|

Re: Torsion Level-another dumb-ass question

|

||||

|---|---|---|---|---|

|

Home away from home

|

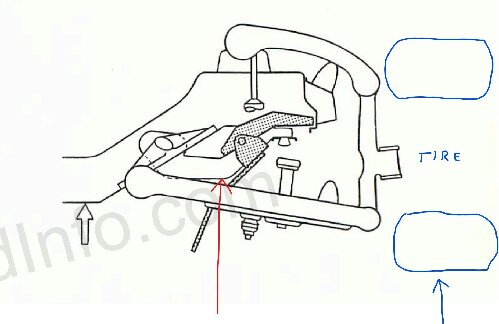

You are suggesting jacking somewhere around the red arrow? I think you will find that you will need a way to apply LEVERAGE for this idea to work. Consider that the weight of the car in that area, applied at the blue arrow, is correct to keep the suspension at the normal height. This same force at the red arrow would be much less of a moment. Understand that the torsion bars are pre-loaded upon installation to compensate for the weight of the car. Of course, it would be less force with the rear wheels lifted also, but I still don't think it would work.

Instead of a complicated jack-leverage arrangement, Packard just made this tool. You can buy a new one for $400 or if you join a local PAC club, FB group or the like, or ask your nearest mechanic with "Packard" somewhere on their website, probably you can find one to borrow. Probably even someone here willing to ship one if you ask nicely, though shipping wouldn't be too cheap on this bulky, heavy tool.

Posted on: 1/17 0:26

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

|

Re: Torsion Level-another dumb-ass question

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

You can also use a length of chain in a loop around the suspension arm to hold it up.

Use a jack under the lower A arm to lift it or add some weight in the front of the car to lower the front or a combination of both. The objective of either method is to get the load arm pushed up as much as possible. When it is in the raised position use a decent size loop of chain thru the opening in top of frame and drop down to go around the load arm. Use a bolt to fasten everything together in as tight a loop as possible. When the front end is back in normal position again the load arm will be held up by the chain and A arms will be free for any work needed. There will be a substantial amount of load on the chain so use a decent sized quality chain and bolt. Possibly someone might have a photo showing this method or saved one of Craig's old Panther site photos that they can repost. Since Craig's website is gone and there is a good chance the photos posted on the forum long ago were lost with the server upgrade a few years ago that probably would be the only way to see the procedure.

Posted on: 1/17 10:26

|

|||

|

Howard

|

||||

|

||||

|

Re: Torsion Level-another dumb-ass question

|

||||

|---|---|---|---|---|

|

Home away from home

|

This is what I came up with, as the cost plus shipping(shocking) to Canada was prohibitive. After extensive searches on this site. Credit goes to all the other folks on this site who inspired my setup. Its a pipe hangar from industrial pipe/valve supplier. 3/4" threaded rod, bent flat bar, beveled washer on top against the frame. lots of grease between top nut, washer and beveled washer. Cost was around $37 CDN. they were very kind to me. Locked the lower nut in position with a cotter key. chunk of rubber hose on the bottom bolt so as not to scar the support arm. only lifted it up high enough to release pressure. Replaced my lower A arm this way.

Posted on: 1/17 17:00

|

|||

|

1956 Packard Executive 2 door hard top (5677A)

1956 Clipper Deluxe Touring Sedan (5622)(parts car) |

||||

|

||||

|

Re: Torsion Level-another dumb-ass question

|

||||

|---|---|---|---|---|

|

Just popping in

|

I was thinking of a jack about under the bump stop after lowering the front as far as possible. I'm reluctant to buy a tool that I will never use again; although each restoration only needs the tool once I've never seen a used load arm tool for sale. Shipping is indeed prohibitive and I'm a long ways from the nearest Packard mechanic. Dads 56 has a solution that gives me the confidence to try and an idea of the strength needed. I estimate the load on the arm to be in the 3000 to 4000 lb. range and I can imagine the horror of a sudden failure!

Thanks all; I will post results if I survive the experiment.

Posted on: 1/17 22:36

|

|||

|

||||

|

Re: Torsion Level-another dumb-ass question

|

||||

|---|---|---|---|---|

|

Home away from home

|

As long as you don't cheap out on the hardware I think it would be fine. Grade 8 at least.

Posted on: 1/17 23:08

|

|||

|

'55 400. Needs aesthetic parts put back on, and electrical system sorted.

'55 Clipper Deluxe. Engine is stuck-ish. |

||||

|

||||

TL holding tool (1).JPG (4,465.92 KB)

TL holding tool (1).JPG (4,465.92 KB)