|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The flocking fibers found today are much finer in texture than the rayon fibers Packard used. About as good as you can find will be nylon fibers which are coarser than todays rayon but still nowhere as large as the originals.

There were apparently different color blends used over the years. Pre 51 seems to have been more brown shades while 51 on seemed to go grayer. You can try to match your car by getting a few different base colors from Flock It and mix the blend yourself. The finish will be quite presentable and better than bare metal or just the sound deadener but any new application will still be noticeable if you have any of the old flock visible.

Posted on: 2023/6/1 14:57

|

|||

|

Howard

|

||||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Thank you! This sounds like a fun/crafty project and a good way to keep my car looking original. I'll dig around a bit in my trunk and see if I can figure out just what colour it was originally and try to match it.

Posted on: 2023/6/1 16:06

|

|||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

53 Cavalier;

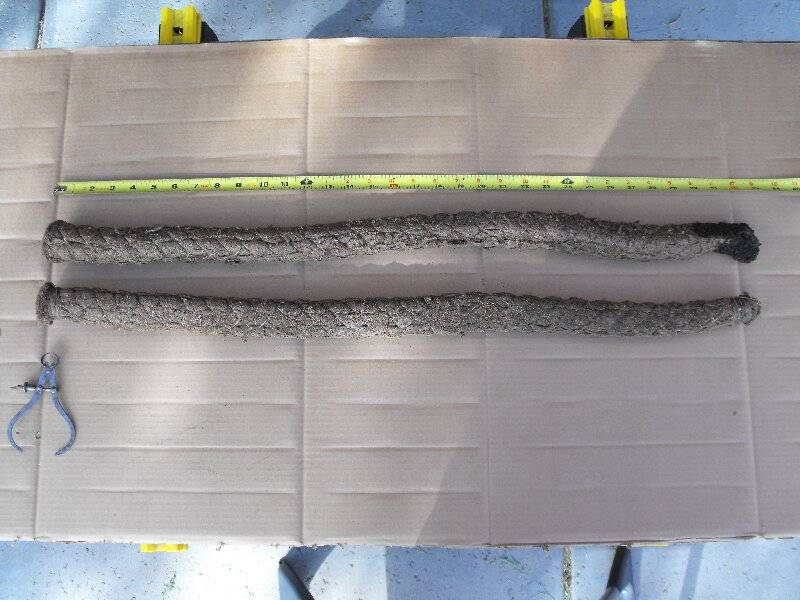

I believe the 26th and 54th (perhaps 24th to 54th) series trunks were finished with the following process: All of interior surfaces of the trunk were sprayed with an undercoating material. The amount of material applied likely varied with location, with the inner surfaces of the rear quarter panels receiving the most, and the spare tire well receiving the least (if any). I believe this coating would be identical to the coating used to adhere the interior sound deadening pads. I’m interpreting the entire surface was sprayed, but I can’t tell unintentional over-spray from an intentional light coat. I believe the goal was to provide more corrosion protection than paint alone, so I’m leaning to the entire trunk was intentionally sprayed. Flocking material was then applied to the interior surfaces, with sufficient flocking material applied to those areas with a ‘heavy’ undercoating to completely cover the undercoating. If an area was going to be covered with a mat/pad/carpet then the flocking would not be applied, and hence the thickness of the undercoating minimized. The next obvious question is what currently available materials would produce the same (or close to) the OEM look and feel. I think just about any black in color roofing cement, or automotive undercoating would be close to the original material, which was/is to encapsulate the steel and thus retard rusting, and be a suitable adhesive for the flocking. POR could also be used if the surfaces are corroded, but that product may be too thin for flocking. The key characteristic for this material is the drying time . . . this material cannot dry in the amount of time it takes to flock the surface. The flocking is another subject entirely. The flocking that survived in my ’54 was inspected under relatively high magnification that revealed a multi-color, multi-length mix of fibers. I read somewhere that the material was goat hair, which would explain the variation in both color and length. The colors ranged from white to black with the majority being tan/light brown. There were a few translucent fibers amongst the mix. The lengths varied in the 1/4 to 3/8 inch range . . . mostly, but there were a few longer and shorter. I realize that I had just vacuumed a 60+ year old car, and was sensitive to the problem of how much of the captured material was modern ‘debris’, and how much was OEM flocking. When I went looking for modern flocking I ran into many choices of color and length, so if my sample to flocking is genuine, many lengths and colors should be blended to mimic the OEM material. If the OEM material was goat hair then I would expect some car to car variation, and perhaps some seasonal variation. Given