

The fuel tank on my 53 Cavalier is black, looks all original to me.

Posted on: 2024/8/18 23:49

|

|||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

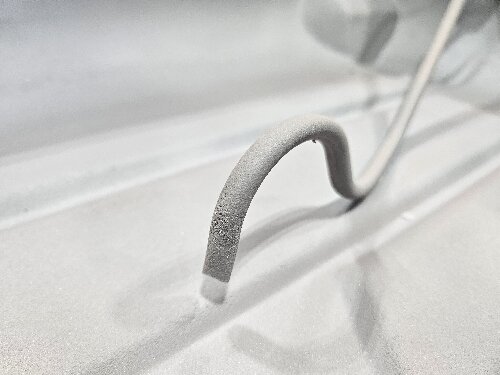

Coated the inside with Ospho, then will do the full treatment with Hirsch's sealer when I'm ready.

Finally getting to welding the two halves back together. Struggling with preventing the weld from blowing through the metal. I have it turned all the way down, and am doing very quick spot welds, alternating locations. Still can't seem to get it consistent. It's not a very good welder, and I'm not a good welder either.

Posted on: 2024/9/14 17:12

|

|||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Were the tanks originally painted black, or were they gray/silver, or bare stainless steel? These were originally painted back and definitely were not stainless! If they were, there would be no rust out. Quote: Coated the inside with Ospho, then will do the full treatment with Hirsch's sealer when I'm ready. This is exactly what I did on my 1951 Henney-Packard's tank which is much larger than the one shown here. It took several coats as it was so full of holes but no sign of leakage although it's not full either. Hirsch's sealer is the one I always use but for my tank their little one quart sealing kit fell far short of what it needed so I used it, then bought a gallon and used much of it too. I painted it using a Hirsch silver paint which is very, very hard, then roughened it up with sandpaper, then painted again with the chassis paint. Mine did not have undercoating which was a dealer added option.

Posted on: 2024/9/14 18:09

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

I have considered picking up the Arcaptain MIG200 for when I start doing some metal work on my car. Karl gives it high praises. He's got a good YouTube channel............a good Canadian boy! youtu.be/O_VNipL8bfY?si=0XbkxpIrwAIWQ2-F I'm not a good welder either, so I have to at least have a good machine so I have a fighting chance!

Posted on: 2024/9/15 9:06

|

|||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for the recommendation on that welder. Looks promising. If I try to save my parts car then I will pick up a welder and see what I can do

Did some research and realized that welding sheet metal is best with smaller wire and shielding gas. So I replaced what was in the welder (.035 flux core) with .023 wire and 75/25 shielding gas. Much better results, but I'm still getting random burn through. I have two sides almost done. Once I have it all done I'll grind down the welds and patch any pinholes. Lots of work!

Posted on: 2024/9/18 23:34

|

|||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

With that metal being 70 years old and rusty. Thin spots

May of been better to Weld a strip of new metal on the inside. Half and half. Then put other half piece on and Weld to that Stronger joint and some metal to Weld to.

Posted on: 2024/9/19 1:11

|

|||

|

Riki

|

||||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Webmaster

|

I commend your effort!

Even though I can weld addiquitely, not sure I would tackle welding an entire fuel tank. Welding two things together is for sure different than welding two things and having them be leak proof. If it were me, I'd find a local TIG welder that has experience welding tanks/vessels/etc. TIG may be a better process, especially with thin metal.

Posted on: 2024/9/19 7:08

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 51-56' fuel tank internals

|

||||

|---|---|---|---|---|

|

Home away from home

|

Riki - yes, that was something I considered. But I figured maybe I could bend the joints and overlap them some to have the same effect. Turns out that didn't work. I tried for quite a while but could never get the top to sit over the bottom all the way around. I gave up, bent the edges back to straight, and now am welding a butt-joint.

Kev - This is a bit of an experiment. I know Ross refurbed a tank like this, but he's a great welder and I'm not. If I can successfully do it then that's great. If not then nothing lost but some time and $100 for sandblasting. This tank was essentially trash anyways. I do still have the old from my brother-in-laws 200 that could be salvaged if I can get all the rust out of the inside. TIG welding would probably be much better, but I'd like to see if I can do it without paying anyone to do it for me. I'm hoping that between welding up all the holes, sealing the inside, and maybe running something like seam sealer on the outside will be enough to keep it leak free. Or maybe after I weld the two halves together I can go around the outside and braze or silver solder the joint. We'll see. Either way I'm getting lots of experience with a cheap welder. -Kevin

Posted on: 2024/9/19 11:04

|

|||

|

||||