|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Home away from home

|

What is the composition of springs used in modern day MC's???

What ever that composition is should be appropriate for the BTV spring. I don't know.

Posted on: 2010/6/18 9:57

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Home away from home

|

As for the corrosion problem of the spring it is also a problem for the rest of the mc. As HH56 mentions a few posts above the BTV sets very low to the ground. It's vented to the atmosphere. This venting to the atmosphere needs to be overcome or the same old problems will remain after the spring issue is resolved.

I mean it's this simple: Drag something, ANYTHING barely 9 inches from the ground and it's going to fill up with contamination alot faster than if it's 18 inches from the ground. Seal it up!

Posted on: 2010/6/18 10:04

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Home away from home

|

I suppose my leary attitude toward the drain and flush of the entire brake system has to do with the relative ease towhich it has been referenced from time to time. A few weeks ago one P'info participant indicated about 20 minutes to do the job. That makes me wonders about the specific details of the task.

LEt me get real specific: If the WHEEL CYLINDERS are not DISASSEMBLED to remove the excess of fluid in the wheel cylinders then the entire process is rather an effort in futility.

Posted on: 2010/6/18 14:10

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Home away from home

|

Let us consider a 1" wheel cylinder. The cups are most likey 1/2 inch apart.

So each wheel cylinder holds 1/2 x (1/4 x 3.14) = 0.4 cubic inches of fluid. Times 4our wheel cylinders = 1.5 cubic inches of fluid total. That would equal to about 50 inches or 4 feet of UNflushed 3/16 brake line which is about equal to 1/2 of the brake line going to the rear axle. A bit excessive residue in my book realtive to the popularity of procedure. What am i missing???

Posted on: 2010/6/18 14:25

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

How much of the residual fluid would actually remain though? Assuming it was done on a routine basis, doubt it would have crystallized -- so with an inlet and the bleed screw usually above it, would think that the vast majority of the old would be flushed out--

I do see the benefit of removing drums though just to get a look at things and make sure the rubber or something mechanical hasn't fallen apart or hasn't sprung a leak not showing yet.

Posted on: 2010/6/18 14:34

|

|||

|

||||

|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Home away from home

|

I usually end up using about a quart of fluid for a good thorough flush. Suck the master dry with a baster or whatever, fill with fresh fluid and bleed the cylinders one at a time til they run clear. The idea is just to keep fresh uncontaminated fluid in the system to keep a good system good. On the lift I can do it in 20 minutes. Less with a helper. It will not be a help to systems where corrosion is well underway or crystals have started to form. The horse is out of the barn by then.

Reminds me its time to do the 60 Lark again. I rebuilt the original cylinders when I inherited the car 24 years and 63,000 miles ago. Still OK.

Posted on: 2010/6/18 21:25

|

|||

|

||||

|

Re: BTV blues...

|

||||

|---|---|---|---|---|

|

Home away from home

|

If i were compelled to do a drain and flush i believe a vacuum pump (with glass reservoir) connected at the bleeder screws would most likely be the fastest,easiest and most thorough way to do it.

Based on my limited experience with single line UNsealed systems on daily grocery getters that were often 10 to 15 years old during the 70's and early 80's, i found that hte brake fluid would usualy begin to run clean rather fast during a routine brake bleeding procedure when the wheel cylinders were serviced for symptomatic problems. They were MIchigan/Ohio cars too. But all that i can remeber is that they had mc's mounted high on the firewall. None were frame mounted except maybe a Jeep or two. In nearly all cases when worn shoes are replaced the wheel cylinders have to be disassembled for cleaning or honing or MAYBE replacement. THis is due to the new shoes pushing the wheel cylinder pistons back in further into the wheel cylinder. In those cases i found that the corrosion was mostly limited to the wheel cylinder area. Once the pedal was pumped just once clean fluid issued almost immediately (mc not yet replenished with fluid) . I have found this to be the case in nearly all brake systems whether sealed or not, single or dual. Especialy on systems with 50K miles or more and over 6 or 7 years old.

Posted on: 2010/6/18 23:26

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: BTV blues...12/3/2011

|

||||

|---|---|---|---|---|

|

Home away from home

|

Gents and Ladies,

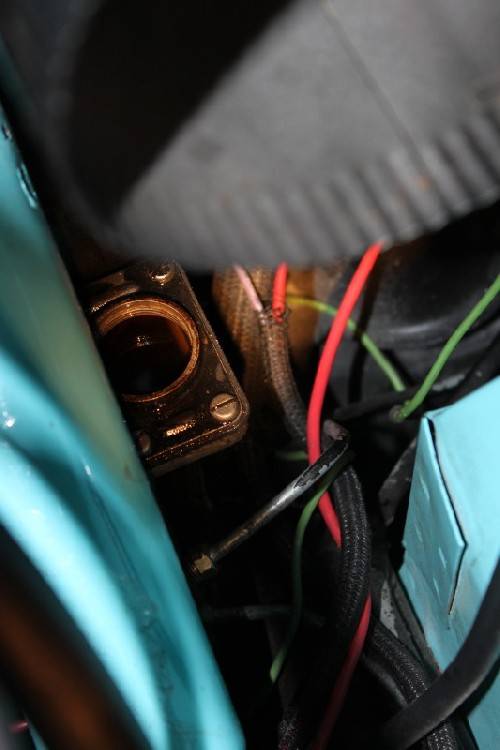

Today I started the 400 and let it warm up in the garage. Temps here have been cold for us over the last couple of days. Anyway, I proceeded to back the 400 out the garage and down the slight incline on my drive, when I noted a very mushy brake pedal. I pumped and used the e-brake to stop the car. The pedal immediately pumped up hard. I drove the car back inside the garage and checked my brake fluid. It seemed down a bit low, so I added about 2 -3 ounces. I also noted that the surface around the filler cap was wet. I buttoned things up and drove the car a few miles. Out on the road I had it go mushy once again, but it pumped up again. I came back to the house and again checked the BTV. Moist residue noted around the cap again, so that got me thinking (a dangerous event according to my wife). I looked at the filler cap and noted that the gasket seemed to big. It was sloppy, especially when filler cap got tightened a bit. I then took a look an an old BTV I have on a shelf and noted that the gasket seemed a bit big on that filler cap too. Then closely inspecting both caps I noted a difference. The cap on the 400 has a small hole on the edge (as seen in pictures) and the other unit does not. Well, gents and ladies this what I done. I decided to use the filler cap without the hole and I placed an "O" ring around the threads to act as a gasket, hopefully 'sealing' the cap so I get no more seepage from around the cap. Here are my questions. 1) Is the filler throat supposed to 'breathe'? Is that the reason for cork or other gaskets that seem to squeeze outward when minimal tightening is applied to the cap itself. 2) As the 400 filler cap had a hole on the edge and the other didn't, what purpose do the 'vents' on the underside of the filler cap serve? Thoughts and advice appreciated. ( I'm not yet ready to dump the BTV entirely yet!)

Posted on: 2011/12/3 16:51

|

|||

|

||||

|

Re: BTV blues...12/3/2011

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

For what it's worth mine is vented with the small hole like the one on left in your last picture. It's missing the gasket but has never leaked. I would look closely at the compensator valve and relief port. To have a mushy pedal that recovers -- that valve or a leaking piston rod seal are about the only items that would contribute. Maybe leave the cap off and have someone pump the pedal while you watch to see if fluid is squirting back into reservoir from the valve or spraying the lid from a leaking seal thru port.

Posted on: 2011/12/3 17:05

|

|||

|

Howard

|

||||

|

||||

(39.29 KB)

(39.29 KB)