|

Re: Rebuilt carb issues

|

||||

|---|---|---|---|---|

|

Home away from home

|

41 Touring;

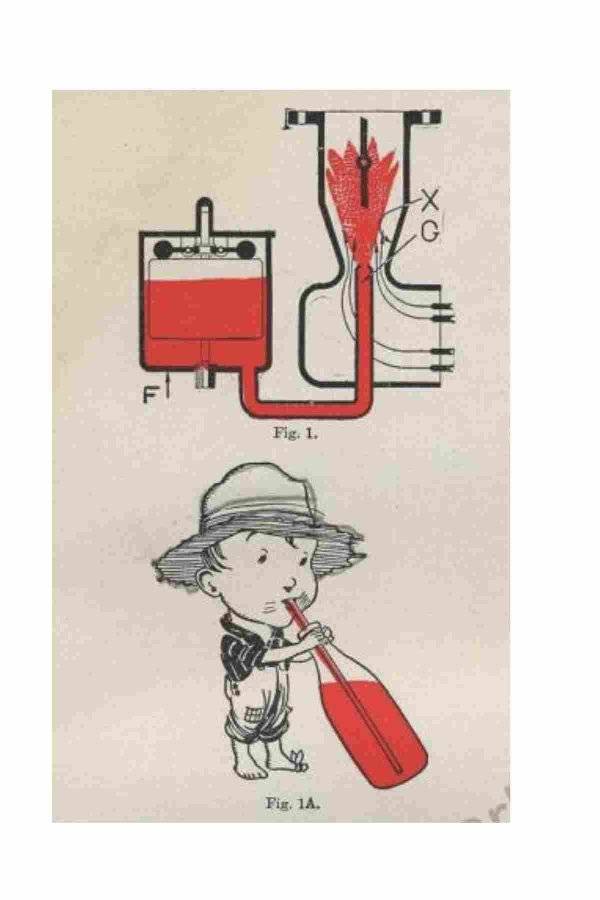

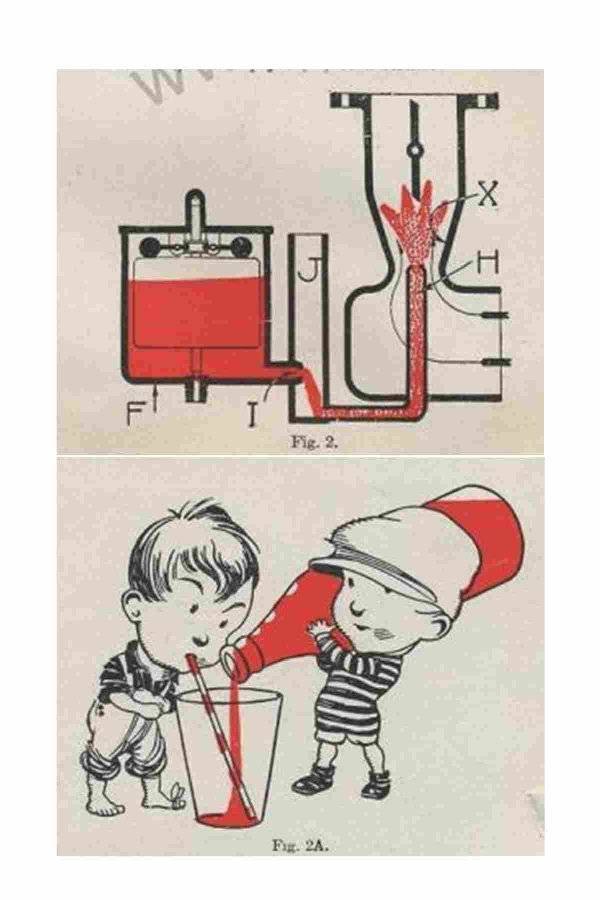

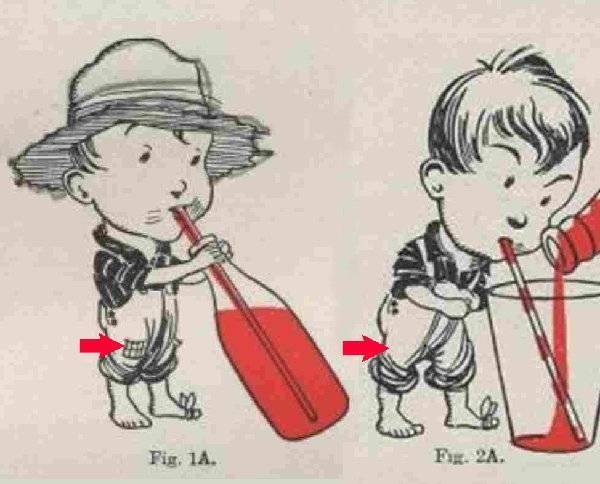

If the topic is that of the throttle plates not returning to the idle stop: I've worked on cars that included periodic oiling of the carburetor throttle shaft. You may have washed the last vestige of lubrication out of that area during the rebuild. I think we're dealing with a cast iron base and a steel shaft without bushings at that interface. You may want to try a few drops of oil. Unfortunately that interface is better accessed with the carburetor off the engine. Both of my Packard's have an 'extra' throttle return spring, and I see nothing fundamentally wrong with installing those. While my cars are not so equipped, I do like the GM design of a small diameter stiff spring inside a large diameter soft spring. If you watch the initial preload between the spring pair you can have a soft initial pedal (easy to control during clutch release) followed by a stiffer pedal feel . . . plus there is a bonus of having a backup spring if one fails. The symptom of burping the throttle to achieve low idle is common if the high idle speed is caused by the automatic choke high idle feature. You might look at that area of the linkage, bimetal spring, internal vacuum piston, or the basic setting of the choke. There is a chance that something was disrupted during the rebuild. It's a pretty small spring that swings the high idle cam out of the way so take a look at that. If the question is how to cure bad running/missing at high speed/power that's another kettle of fish, and the explanation can go on forever. Please let us know if the fuel level adjustment solved the bad running/missing symptom, and if so how much lower than normal was the fuel level. Your reply will help answer the question of the effectiveness of the percolation well air bleed. For the other followers of this thread the next section of this reply is for extra credit: The short answer is; the float level will affect the fuel flow at high speed. The longer answer involves the design of the Carter WGD carburetor. There are two basic types of fuel metering. One involves a fix jet area relying on a variable pressure differential to vary the fuel flow, while the other design maintains a nearly constant pressure differential and varies the jet area to vary the fuel flow. The WGD, as well as the WDO & WCFB (perhaps others), feature the variable jet area design. This is accomplished by a rather large main jet and a movable metering rod. This rod has a variable diameter along its length . . . hence a variable flow area as the metering rod moves in and out of the fixed jet. Now let's look at Figure 3 in Section XII of the shop manual. Note the details of passage between the jet and the venturi. The figure depicts the state of the carburetor with the engine not running. Note the fuel level extends from the float bowl into the percolation well, and that level is the same. It is the difference between this fuel level and the discharge orifice of the main metering circuit that establishes the minimum amount of suction that the venturi must produce to transition to the main circuit, so the first potential symptom associated with a low float bowl level is a stumble/bog during that transition. So let's start the engine and open the throttle enough to develop a good amount of air flow through the venturi. The first thing that happens is the fuel is lifted out of the percolation well and exits the port at the venturi. Also note the air bleed