my sample of flocking fibers I would agree that the overall color would be in the tan/light brown category. The trunk floor on my ’54 had a three piece pad made from ‘tar paper’. The pad was comprised of one rather large piece that covered the floor from the spare tire wheel well to the driver’s side of the trunk floor. It also went from the rear of trunk floor to the beginning of the ‘hump’ for the rear axle. This piece had cut-outs for the various reinforcement gussets along the rear wall of the trunk. Another piece of tar-paper went from the other edge of the spare tire wheel well to the right rear fender. IIRC there was a cut-out for the tire hold-down bolt details. The final piece was filled in the gap between the other two pieces. It is roughly the width of the spare tire well, and filled the gap between the well and the aft wall of the trunk cavity. The piece had a curve to match the well. The three pieces of ‘tar-paper’ were stapled together. I have assumed this covering was to provide some protection from moisture and to protect the fiber-mat/carpet from getting mucked-up from the undercoating. I’m assuming based on the die-cut details this tar-paper pad is original. I have never seen an original upper fiber/carpet pad. My car had an unfolded jack box as an upper pad (ugh!). The void between the rear quarter panels and the outer surface of the wheel tubs was filled with ‘fiber ropes’. My ’54 had what I believe are original items. They are approximately 33 inches long, and 1 ½ inch in diameter. While we use the term ‘rope’ they were made of short fiber paper . . . a lot like crape-paper. The paper was formed into the ‘rope’ such that no edges of the paper were visible, which suggests those edges were facing inward. It also looked like many pieces of paper were ‘stacked’ into a pad prior to folding to hide the edges. A double over-braid of thread with a pitch of approximately 1 inch held the paper bundle together while the ‘rope’ was in storage. The over-braid was a double counter wound configuration that produced a repeating ‘diamond’ pattern. While the ropes for my ’54 had the ends wound with a different type of thread, I don’t believe this was the OEM configuration. I envision a dispenser that would hold many yards of material, and upon activation would dispense a piece of material cut to the correct length. The installer would grip the free end of the material inhibiting the thread from unwinding, and in very short order the material was forced into the fender/tub gap. In my two examples I could not find an obvious splice/gap in the length of the crape-paper, suggesting either those details did not exist in my units, the folding technique could hide those details, or the length of the crape-paper established the length of the final product. Tire kicking wisdom suggests the ropes were installed to inhibit small items from falling between the fender and tub. While this is likely true I believe there is also an argument that could be made for quarter panel support . . . but I do lean to the small item explanation. My ropes did not appear to be flocked . . . but if they were installed just after the undercoating step there would be zero adhesive for the flocking to stick to the ‘ropes’. There was little evidence of undercoating along the length of the ropes suggesting the flocking was applied before the ‘ropes’. I’ve included a few photos of the flocking material, and details of the ropes. You are right about a fun/crafty project. EDIT: Make that crepe paper not crape paper. dp

Posted on: 2023/6/1 19:45

|

|||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

Some cars used a a material that appeared to be made from fiber waste from some kind of textile mill or carpet mill or clothing factory.

Posted on: 2023/6/1 22:14

|

|||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

DavidPackard;

