|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Wednesday 3rd November 2010

More work on 'The Fossil' today. First was the long hinged piece that screws in at the top of the windscreen and to which the windscreen frame mounts. Needed to work out which way it goes in, finally solved by looking at the holes in both the piece and the body where it mounts. Then was freeing up the piano hinge which runs the width of the piece because it was painted with the hinge and pin in place. Some working the hinge back and forward, in sections because it very loooong, and it was OK. Then finding the 22 brass screws required, this piece had been removed by the panelbeater and not Wade. And while Wade ran a tap through 20 of the 22 holding threads in the body(the other 2 were were tap inaccessible), I cleaned up the screws. Screwed into place the piece, now with the benefit of now being held firmly by all 22 screws, swings out and back fairly easily. Next was installing a pull wire for the wire for the radio aerial. The aerial in a '34 is actually the 'chicken wire' in the roof insert and before things went too much further with the body Wade wanted a pull wire in place for when the actual wire will be installed later. First cut a wire coat hanger and straightened it. Then fed it down inside the right side A pillar, little bit of bending and jiggling required. Then attached the pull wire by first roughing up the lower end of the coat hanger and wrapping the end of the pull wire around it. Then using plastic tape, taped the pull wire and wire coat hanger together. With me gently pulling the coat hanger and Wade guiding the lower taped together end, by feel alone as there was no way to see what was going on in the bottom of the pillar. Soon met an obstacle but with "fingers" Wade moving the coat hanger a little bit one way we got it through. Progress up the pillar continued slowly and regularly until we were just about there. Then hit another snag, but under Wade's direction of bending the section of the coat hanger closest to the snag point and a little more back and forwards, it came through that too. Wade then snipped off that end of the pull wire, close to the end of the coat hanger. In order to put the coat hanger away, the end of the pull wire needed to be taken off. Thought I had would have to unravel the plastic tape, but no, all it required was a gentle tug! A lot less than I'd been using to pull it up through the A pillar! Another matter to be attended to, and which came to Wade's mind when he bumped his head against it while under The Fossil's dash, was the main cowl vent specifically the sealing rubber for it. Wade has a rubber seal from Steele's, but it doesn't fit! It's just too big, in both width and height. Fortunately with Mat's '34 handy, checked that and lo and behold, the seal there isn't fixed to the cowl itself but to the vent lid instead. What a good idea,  So it was off to Grippy Rubber where a length of 18mm X 6mm adhesive backed rubber strip was purchased for the job, and cutting and fitted instructions supplied gratis. Back at the workshop cut, trimmed and pressed the strip into place then left Wade to it. Daughter and granddaughters again, what can you do. So it was off to Grippy Rubber where a length of 18mm X 6mm adhesive backed rubber strip was purchased for the job, and cutting and fitted instructions supplied gratis. Back at the workshop cut, trimmed and pressed the strip into place then left Wade to it. Daughter and granddaughters again, what can you do.Attach file:  (28.17 KB) (28.17 KB)  (29.33 KB) (29.33 KB)  (28.51 KB) (28.51 KB)  (17.27 KB) (17.27 KB)  (32.06 KB) (32.06 KB)  (13.95 KB) (13.95 KB)  (33.62 KB) (33.62 KB)  (31.03 KB) (31.03 KB)  (31.66 KB) (31.66 KB)

