|

Re: wipers

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

FYI:

Not comprehensive and not always fully organized by part number, but I've found a quick check into the forum Parts Cross-Reference (see left side toolbar item) is often helpful. I'm not sure about the fit for your car, but here is what it turned up: https://packardinfo.com/xoops/html/modules/parts/index.php?action=search&svalue=wiper&ButtonLookup=Go

Posted on: 3/12 8:35

|

|||

|

||||

|

Re: Radio for 1936 Standard 8 installation

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Life's small victories...how dare you follow instructions and they actually work?! (I'm an engineer and we never follow the manufacturers recommended procedure).

Posted on: 3/7 18:50

|

|||

|

||||

|

Re: BigKev's 1937 115-C Convertible Coupe

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Following the older postings on brakes on this thread...

Here is a brake spring installation tech note I picked up along the way. It really properly describes spring colors, lengths and inferred stiffer on the primary (forwardmost) shoe. Attach file:  Brake Shoe Springs 101.jpg (58.81 KB) Brake Shoe Springs 101.jpg (58.81 KB)

Posted on: 3/7 10:58

|

|||

|

||||

|

Re: Radio for 1936 Standard 8 installation

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

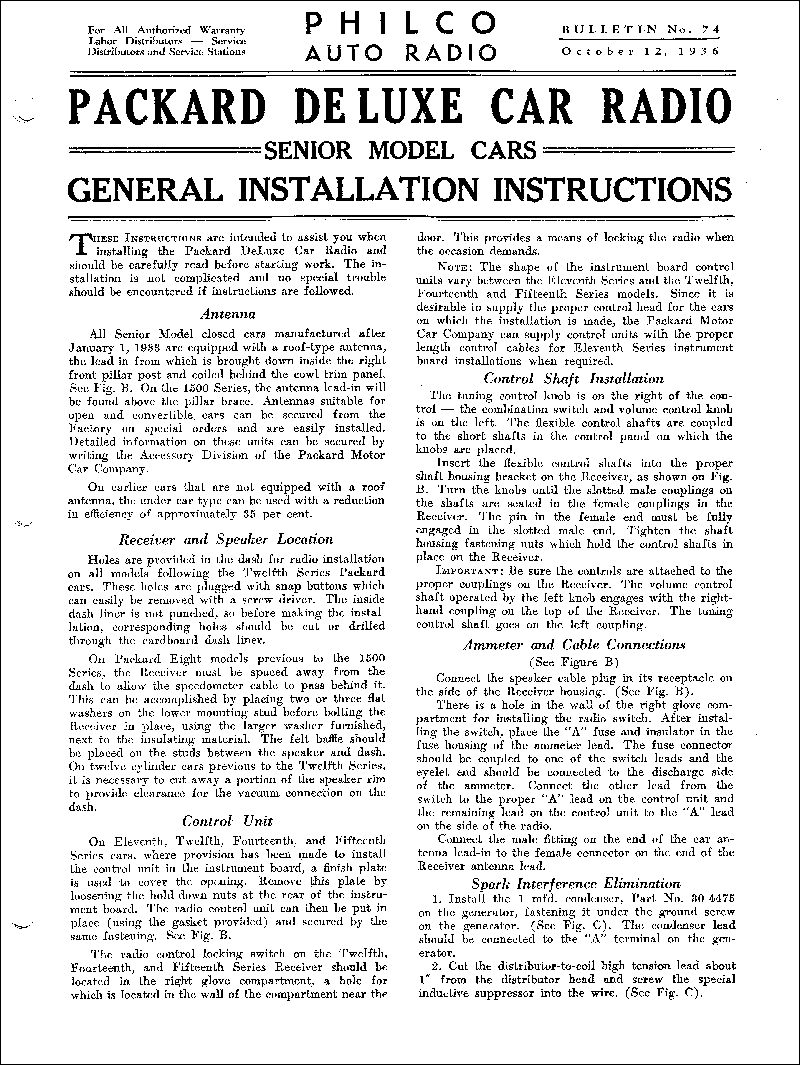

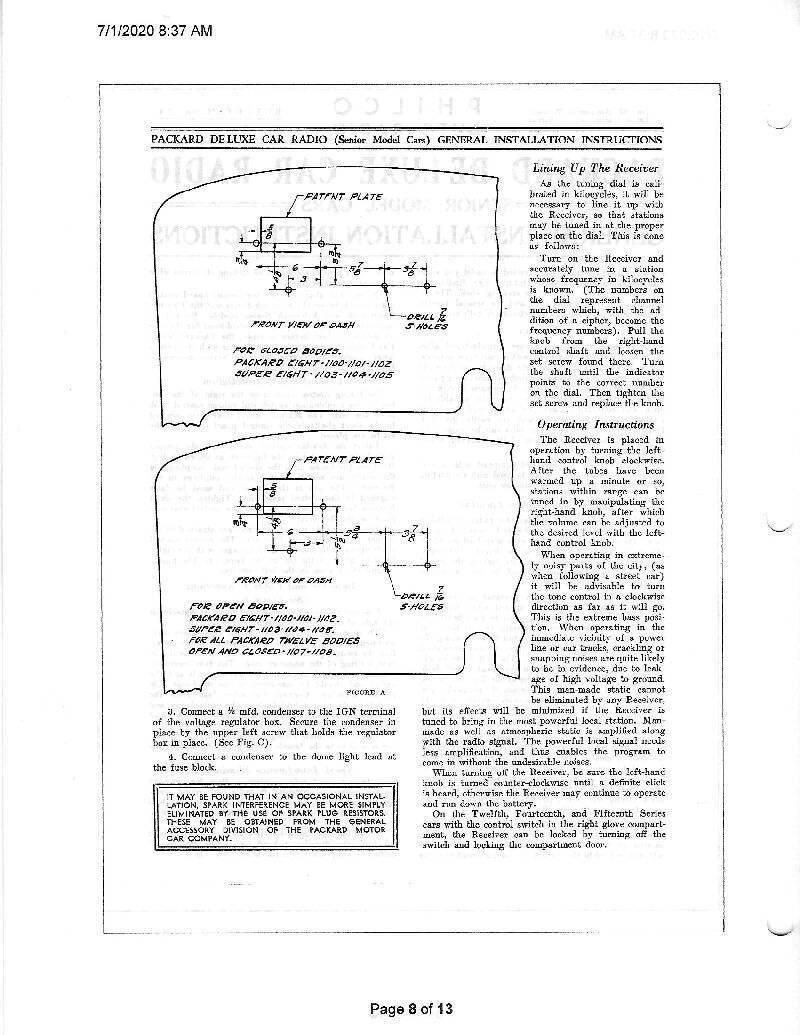

Here is the October 1936 (Probably applies to Model year 1937, but they arent different as far as I've researched) Radio Installation (for Senior Deluxe receiver box) instructions I had located. See if that helps.

Most importantly, do some image research of the same model on the internet and then link up with a compadre' who has the same year with a radio so they can take some photos/measurements in addition to the data I've provided. Dan M.

Posted on: 3/6 18:32

|

|||

|

||||

|

Re: No Compression

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I'll refer you to my brother (45 years doing Packard engine/undercarriage/restoration mechanic) as he has forgotten more Packard straight 6 & 8 valve jobs and adjustments than I'll ever learn. Private message me with your time zone/locale and an email or cell phone and he can get hold of you directly. He is going through my 37 twelve valve rehab odyssey currently.

Dan M.

Posted on: 3/5 17:51

|

|||

|

||||

|

Re: No Compression

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Todd,

I concur with all of the prior first responders on stuck valves conclusion. Packard acknowledged in the 1930's that running for short periods of time or during storage periods, that moisture (corrosion on valve stems/guides) plus rapid carbon buildup on the same surfaces would cause stuck open valves. Sounds like your chariot had this as a pre-existing condition. This was a common occurrence, to the degree that they issued multiple guidance letters to dealers/mechanics at the time. Best lowest risk approach is: 1) try the soaking guidance recommended by the other Packardites 2) open the valve cover (recommended by one Packardite) to determine "who isnt moving" 3) If "magic" doesnt happen from the soaking/prayer services, I think the lowest cost/risk approach is to pull the head/valves; fully clean/dress up the guides/stems and seats (not too difficult on a straight 6 or 8) 4) reassemble and drive 5) follow the recommended Packard pre-storage prep/guidance. Trove of valuable service data on this topic in: https://www.ebay.com/itm/404530136408?fits=Make:Packard&itmmeta=01HR7SZ3PYZY4KBPZC0T0B4RRW&hash=item5e2fe00558:g:zQYAAOSwiKBlHEo Dan M.

