|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just bumping this because it only had a very short life in the top ten and I think it important enough to get a bit more exposure.

Posted on: 2009/6/9 19:21

|

|||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Home away from home

|

Owen, my 47 Custom Clipper has developed a leak in the radiator. I plan on removing the fan and water pump to ease the job of getting the radiator and cradle out. While the pump is off I plan on removing the distribution tube and see what I see. You are right, this is an easily over looked maintenance task that can lead to a cracked block. I think too much of my 356 engine to have it destroyed by a bad tube. Thanks for sharing.

Posted on: 2009/6/10 9:47

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Home away from home

|

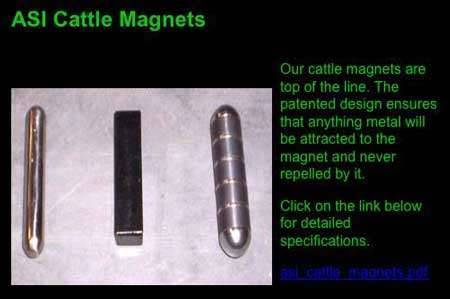

I used a magnet on a 3' piece of 1/2" electrical conduit. (The magnet is a cow magnet you give livestock to captcher bits of metal). I tied very strong string line to both the magnet and the conduit, and taped both very well with electrical tape. I inserted the magnet in the conduit and moved the whole works into the water jacket where the water distribution tube rests. The magnet fell off at the end (probably attracted to the far wall), and I drug the conduit and the magnet back towards the front. If you aren't 100% sure the magnet is well attached to the conduit, don't try this as it would be no joy to get that magnet out.

However, I was able to recover A LOT of small metal pieces, including a broken extractor and left over threads from a removed exhaust stud. The key was to drag the magnet over the bumpy bottom, where the cast iron cylinders create a bunch of peaks and valleys. Do it many times, you'll be surprised what you find. Of course this won't recover non-ferrous metals, such as brass or aluminum. It would have worked, I think, on your steel distribution tube, and may be worth the effort to grab that last few pieces. I removed three of the five frost plugs and flushed the jacket with over 15 gallons of water until it ran clear. I also used the conduit and a small shop vac, but didn't recover much except old anti-freeze. Attach file:  (14.77 KB) (14.77 KB)

Posted on: 2009/6/10 10:53

|

|||

|

-Carl | [url=https://packardinfo.

|

||||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thanks for the thoughts on the magnet, we did have one but it wasn't particularly strong.

Moving along on the job, all the valves but one are OEM Packard-logo Rich, the other being a Packard-logo Eaton. All the exhausts had been previously cut and will be replaced, not enough margin to reface again, and one exhaust had a crack in the face. All the intakes are fine, as are the seats, still nice and narrow too! I'll power-grind the seats with my Sioux refacer tools. One guide, same cylinder as with the cracked valve, had a guide which was cracked and mushroomed at the top, and badly worn to boot. It was easily removed with the K-D Packard valve guide drift, and we may change some others as well. Unlike some of the later engines, the intake and exhaust guides are different, and the style changed in mid-1938 to provide a relief at the top to minimize sticking. The two styles are set to different heights, well diagramed in the 1938 shop manual. Once you start, where do you stop? Decided to re-gasket the manifolds at the same time. May or may not need surface grinding, have yet to check. Such fun, even though it's not my own car. EDIT - should have noted it's a 90,000 mile car, at least it's second valve job, perhaps even the 3rd as intervals of 25,000 to 40,000 miles is pretty typical for these engines.

Posted on: 2009/6/10 11:55

|

|||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Are replacement tubes available or specs.?

Posted on: 2009/12/17 0:12

|

|||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Quite a regular

|

When one is removing the remanents of the water distribution tube, would it be advisable to replace the "freeze plugs" for better access for probing in the water jacket?

Same for the head? What did you replace the tube with? Lowell 39 S8

Posted on: 2009/12/18 0:25

|

|||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Though some Chrysler and other makers used steel water distribution tubes (probably galvanized), I believe the ones Packard used were always brass. So unless it was for some reason replaced with a steel (aftermarket, like Dorman) unit or otherwise damaged, they usually just require removal and cleaning, not replacement. Yes, replacements are available if you need one.

As to removing core plugs to help clean water jackets, sure if you've got an overheating condition, removing them to help clean and flush is a good idea.

Posted on: 2009/12/18 9:23

|

|||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Webmaster

|

If you look at my project blog you can see the tube I removed. They are all "basically" the same. As it's thin brass you just need to be gentle with it. Otherwise it would be ok to reuse unless someone damaged it previously.

Posted on: 2009/12/18 17:34

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: Water distribution tube

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'm of the opinion that if anyone wants to remake these they should make them out of stainless steel. Gauge for gauge, it would be stiffer and a heck of a lot more durable than the original brass.

Posted on: 2009/12/18 18:22

|

|||

|

||||