|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

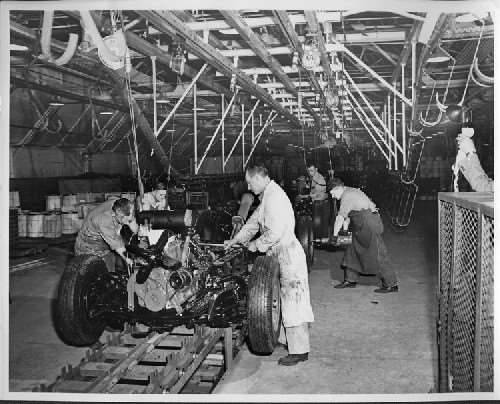

Gator, there are MANY such pictures, all you need to do is seek them out. One primary source for many factory photos is the "Making of Modern Michigan" collection at the Michigan State website; Big Kev received permission to put these on the site here, so you can view them at either site. Another source is the Detroit Free Public Library, where the engine block casting picture comes from. And there are many other sources of such photos, there are some good ones in the Kimes-edited book.

PS - the assembly line process was managed in postwar years by a teletype system - those "build slips" we find are teletype instructions for the line.

Posted on: 2012/3/6 18:31

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

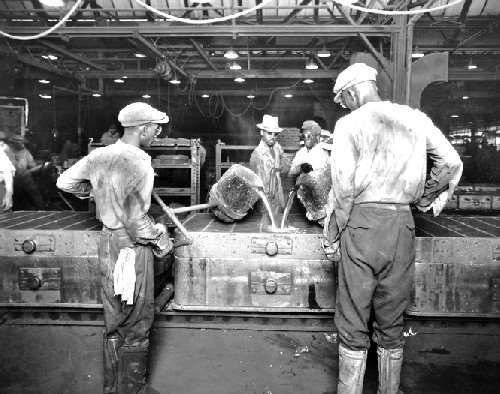

The photo of the foundry workers hand shanking the moulds brought back some old memories. We used to do that for small castings, but used a crane for the bucket on the larger ones. It requires that both of you work in unison and have steady hands. Does anyone know what a cope and a drag are?

And thank you Dave for the teletype instruction piece of information. I never knew that.

Posted on: 2012/3/6 20:34

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Home away from home

|

Randy or Dave, I always assumed the blocks were cast in sand moulds but obviously not, how does the process shown in the photo work? was the block casting an assembly line process as well and I assume after rough cast was accomplished then the final machining was completed and then engine assembly? Kind of like a whole "sub-assembly" line. Anyway, as for hauling the Briggs built bodies to the various auto manufacturers, I found this interesting post on the AACA site from a senior member by the name of Tom Deering who had lived near Detroit "back in the day" and also stated that he had family that worked at Briggs:

[/quote] No one on this thread or the Packard thread has mentioned the new Packard plant on Harper Ave. just down the road from the original E. Grand Blvd. plant. I thought their post war car production was done there. Their test track was in Utica but I didn't realize there was any assembly performed at that site. Last time I was there in 1974, it was a Ford facility.<P> But back to Briggs. Your assumption of Briggs facilities being close to their customers plant is correct. Chrysler Jefferson Assy. and Hudson also on Jefferson Ave., were serviced by the Briggs Mack Ave. plant. The Briggs plant on E. Outer Drive fed the Dodge plant on Jos.Campau and the Plymouth plant on Lynch Rd. I never did understand how DeSoto got its bodies way out on the west side on Wyoming Ave. The Packard plant was mid-way between the two Briggs plants. I'm using street names just in case somebody wants to refer to a Detroit map.<P> You mentioned logistics problems in moving bodies from the vendors to the customers assembly plant. The '55-'57 T-bird "Bodies in White" were produced at Budd Mfg. on the east side on Warren & Conner and trucked to the Ford plant in Dearborn. Never understood how those bare bodies could be shipped on an open trailer across town in the rain and snow and expect to have paint stick to them.<P> Finally, Walter O. Briggs, Briggs Stadium and the Detroit Tigers. That was a Detroit institution during the '30s, (don't know when it started) '40s and '50s. Went back there in the '60s and the stadium was repainted an ugly gray and its name had been changed to Tiger Stadium. <BR> Now you know how Detroit streets got so beat-up. The whole town was one big assembly line.[/quote]

Posted on: 2012/3/7 11:17

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Webmaster

|

Wasn't there a PAC article on the Briggs plant a couple of years ago that had a lot of pictures (circa 1954) that were provided from the Chrysler/Briggs archive?

Posted on: 2012/3/7 11:20

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The Packard plant on Harper Ave was their foundry and forge which was sold during 1954.

The picture of the casting operation is dated 1928; I don't believe the boxes are large enough for blocks - I had (perhaps incorrectly) assumed they were casting the aluminum crankcases in that photo. Purely a guess.

Posted on: 2012/3/7 11:26

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Home away from home

|

This video is very neat. It shows 1936 automotive assembly line. It isn't Packard, but is neat to watch if you are interested in early automotive assembly lines:

dump.com/2011/07/15/fascinating-1936-footage-of-car-assembly-line-video/

Posted on: 2012/3/7 13:46

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Fascinating doesn't even do that video justice! WOW!...now that is American ingenuity in its finest hour! It isn't enough that they could actually manufacture a piece of raw steel or sheet metal to make something with but they had to design and build a machine that would actually transform it into something with purpose and function. How could anyone not be amazed at what the generations of our fathers and grandfathers accomplished in just 36 years after the turn of the century???...from oats to gasoline in the blink of an eye! That video is astonishing portlandon, thanks for posting the link!

Posted on: 2012/3/7 20:46

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Home away from home

|

That article was "Conner, Briggs, and Chrysler" by John M. Lauter in TPC #126 (Spring 2007)

Posted on: 2012/3/7 21:02

|

|||

|

||||

|

Re: Assembly Line Info and Photos

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

That video is quite the thing and makes one appreciate the amount of labor that went into manufacture then. The one guy standing between those huge machines sliding in and out inches away on either side of him must have had nerves of steel. Hopefully he never took a step in the wrong direction. I expect an OSHA inspector would have a field day if it were done today. Probably need to have so many safety interlocks it would be having a reset every time someone sneezed.

Posted on: 2012/3/7 21:17

|

|||

|

Howard

|

||||

|

||||

(93.16 KB)

(93.16 KB)