|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi Folks:

I'm not sure why choosing tiny teeth on gears that are clearly oversize represents an engineering advantage, except that perhaps the horsepower load is decreased, and that oil pressure in a worn motor may be more stable. What I do find very interesting is the comment that number 8 rod bearing was the first to go. This is the bearing closest to the pump. It has also been the bearing that I have seen spun most often. In the Senior 8's number 2 is the rod that likes to go into orbit and is nowhere near the feed source. When I look at the pump circuit for the V-8 the feed for number 8 rod bearing is directly taken from mainline pressure before the sender. The other rods are being fed from the oil gallery. Now to do this the oil has to change direction and if you get the mainline flow going fast enough this can create a syphon action that will starve number 8 rod bearing. So maybe this Oldsmobile pump with fewer teeth leaves a few milliseconds of reverse pulse that interrupts the tendency toward suction and therefore rod bearing failure. The bonus for the lifters maybe that there is less aeration of oil with the larger teeth. How about that?

Posted on: 2011/11/19 16:27

|

|||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

Owen_Dyneto Quote:

Craig: I'm curious, do you know the volume of oil discharged by the Olds HV pump per shaft revolution versus the original Packard pump? No, I do not. It would take some precise measurements to accurately calculate same. But, given that the Olds HV gears are both wider and longer, I'd guestimate a conservative 20% more. Craig

Posted on: 2011/11/19 16:39

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

Tim Cole Quote:

So maybe this Oldsmobile pump with fewer teeth leaves a few milliseconds of reverse pulse that interrupts the tendency toward suction and therefore rod bearing failure. The bonus for the lifters maybe that there is less aeration of oil with the larger teeth. Respectfully, as an engineer, I think you are completely out in left field with these suppositions. Craig

Posted on: 2011/11/19 16:41

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

Then I respectfully suggest an explanation of this problem that avoids superstition.

I will remain mum as to my academic background.

Posted on: 2011/11/20 10:19

|

|||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Noise from lifters that are otherwise clean and in good working order is clearly due to insufficient supply of oil, but the cases between the Super Eight and the V8 couldn't be more different.

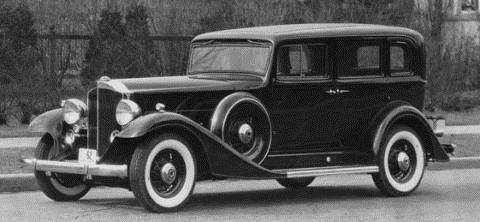

If one considers the service engineering history provided by the relevant <i>Service Letter</i> articles that were published from 1940 through 1947, it becomes apparent that Packard was trying to improve oil supply to the lifters in the Super Eight engine, but ultimately settled on a pump that provided higher volume. Thanks to <i>39super8</i> (Jim), we now know that this was accomplished by gears with a deeper root, plus a larger discharge opening. In spite of that business about bearing clearances opening up, this new pump became standard issue on the '48 Custom Eight engine, which was actually the old 356 mill from the Su8. Yet, if you look back through the parts books, you'll find that the pressure relief valve spring is the same in this new pump as all those before it in this engine. All this suggests that Packard had simply underestimated the additional demand of the new hydraulic tappet technology in their initial oiling system design. The problem with the V8 is bit more complicated. After a new lifter design and a few various attempts to modify oil supply to the lifter galleries for the Packard V8, they somehow determined that air was entering the oil stream. Initially, it was though that the source was the pressure relief valve port, while the valve dumps oil internally, there was concern that the vale was sticking, and allowing air to be drawn in on the suction side. After and extensive field test that involved plugging pumps, Packard revised the production oil pump to a plugged style, and with a different pressure valve and spring, but with NO change in gears. However, for field service of the earlier design, it was decided that a tube kit would suffice - such that a sticking valve would draw oil from the sump, rather than air. There must have been some merit to this approach, or Packard would not have bothered to redesign the pump body and pressure relief valve and spring. In fact, my dad put nearly 75K on the clock of the Exec that he purchased brand new in the April 1956 (which falls in the production range of the late design pump) and it NEVER had a lifter noise. In fact, he never had that engine apart for anything. <i>('Twas lack of parts and competent service for the Twin Ultramatic and the onset of tin-worm that killed the beast.)</i> However, long after the last Packard engineer turned out the lights in Detroit, reports of lifter noise in the V8s persisted. I believe it was in 1975 that PI first announced a modification service, where the vacuum pump and separator plate was removed in favor for a thicker, bushed, bottom plate. Yet, I could never accept the notion that the problem was the result of the vacuum pump and or separator plate was flexing under pressure. In fact, Studebaker had recommended the same approach as Packard for the 56J Golden Hawk which used the Packard V8 and oil pump, but WITHOUT the vacuum pump. I've even heard of reports of problem persisting even after installing a modified pump from PI. The very fact that some owners reported relief from overfilling by no more than a half quart of oil is clear evidence that some pumps were drawing air from some other point. As it turns out, it was excessive wear between the driving shaft and its corresponding bore in the pump body. Those claiming the Packard V8 pump had insufficient bushing are misstating the facts; the Packard pump never had bushing at this point - nor did many others. Bob Aller's approach to rebuilding the pump trues up the driving shaft and installs a bushing in the pump body, to fixe the leak. In fact, I personally know of a '56 Packard in this area that had such work done over a decade ago and the car is driven, not trailered, to all sorts of events, year after year, in the Penn-Ohio area - some even hundreds of miles beyond - with no further with problem. I think the root of the problem with the V8 pump was identified by member <i>PackardV8</i> (Keith Lummus). Attached, below, is a pic that he provided, long ago, at another venue. Notice the small-block Chevy pump (at left) has a cast channel that supplies a trickle of oil, from the output side of the gears, to the driving shaft, where as the OE Packard pump (at right) has none. Give the driving shaft in the Packard pump, even bushed, some oil and it should be fine. I believe that member <i>Ross</i> (Miller) is now doing this with his own rebuilds. The problem with the Su8 engine was one of mere oil supply, but the ultimate problem with the V8 is one of air diluting the oil stream. IMHO, the Olds HV conversion isn't necessary, but simply an alternative for those who want something other than a properly repaired OE pump. Yet, no matter which route an owner choose, they need to be mindful to the possibility that collateral damage has already occurred elsewhere in the engine. Simply throwing more oil at the lifters might be masking other issues. I'm no engineer, but you don't have to be a rocket scientist to see this. <i>Caveat emptor</i>.

