|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

One more hijack and then back to 1940. It is amazing the essential things that were available then that no self respecting teenager could do without. Dad didn't often let us do much shopping in Albuquerque since most all the trips were on his or mothers itinerary. I missed that emporium. The local Western Auto carried a fair amount of indispensable money wasters as did the Pine Knot gas station. You could buy the portawalls individually there and pay for them on the layaway plan -- just hoped another wasn't trash before the first replacement was paid for. Of course, there was always mecca -- the JC Whitney catalog if you could afford a money order.

Kind of funny now thinking back -- most in my crowd could barely afford gas but always seemed to find money for chrome & dress up items or something to make the cars go fast or a gadget guaranteed to make the car run like new and get you phenomenal gas mileage at the same time.

Posted on: 2011/11/9 19:10

|

|||

|

Howard

|

||||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Great Porta Wall stories! They are as hokey as it gets, and I just love the stories about using them as a youngster.

After all the work to mount the fresh spare , I decided to give it a bubble balance before putting back in the car. Only took an ounce of weight. Other than that, chased some trunk rattles out of the trunk area.

Posted on: 2011/11/9 23:03

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Webmaster

|

Tires look great. I have to get me a of those for the clipper. I am sure the radials drive nice, but they sure don't have the right look and right height as compared to those. Just love the scalloping at the edges.

When I got my Clipper, the spare tire was that style, but it was horribly dry rotted.

Posted on: 2011/11/9 23:53

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Well, it's been a while since doing much Packard work. Both cars performed flawlessly in Laughlin and I've been content to enjoying driving them for the last month. The one glaring difference between the '39 & '40 was the void of experiencing motoring ecstasy when pushing in the overdrive knob, letting off the accelerator pedal, and feeling the big Super 8 loaf effortlessly.

Somewhere in this thread, I believe mentioning acquiring a complete R-11 out of a '49 from Packard Info. member Tommycourt. This is the identical installation I performed on the '39 about four years back and have been 100% satisfied. Today, my friend Bob and I degreased parts, lubed and serviced the OD cable (which will require a little additional TLC) and bagged parts for use in the installation. All turned out well, with the transmission and parts cleaned up. I will get seals and gaskets this week and begin to address the electro-mechanical side of the installation. The tranny presently has the long solenoid which is a bit close to the X-member. As luck would have it, Big Kev acquired a short R-11 solenoid while at Pauls this summer. I will work to have everything pre-staged so the install can be carried out in the week during Christmas and New Years. I will shorten the driveshaft on the big lathe after the tranny is installed as I did on the '39.

Posted on: 2011/12/11 23:14

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Webmaster

|

Can't wait ride in the '40 again with OD!

Posted on: 2011/12/12 0:39

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Home away from home

|

Do you have detailed photos of your work to shorten the drive shaft? Just curious. A very good shop here in Dayton told me they would do the work for around $75-100 (not for me, a friend). Does that seem too cheap?

Posted on: 2011/12/12 7:57

|

|||

|

West Peterson

1930 Packard Speedster Eight boattail (SOLD) 1940 Packard 1808 w/Factory Air (SOLD) 1947 Chrysler Town and Country sedan 1970 Camaro RS 1936 Cord phaeton packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=4307&forum=10 aaca.org/ |

||||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

West, if I end up using a mystery shaft from the January PI swap meet, then no pics, if it's the wrong length, then yes I will post pics as time allows. No, $75 - $100 is not at all out of line. $200 usually gets a brand new assembly with U-Joints.