THANK YOU for the in depth explanation!! I pulled out the stinky gold carpet tonight and was pleased to find the trunk pan is very solid, just a bit of corrosion in the corners under the tail lights. From what I see in my trunk I would agree with your assessment. My trunk floor and wheel tubs have no undercoating, only the seams are sealed. Lots of undercoating on the quarter panels, but little to none on the wheel tubs. Most of the "ropes" are still present and intact in my trunk. I would tend to agree that they are not structural as they are quite soft. They would certainly keep things from falling in the crack and maybe they helped with sound as well. I too think there were installed last as they do not appear to have any adhesive on them. I was able to gather up some flocking and while its hard to account for how dirty it might be, I think the colours are as you describe. I saved a little bag of it. I don't have the "tar paper" under pad, but what I did find was two grey vinyl type die cut trunk pads that I can only imagine are factory. They are a little stiff, and they had glued the carpet to them in a couple of places, but I'm going to try to clean them up. I might laminate them to something to keep them from breaking up. I don't have anything that covers the hump and not sure what would have been there originally, maybe another piece of vinyl.... The hump is not coated and has little paint on it. Not sure what I'm going to do with it yet. I think the flocking could be goat hair so I've got my clippers charged and now that it's dark out I'm going to go visit one of the local farms and give some goats a hair cut! LOL Attach file:  20230601_212935.jpg (383.23 KB) 20230601_212935.jpg (383.23 KB)  20230601_212849.jpg (430.39 KB) 20230601_212849.jpg (430.39 KB)  20230601_212920.jpg (254.17 KB) 20230601_212920.jpg (254.17 KB)

Posted on: 2023/6/2 0:41

|

|||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

Goat hair is also known as "Mohair". There may be a source for Mohair pile, or knap, or whatever they call the fuzzy part of Mohair cloth.

Posted on: 2023/6/2 9:05

|

|||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Well that's a fun fact! Learn something new every day! My first thought was that can't be true, don't goats have course hair??? Well they do, but no Angora goats! But now I feel bad, I shaved the wrong goats last night! LOL Thanks TxGoat!

Posted on: 2023/6/2 9:27

|

|||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

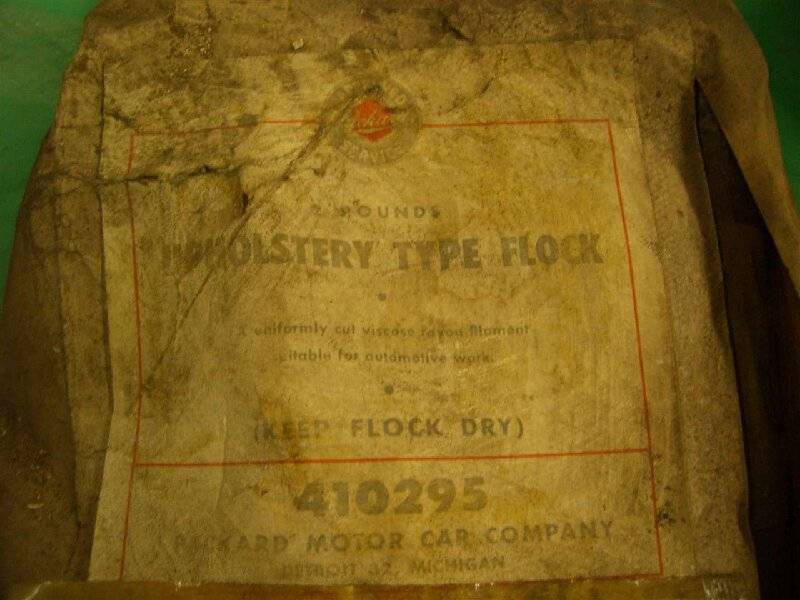

I don't remember who first posted these photos but possibly it was BDeB. I grabbed a copy of them in 2012.

The flocking package says the material is rayon and the photo of the trunk, while of a pre 51 model, shows how most of the trunks were finished. Based on the photo in the data book I believe 51-4 was finished in a similar fashion with the possible exception of no flock and just an embossed surface on the cardboard covering the seat back on lower end models. The mat also had a carpet like finish, some have said it was hogshair, and it was very thin -- almost like a couple of layers of canvas thick. In 55-6 they stopped the flocking and went to cardboard to cover the sides with a mat covering the entire floor including the hump -- at least in senior models. The mat, while still thin, had a smooth patterned surface.

Posted on: 2023/6/2 9:28

|

|||

|

Howard

|

||||

|

||||

|

Re: Factory Trunk Finish

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

With how my trunk currently looks this would make sense, that is, flocking sprayed most everywhere with a mat to protect the floor of the trunk, as BigKev had suggested.

Posted on: 2023/6/2 9:36

|

|||

|

||||