|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Hi ClassicCrusier, see you have been a member for a while, and this is your first post. Welcome!

I am no expert, I just have a 320 that I have managed to keep patched together and touring for the last four years. Addressing your question about maximum oil pressure, yes that seems very high. There is a pressure relief spring that is accessible externally and may be a bit over shimmed. I would expect to see something in the range of 50 psi hot and cruising, though not sure the exact spec. for your year engine. As for the cam follower boxes leaking, I am experiencing the same issue to a far lesser degree. Used gaskets provided by a reputable source and used no gasket sealant compound based on the highly machined surfaces and excellent clamping force afforded by the ample studs and nuts. Haven't really considered what to use for sealant next try. I am sure your blown gasket is exacerbated by the excessive oil pressure where the pressure feed passes through into the covers. As for R&R, I found that backing the valve lash adjusters all the way down and holding the lever followers up with cloths pins allowed me to remove the covers and replace the covers with no other special tools needed. I hope this helps.

Posted on: 2011/6/30 21:17

|

|||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dear Classic Cruiser:

Excessive oil pressure in your motor is not good. It can blow a hole in the crankcase. This is probably what blew the gasket out. However, I too have had bad experiences with all sorts of after market gaskets and obtain best results when using Fel-Pro stock and making my own. I even get leakage through the gasket materials in the presence of silicone sealers. For reproduction gaskets that are porous I am planning to test gasket shellac (Indian Head Permatex) because it dries hard. I don't think Packard used sealers when they built their motors. The rule of thumb for oil pressure is 10 psi per 1000 rpm. Thus, the peak RPM for the Packard Eight is around 4500 rpm so 45 psi is what you want. Packard specifies 25-55 psi at 35-45 mph. An extra 10 psi will help prevent rod bearing failure under repeated full throttle acceleration or high speed cruising (not a good idea). Good luck with your car

Posted on: 2011/6/30 22:01

|

|||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Based on long experience with essentially the same engine, I recommend you set the oil pressure relief valve to give about 50 -55 psi maximum. This may occur at cold start up and modest engine speed, or at road speed with a warm engine and proper viscosity oil. But whichever, make about 55 your max before the relief valve bleeds off pressure. Whatever pressure you get a hot idle will be a function of bearing clearances, etc. and won't be changed by resetting the relief valve anyway.

Another item that may be at risk from excessive oil pressure is the oil cooler, though the 35 and up unit was a lot more robust than the 1934 unit. I've generally used gaskets from Egge and can say I've not had any problems with oil seepage at the rocker covers. I wouldn't be reluctant to use a gasket sealer, or even a slightly thicker gasket material if you think the surfaces don't mate quite perfectly. BTW, your vehicle is an "Eight", not a "Standard Eight". Folks still tend to use the name, perhaps to differentiate from the 120 and Super Eight, but the use of "Standard" as a descriptor went out in 1932 I believe.

Posted on: 2011/6/30 22:36

|

|||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

G'day Bill,

to PackardInfo, though as Jim said".....see you have been a member for a while, and this is your first post.....". to PackardInfo, though as Jim said".....see you have been a member for a while, and this is your first post.....".See you're receiving plenty of good advice from those in the know. And I invite you to include your '35 Eight in the Packard Owners Registry here on PackardInfo.

Posted on: 2011/6/30 22:55

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

ClassicCruiser:

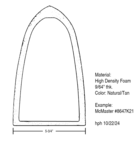

You did ask how to adjust your maximum oil pressure. Pictured below is the oil pressure relief valve assembly from my 1934, yours should be identical. Look for it on the driver's side of the engine block, at the lower edge of the aluminum crankcase casting where it meets the oil pan. There are TWO relief valves in this assembly. The vertical one with plain hex cap is the filter bypass; since the engine has full-flow filtration this is the one that must open if the filter clogs to permit the bearings to receive oil and this is NOT the one you are now concerned with. To adjust the maximum pressure, remove the nickel-plated acorn nut cover as shown. Next there is a hex jam nut which must be loosened, only 1/4 turn or so - not important how much. The threaded shaft terminates in a screwdriver slot. Unscrew (CCW) to lower pressure. You can do it with the engine running and the hand throttle set to give you max pressure and then adjust accordingly, or you can just trial-and-error it. After you've got it where you want it, tighten the jam nut and reinstall the cover. Should be that easy but if someone has buggered it in the past and you can't get a setting with the desired pressure or if the threaded rod had to be unscrewed so far the cover wouldn't fit, it might be necessary to remove the valve itself from the body casting and remove shims to lessen the spring compression.