jet at the top of the well. The design intent is that the air pressure in the upper horn is the same as the air pressure in the float bowl, so the air flow through this air jet is proportional to the difference between the venturi pressure and the air horn pressure. The actual pressure within the percolation well would be the intermediate pressure in a flowing system featuring two jets in series. Recognize that the percolation well fuel level may drop below the jet and the total fuel flow would be dictated by the area of the jet and the height of the fuel above the jet. The amount the well is emptied is controlled by the air bleed geometry. I suspect the level drops as low as the 'top' of the metering jet, but that detail is not important in understanding that full venturi vacuum is NOT applied to the fuel jet. The fuel flow is controlled by the variable area of the jet and the difference in the fuel level between the float bowl and the percolation well. A low float level directly influences the amount of 'head pressure' applied to the jet/metering rod assembly. I have included two photos that were part of a presentation I gave on the Model A Ford Zenith carburetor. This carburetor features one fixed area jet, and one variable area jet. Both jets feed fuel to the center portion of the venturi. The driver actually has limited control of the area of the variable second jet and is an enrichment feature for cold weather warm-up. Photo one shows a main jet circuit that does not feature a percolation well. Note the flow going to the engine ( that would be the young lad with the soda straw ) is a solid stream of fuel. The total flow is controlled by the suction applied by the lad and the size of the straw. Photo two shows a main jet circuit that features a percolation well. Note the flow going to the engine ( again that would be the young lad with the soda straw ) is part fuel and part air. The drinking glass would be the percolation well, and the young lad pouring soda from the bottle is the jet and metering rod feature found in the Carter WGD carburetor. Finally let's consider the sensitivity of a maladjusted float level. In the simple soda straw design the amount of soda the lad receives would not be overly dependent on the amount of soda remaining in the bottle. If we assume a full throttle case where the engine vacuum, if measured in the venturi, is 5 inHg. That would be a suction of approximately 2.5 psi at the jet tip, or about 90 inches of fuel. Missing the float level by ? inch out of 90 inches total would not result in a significant reduction inflow. In the main jet design that feature a percolation well the total head of fuel at the jet is much closer to the height between the jet and the fuel level in the bowl. This would be 1-3 inches of fuel range, and missing by ? inch out of 1-3 inches is a significant change. I suspect the size of the air bleed jet at the top of the well is also quite critical. If the area of the air bleed is small the pressure inside the well is lower (more vacuum) and the system functions more like the solid soda straw model. That condition would increase the fuel flow through the jet/metering rod orifice. Install a large air bleed and the pressure in the well becomes the same as the air horn. Increasing the air bleed area tends to reduce the fuel flow by not allowing any of the venturi suction being applied to the exit of the jet . Given a handful of jets, metering rods, and air bleeds I suspect Carter could tune a basic carburetor design to a wide range of performance characteristics. At the dealership level the first modification appears to be the metering rods. dp