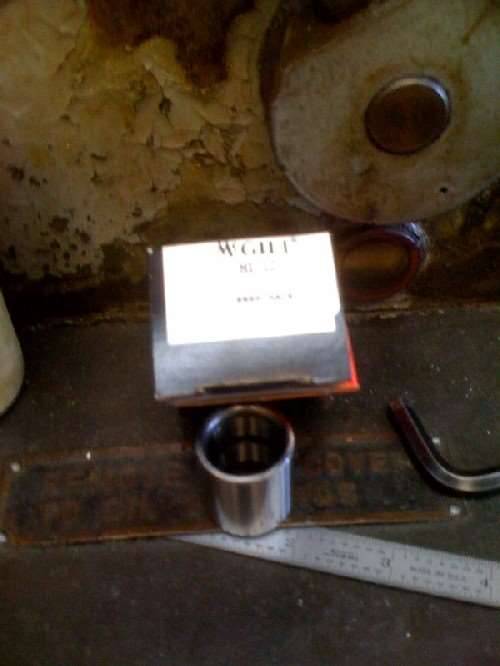

So, I began by tearing down the trans to install the senior large input so it would work behind the 356. The farther I got in, the more sketchy things looked. I found that some parts had previously been replaced before the car was parked, others had not and were in terrible shape. The good / bad news is the relay has a break in the .010" electromagnet winding so the OD was inoperative. The OD section is virtually perfect but I have a bad relay. Looks like I'll be rewinding it one evening in the near future. Upon inspection I discovered first / reverse slider had badly worn shift dogs from some jerk jamming gears along with the second / high syncro shifting collar. Not a real problem, I have good parts from a tranny that came with the spare Flackmaster found me in Oregon about 3 years ago. Thanks Dave! Next disaster was finding the mainshaft bearing surface the needle roller bearing runs on at the front end of the main shaft was half perfect and half pitted and badly worn. Looked like improper hardening from new. What to do??? The freewheeling first and second gears were perfect and they are held on with a swaged collar as Packard only sold this main shaft as an assembly. There is likely no storehouse with Packard mainshafts for transmissions equipped with R-11, so it's out to the lathe yet again. I located a bearing sleeve that is 1" OD X 3/4" ID by 1" long. Absolutely perfect! My buddy John brought some high speed carbide tooling over and we proceeded to cut through the hardened bearing surface and reduced the shaft size to accept the new bearing journal. As the tooling was cutting it became positively obvious there was an error in the hardening process as evident by the way the tooling cut on the unworn section v. the damaged section. With the mainshaft salvaged, bearing fit, and input tested for fit, it was on to something a bit less stressful and a bunch easier to fix, a little switch so to speak. Read all about in the next installment of "How would anyone fix these cars without a machine shop in their garage". Attach file:  (47.63 KB) (47.63 KB)  (46.58 KB) (46.58 KB)  (47.94 KB) (47.94 KB)  (34.40 KB) (34.40 KB)  (39.81 KB) (39.81 KB)  (32.06 KB) (32.06 KB)  (41.87 KB) (41.87 KB)  (45.57 KB) (45.57 KB)  (47.49 KB) (47.49 KB)  (46.60 KB) (46.60 KB)

Posted on: 2011/12/29 0:12

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

As promised, a little switch. I thought the kickdown switch I got with the tranny was good. It wasn't of course. No problem, you can adapt a Ford kickdown. I got the new switch boxed by Borg Warner only to find it marked as made by Cole Hersee. The original Packard kickdown was made by them also. I thought "I wonder if the guts are the same" and "wouldn't it be neat if I could rebuild the Packard kickdown with this switch". The answers is yes! Happy days. The switch on the left is one I found while digging through the R-11 annals and believe it to belong to Flackmaster, but won't know till he's back in country. The one on the right is my stripped down Packard by Cole Hersee and the middle is the readily available Ford OD kickdown. The pictures tell the story with assembly complete and continuity test proving the results of proper function. This was fun!

Posted on: 2011/12/29 0:25

|

|||

|

||||

|

Re: 1940 Super 8 160 Model 1803 Project

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just catching up on what's new with the OD project. No joy getting done last week, the journal roller bearing did not come in the Friday before New Years weekend. So, other work proceeded.

First up was repairing the broken OD cable sleeve. It is a brass tube and was bent. It snapped when straightened so a sleeve was needed. No problem, a 3/8 fuel line did the trick. Next was bad second / High gear bronze shift fork pads. The pads are swaged onto the forks. Had spares but wanted to avoid changing the whole fork. Found that I was able to grind the washer off and split it leaving a groove that an E-clip worked perfect in. Easy fix. Needless to say, this thing was popping out of gear and being held in with the shift lever. On to adding magnets to the drain bolts. Easy task that will pay off in spades down the road. Next I found the pins and pivots associated with the throttle linkage were loose enough the car didn't get full throttle and would not depress the kick down switch properly. No problem, make oversize pivot pins. More to come... Attach file:  (46.44 KB) (46.44 KB)  (49.57 KB) (49.57 KB)  (48.98 KB) (48.98 KB)  (47.71 KB) (47.71 KB)  (31.80 KB) (31.80 KB)  (36.55 KB) (36.55 KB)  (43.26 KB) (43.26 KB)  (30.49 KB) (30.49 KB)  (45.12 KB) (45.12 KB)  (38.34 KB) (38.34 KB)

Posted on: 2012/1/8 0:58

|

|||

|

||||