Posted on: 2011/7/1 10:16

|

|||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Thanks so much for all the helpful response, sounds like I you should be able to handle this. I guess I'm lucky that the gasket blew, could have been metal. A couple additional questions based on the responses come to mind.

The machinist that did the engine was big on Permetex as a gasket sealer, the type that apparently stays soft, the comments here suggest this may not work well, too soft perhaps. I ordered gaskets from Max Merrit on thursday, should be here next week, what would be the perfered product to use for this, would like to hear what people think has lasted, sound like this can be a problem area in some cases. Thanks for the pic Owen, I'm attaching one of my car, it seems to be where your saying and it sounds simple enough to adjust just pull the cap, loosen the jam, and CCW till the pressure is down below 55. I suppose a person would have to wait till the car is up to temp and idleing to see what minium pressure would be.

Posted on: 2011/7/1 16:07

|

|||

|

ClassicCrusier

|

||||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I suppose a person would have to wait till the car is up to temp and idleing to see what minium pressure would be.

Correct. Depending on several factors like idle speed, type of motor oil, and temperature it can vary considerably but 3-10 psi is a reasonable range to expect. Everyone seems to have their gasket sealant favorites. On my roller shaft covers I used just plain gaskets, installed dry - no leaks or seepage. But with the experiences you've had I might consider a sealant, but definately NOT the non-hardening Permatex. There are other hardening Permatex formulas and then there's the good old standby, gasket shellac (brand name Indian Head for one, there are others). Take extra care to insure that the gasket sealant can't compromise any of the oil passages, remembering that as you tighten the shaft cover the gasket cement will be compressed and could ooze around to places you don't want it. I would say apply it sparingly if you must use it.

Posted on: 2011/7/1 17:28

|

|||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Home away from home

|

IMHO,

In addition to proper gasket/ sealer selection always check the flatness of the two matting surfaces that clamp against the gasket. The best gasket in the world is useless if the matting surfaces are not flat. I the surfaces (not including cylinder heads) are not flat within .001 to .005" I'll take a skim cut to even things up. When setting the oil pressure I usually use a quality bourbon tube mechanical or digital gauge, accurate to + - 1 to 5%, instead of relying on the dash gauge. This way you know the pressure is set correctly and you check the dash gauge for accuracy at the same time. Regards, Dave

Posted on: 2011/7/2 15:27

|

|||

|

||||

|

Re: '35 Standard 8 Oiling issue

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

I had the fella that did the machine work on the motor advise me to try a gasket fix product (he warranties his work so I tried it) that doesn't work, so now I'm down to replacing the gaskets without a doubt, so some questions.

I tried taking the valve covers off, but I am a bit intimidated about what to do next "As for R&R, I found that backing the valve lash adjusters all the way down and holding the lever followers up with cloths pins allowed me to remove the covers and replace the covers with no other special tools needed. " 1) I'm not sure what I'm doing here so please give me a clue, the term lever followers is unclear, The valve springs are pretty stout I really don't understand how a clothes pin could compress that?? 2) If I back off the adjusters that would relieve the pressure on the valves that are not being compressed by the rocker/roller, but would I not need to compress the ones being lifted to relieve the pressure on the rocker roller before removal? What tool is used to do that? I guess this is the clothes pin thing, just not sure I see how that would be done. 3) I see there are "lifters"(? not sure what to call these) that go thru from the rocker rollers and press on the very bottom of the valve, are these retained such that when the rocker roller assembly is pulled from the engine, they won't fall in to the bottom of the oil pan on the motor when it is removed from the motor? 4) finally there is the matter of how to set the valve lash once the gasket is replaced, is the a clearance with a feeler gauge etc that must be set once the gasket is exchanged? How is that set? what clearance? Thanks again for all the input Best Regards Bill

Posted on: 2011/7/6 20:02

|

|||

|

ClassicCrusier

|

||||

|

||||

(310.62 KB)

(310.62 KB)