Posted on: 3/5 12:28

|

|||

|

||||

|

QUESTION: V12 Sylphon Secret Recipe

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I have reviewed all of the sylphon rebuild threads here and on the AACA forums. I have the temperature (various models) and 9/16" full extension stroke Packard specs for the completed units.

However: does anyone have the "fill percentage" or "mass of working fluid" for a completely empty Sylphon bellows assembly. I have the ACS-grade (purest) methanol (per the original design) and would like to not diddle/experiment if someone has worked out the fill ratio. I saw a vague reference to "half of the bellows volume" but there was no temperature vs extension (stroke) testing thereafter...just "I'm going to see how it works in the springtime"...concerned about that guy's overfill risk. I'm an engineer and am trying to be more concise in the refill process if anyone can help...once I have the total recipe, I'll post that on the forum for future Syphonites. Thanks. Dan M.

Posted on: 3/5 12:05

|

|||

|

||||

|

Re: Gauge Rebuild/Repair - Recommendations

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I'll also check out Chris Connors for regular gages, per the post.

btw, I posted on another thread about clock repair, if you need it. I replicated it for convenience here: Talk to Jim Smith (Denver area) as he specializes in all flavors of antique and vintage automotive clocks. He has done 3 1935-37 senior clocks for me and is a solid performer and has a tiered cost structure ranging from basic cleanup runthrough (assuming no parts/issues) up through higher intensity full restoration. He does have a stable of many clocks/parts so often can deal with issues out of his shop supplies. Contact Info: 1) jim@smithsarchitects.com 2) +1 303-534-0123 3)https://mainstreetclassiccarclocks.com/ He has several finished Packard clocks for sale as well. Dan M.

Posted on: 3/5 11:48

|

|||

|

||||

|

Re: V-12 Water Pump Removal

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Private Message me and I'll email you my brother's contact info (45 years as a Packard mechanic working on my 1507 V12 engine currently)

...he may be able to facetime with you and walk you through his procedure (not foolproof)...a prayer and intervention by the gods of combustion are still in order per Flack's note...definitely get some thick long shim material (0.010-0.020 thick steel) on hand to curve/bend/push/ease into all mating surfaces to clear gunk, sealant adhesion, corrosion, etc. Also, make up some hardwood slim wood wedges (2-5 deg taper on them; make a few sets as you go...low angle ones first, replaced by higher angle ones...easy does it uniformly around the periphery) once you clear the mating surfaces, to go around (5-8 locations) the mating flange so you dont apply too much prying force in one place (which will crack the underlying aluminum casting). Dan M.

Posted on: 3/5 11:35

|

|||

|

||||

PA-439661_PA-439665_Radio.pdf

PA-439661_PA-439665_Radio.pdf 441_62d5ce49127a6.png (31.92 KB)

441_62d5ce49127a6.png (31.92 KB)