Posted on: 2018/8/29 18:51

|

|||

|

||||

|

Re: Rebuilt carb issues

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thank you for the info David.

I will try oiling the throttle shaft to see if that helps. I am in 70 degree weather, so I detached the arm from the throttle to the choke. It did not seem to make any difference to the failure to return to the idle stop. I pulled the plugs, and they are quite dark, showing a rich mixture, but i think this is mostly due to a lot of idle time - it seems unlikely that the carb is flooding at higher revs. I reset the mix screws with a vacuum gauge, so I think this will help. I took the carb off (again) today to re-adjust the float,as that seems to me to be the only way to adjust the fuel mixture. But at this point (I have done all the adjustments a number of times) it dialed in as close as I can make it. so i didn't monkey with it. The car still performs poorly at speed. It winds out fairly well in first, but makes more noise than power at the higher revs in second. Not a miss, just a lack of power. I haven't really gotten it to speed in third because it runs poorly enough that I don't want to take it on the highway. Reverified the timing, at 6 degrees BTD, and I verified that the the advance appears to be working upon acceleration. Vacuum gauge also showed the timing dialed in. Ha always run well at correct timing, but it does act a lot like my Plymouth flathead when the timing is off. running out of ides here.

Posted on: 2018/8/30 0:42

|

|||

|

1941 Touring Sedan

1952 250 Convertible 1932 902 Rumble seat Coupe  Who is John Galt? Who is John Galt?

|

||||

|

||||

|

Re: Rebuilt carb issues

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dav (DavidPackard), I found the difference.

Posted on: 2018/8/30 1:15

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

|

Re: Rebuilt carb issues

|

||||

|---|---|---|---|---|

|

Home away from home

|

Posted on: 2018/8/30 1:15

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

|

Re: Rebuilt carb issues

|

||||

|---|---|---|---|---|

|

Home away from home

|

Per the throttle not returning, there are only about 5 things to look at, I give the most likely first: Please note there is no need for extra throttle springs; the one at the firewall bracket is sufficient. I regularly remove extra springs from customers's cars after putting the linkage to standard condition.

Has the bracket at the firewall, driver's side, collapsed so that the vertical portion is touching the firewall? This alters the geometry and the spring will not be effective. Shove a piece of rubber behind it for a temporary fix. Mine has had a shock bushing shoved in it for about 15 years. Has the connecting link from the back of the engine been adjusted too short or bent? Has the L-shaped link that adjusts the fast idle speed been bent too long? Did you have the throttle plates off of the shaft and perhaps they are not centered up in their bores? Is the external link that works the metering rods installed right side up? It is possible to put it on the other way, but then it binds.iirc.

Posted on: 2018/8/30 7:25

|

|||

|

||||

(45.19 KB)

(45.19 KB)