|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Home away from home

|

In SOME (which means NOT All) applications, especialy aluminium, the FEmale threads in the block are also recessed by 2 or 3 threads meaning that there are NO threads at the top 1/32 to 1/16 inch of the surface of the block. This ia also done to keep any distortion at the surface of the block immediately surrounding the female threaded hole from mushrooming up.

Posted on: 2012/2/18 8:33

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

Agreed but still kind of curious why Packard would say they are not interchangeable with the older studs and must only be used on blocks so equipped from the factory. Wonder if there is some differences in the block along the lines PV8 mentioned.

Posted on: 2012/2/18 14:12

|

|||

|

Howard

|

||||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I would assume the difference is the "fullness" of the thread cut(75% thread, etc.) or perhaps the profile of the thread in the block to accept rolled threads.

Even though both are nominally 7/16-20, try a rolled thread stud into a prewar block, or visa versa and I suspect you'll have your answer.

Posted on: 2012/2/18 16:19

|

|||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I know they thread in with some difficulty which is why I raised the question. I believe you can see the difference in the photos with the shape of the thread. On the bolt website explaining the difference, they make it seem to be minimal and ones made today interchangeable. The repro stud to me looks like a cut thread with body the same diameter and if so, would expect there to be some issues--yet Max says none reported. I'm just trying to understand what I'm missing and why you cannot interchange one way but apparently can the other. The profile in the block is what I'm thinking but never really paid much attention.

Posted on: 2012/2/18 16:29

|

|||

|

Howard

|

||||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Home away from home

|

What strikes me as odd is that the article states that the NEW (rolled) is NOT i'changelable with old (cut) studs and that NEW can only be used in the new engines mfg'd for NEW stud. It begs the question as to whether or not the the OLD stud can be used in NEW engine too.

One would have to study the old engine vs new engine stud holes for any recess or lack of recess of the female threads in the blocks. And study the variation of studs as old vs new. The article states that the NEW stud was developed to prevent water leaks. I kind of doubt that since i'm fairly sure that permatex was available at that time. Most likely the stamped,pressed or rolled stud was for a strength issue at where the thread ends at the shank of the stud, allowing the threaded portion of NEW stud to set a thread of two below fire deck of block and also the rolled thread cheaper to make. NOTE that any DIE CUT MALE thread usualy requires the die to be turned upside down to complete the cutting of the last 1 to 3 threads of any application.

Posted on: 2012/2/18 17:32

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

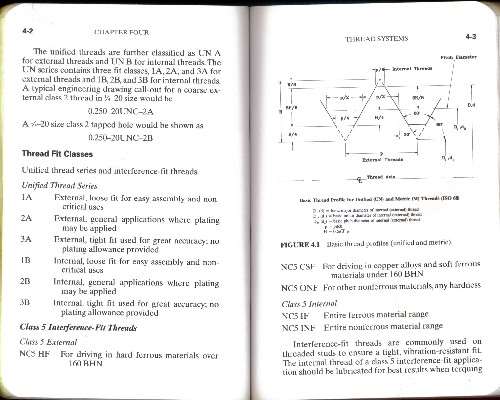

HH, if you've got a good machinist's manual or handbook, you might want to check under "interference" theads for studs. There are a couple of classes of fit defined in my handbook for both internal and external interference-fit threads; perhaps rolled threads fall into this description. They are fuller threads and use of a lubricant to install them is recommended.

Posted on: 2012/2/18 17:43

|

|||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Home away from home

|

QUote:

"I know they thread in with some difficulty ..." Somewhat begs the question as to whether or not the NEW stud was delveloped with an interference fit thread for LOCKING purposes rather than leakage. My 1948 2262 has a THIN flat washer under the NUTS. Only about 1/16 inch thick is the washer. So i assume it is NOT a HARDENED washer. But then again i don't know if my washers are OEM or not, I'm guessing they are. So one mite need to study NUT washer differences between those used on OLD studs and washers used on NEW studs. If the OLD stud washers were THICK HARDENED steel and NEW stud washers thin and therefore not hardened then the interference fit of thread would be for locking purpose and not leakage.

Posted on: 2012/2/18 17:44

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Home away from home

|

Whether OLd or NEW stud, do the studs screw down into the block in such a way that NO thread is sticking up above the deck of the block????

Rolled stud have LESS threads than cut stud???

Posted on: 2012/2/18 17:56

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Several questions...

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

PackardV8

Yes to the first, they are not blind threaded holes. No to the second, at least not significantly so. As to "Class of Fit" for interference threads, this from Ronald A. Walsh's "Machinist's and Metalworkers Pocket Reference", published by McGraw-Hill:

Posted on: 2012/2/18 18:37

|

|||

|

||||

(117.14 KB)

(117.14 KB)