|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Probably others more versed in this for automotive but I would think something like a Time Serttimesert.com/ or E-Z Lockezlok.com/InsertsMetal/index.html repair would be a better alternative since they are solid units vs a coiled wire that just winds in. In medical equipt I've worked on, this solid type was factory supplied when a repair to a stressed piece was needed.

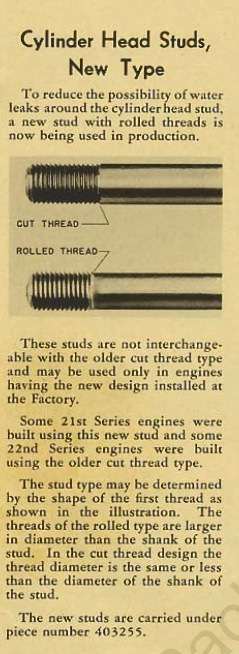

Since the 21st series, Packard studs have a special thread on the end into water jacket to reduce leaks. If you use the proper stud, that might be an issue threading into any kind of repair as apparently happened in reverse causing your original problem. Packard mentions they are not interchangeable so you may need to buy or have a special stud made for the repaired spot if your old one that was changed is not usable. Attach file:  (27.67 KB) (27.67 KB)

Posted on: 2010/10/18 9:21

|

|||

|

||||

|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Thanks HH56! will definitely check and see if I have the right threads! Have a great one. Ramon

Posted on: 2010/10/19 5:45

|

|||

|

||||

|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Home away from home

|

Regardless of the type of thread on the stud replaced or used it is most advisable to always use permatex on stud or head bolts that screw into the block or any other application where a water jacket is involved. The Permatex is required and common factory recommended practice for Chevy V8's since 55.

As for replacing the stud, if the threads in the block are bad then maybe go out to the next metric or standard US size that is the smallest. Need to find a replacement stud first to make that decision. Just drill and tap to the next closest size. The problem with heli coiling or other thread inserts in this particular case is the thin amount of material near a water jacket. Drilling and tapping to the next closest available size (metric or US or otherwise) most likely will remove the least amount of material from the block.

Posted on: 2010/10/19 8:15

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Home away from home

|

Some years back I had a '39 Cadillac 60 Special. I had to remove the heads to do a valve job. This engine uses bolts to fasten the cylinder heads to the engine block, and some, if not all screw into the water jacket. One of the bolt holes was damaged by rust. I used a Heli-Coil insert to repair the threads. As mentioned above, I also used a Permatex sealer on the threads of all the bolts going into water jackets to prevent leakage. Oh yes, I replaced all the bolts with new ones. Don't know if repairing for a bolt or a stud would be different, but this is my experience.

(o{I}o)

Posted on: 2010/10/19 10:22

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Many years ago I stripped a stud thead in a 1954 359 block because I didn't realize the aluminum head was thicker than the replacement cast iron 327 head. I had a friend who worked for United Engine Rebuilders and their advice was a device called a Tap-Lock as I remember. It required drilling out the damaged thread quite large, perhaps 5/8 or 3/4, tapping with an NPT pipe thread, screwing in the adapter, and finish filing flush with the block. Whether it was the best or correct solution, it was a permanent repair.

Posted on: 2010/10/19 10:33

|

|||

|

||||

|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have installed a 7/16-20 helicoil many times in Packard blocks with perfect success to date. I have even done it without removing the head as the hole through the head is a great oversize to guide the drill bit for a nice straight shot. Its a little painful to buy the Helicoil set to do one, but rather necessary. Helicoils were good enough for instruments undergoing the rigors of launch on the spaceshuttle--they are good enough for me. But do use some sealer!

Posted on: 2010/10/19 11:06

|

|||

|

||||

|

Re: Heli-Coil Usage

|

||||

|---|---|---|---|---|

|

Home away from home

|

Has anyone thought about going to 1/2" bolts? Hudson did this on their racing engines with no ill effect. The only major problem that I see from it would be the head gasket bolt holes needing to be enlarged, which could get a little tricky if you don't know what you're doing. The head in contrast would be easy to enlarge.

(This is all providing there's clearance to the water jackets in both the head and the block)

Posted on: 2010/10/19 13:20

|

|||

|

||||