Posted on: 2011/11/20 11:35

|

|||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

Some time back I wrote about when my father was trying to solve the noisy lifter problems in the Packard V-8s (mid-1950s to mid-1960s). He thought the problem was with the camshaft. I don't recall what he thought was wrong with them, but too fix this problem he installed adjustable push rods. He used very small rocker arm to valve clearances (I believe they were 0.001" for intakes and 0.002" for exhausts). This fix seemed to work the valves were quiet and not other problems like crankshaft bearing failures occurred. He also thought the engines ran smoother. He also installed the newly designed camshaft thrust plate.

Of course, it is 50+ years later and these V-8 engines have been subject to all kinds of driving conditions which were not in his experience. It seems now that while his fix worked there was still a core problem that had not been discovered when he was trying to solve the problem. I also recall Bob Aller saying at a Tech Session in Salado, that it was one of his service managers in Dallas that discovered the oil pump problem of air getting into the pump from wear and misalignment of the driving shaft. (o[]o)

Posted on: 2011/11/20 12:12

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

JW Quote:

I also recall Bob Aller saying at a Tech Session in Salado, that it was one of his service managers in Dallas that discovered the oil pump problem of air getting into the pump from wear and misalignment of the driving shaft. BH Quote: IMHO, the Olds HV conversion isn't necessary, but simply an alternative for those who want something other than a properly repaired OE pump. Brian, what you, JW and some others apparently do not realize is that the bottom the Packard V-8 oil pump is 3 inches above the bottom of the oil pan sump! This is with or without the vacuum pump. Not only does this cause a 3in of negative head pressure, it means that the top part of the pump gear casting is exposed to air. This is the main reason why air is introduced into the oil supply. The Packard oil pump is just a poor design because of this. No amount of "dinking around" with the pump itself will change this. The Olds HV conversion places the bottom of that pump about 1/4in above the oil pan sump, completely immersing the pump gears and eliminating the 3in negative head pressure. Add in the extra volume and the tappet click and associated bearing problems are solved. Craig

Posted on: 2011/11/20 13:55

|

|||

|

Nuke them from orbit, it's the only way to be sure! Ellen Ripley "Aliens"

Time flies like an arrow. Frui |

||||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

Craig, I understand the problem. I was just recounting earlier attempts before the cause of the problem had been discovered. I think your relatively recent contribution in co-developing the adaptation of the Olds pump is a great piece of work. But, before there was the Olds pump solution there were many who were trying to correct the problem. Let's give those people credit for trying and in some cases succeeding.

(o[]o)

Posted on: 2011/11/20 15:16

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Deja Vu

|

||||

|---|---|---|---|---|

|

Home away from home

|

A few years ago there was some talk of vacuum pumps "improperly fitted",most likely from the factory. My very original low milearge 56 Exec (34K miles when i boufht it 13 years ago) had a loose vauum pump. The screws holding it to the oil pump were loose. The pump input shaft was very difficult to turn.

Conjecture: THose that have experienced trouble free high mileage service from oem Packard pump probably had a vacuum pump that was correctly installed. OThers had vacuum pumps NOT correctly installed thus causing premature wear of input shaft to the oil pump. But even after i tightened the vac pump screws the input shaft to oil pump was still difficult to turn by hand (no significant oil resistence in pump). I agree with Craig that the entire oem Packard oil pump/vac pump set up is a weak/poor at best design. Vac pump or no vac pump. What we really do not know at this time is exactly what Aller did to the pumps other than a bushing and details of the bushing are unknown (oil grooved/ oil galley cut ala SBC pump, lock washers under vac pump screws, etc ???). AS per a PI website write up ca 1998 - 2002 i will paraphrase : " Packard V8 oil pumps were know to need rebuilding in as little as 25K miles". Does noone else remeber that from PI????

Posted on: 2011/11/20 15:37

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

https://packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

(30.85 KB)

(30.85 KB)