Posted on: 2010/11/3 3:10

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thursday 4th November 2010

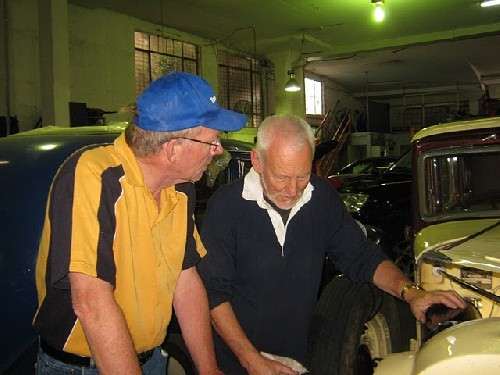

No granddaughters today, just Packards and a step up in the Packard world too, but more of that later. Yesterday Wade had continued with the cowl vent for The Fossil, installing the vent together the opening/closing mechanism in the car. Only problem was he had about four attempts to do so but couldn't get the gaps fpr the vent edge to the cowl right. The side gaps were fine but the front gap was about twice the width of the rear gap. So now that I was in attendance, standing on a plastic milkcrate for observation purposes, Wade adjusted things twice, the first of which saw little improvement while the second reversed the gap disparity. Then a third time, and it was spot on. To ensure the vent didn't move while Wade tightened everything up I then heavied the vent using my not inconsiderable weight to hold it in place, hence my use of the milkcrate, to gain a height advantage. All tightened up, then a little grease applied to the mechanism for smooth operation. Next, preparations for the body to be united with the chassis continued. The inside of the body had been used to store the side and rear glass as well as the assembled windscreen and all that needed to be relocated prior to the move. As well as that the woodgrained dash and a coupe of small panels had been accommodated on the roof, suitably protected. Wade has a couple of trolleys, one of which is stainless steel and had been used as temporary parts for the various Packards which have passed through the workshop over recent times. All it had left on it was the accelerator pedal linkage for The Fossil as well as some old wires, New spaces found for the linkage and wires, a clean up and the trolley was pressed into service. That done it was then time to adjust the positioning of the 2 by 4's presently supporting the body on top of 20 litres drums. Jacked the body up fore then aft and moved the timber and drums accordingly and as a result the body now has a wheel standing attitude with the front higher than the rear. The other side to this equation is the chassis, which also required attention prior to reunion, timing of which is expected to be Saturday afternoon when John's hoist should be free. The chassis needed to be dropped down from the jackstands under the rear axle and the ramps and blocks of wood under the front axle. Back on the workshop floor it was then time to give it a spring clean, from the firewall area back. Over the course of it sitting in this position it had picked up a covering of dust. Tried blowing it off with compressed air, but that failed, so it was back to the old proven method of rag in hand. Wasn't any more that could be done to that '34 so turned to the other '34. Never would have thought I'd ever utter a phrase like that but there it is, amazing! Not much that can be done to Mat's, until the water pump is back from machining, except remove the idler pulley setup welded to the front motor mount. Initially it was thought that this would have to be done in the '34, but closer inspection on my part, showed it was welded only to the centre retaining hub of the mount. By placing a wide, deep block of wood on the jack the front of the engine was slightly raised to 1), take the strain off the front engine mount and 2), to support the engine while the mounting hub was being relieved of the cancerous growth upon it. Then out came the hub, angle grinder readied, and that's when Barry arrived. Barry had come down from Tamworth to pick up the hot tanked aluminium heads, that right its plural, because the heads are off his '38 Twelve. He's rebuilding the engine, although it was supposedly rebuilt by a US Packard restoration specialist for the previous owner with many, many thousands of dollars of receipts for the work done. If or what was done is just a disgrace because Barry is now completely rebuilding it. Barry had one of the rods and pistons with him that came out of the engine, the one where the piston was 63 grams heavier than the other 11 pistons in the engine! And how did they address that? Not by obtaining another piston of the correct weight, or by removing the excess weight from the piston itself. Weight removal was done by grinding weight off the connecting rod instead! I believe the letters V & H, or maybe it was H & V, or was it HIV, figure prominently in the name of the restorer of Barrys '38 Twelve, but seeing that rod and piston wouldn't encourage me to use them. Another story Barry told me was about a battery hold down that had been fabricated for the Twelve. It was so shoddy Barry threw it away then later found a bill for its fabrication of $840, he now wishes he'd kept the bracket as "evidence". But enough of the venting, Barry also delivered intake and exhaust manifolds, 4 barrel carb, air cleaner, linkages and lines for Michaels '54 Convertible, all correct, one year only and almost impossible to find items. Now Michael will be able to return his '54 to the breathing system it should have. And another item was the water pump off the Twelve, for Wade to rebuild. After Barry's departure then returned to the Mat's '34's idler pulley removal. This was accomplished using an angle grinder with a cutting blade and slicing through the welds. Then cleaning up the dags with a grinding wheel, no metal was really lost in this process, as Wade tried to stay within the welds for the separation process then grind through what was left of them back to the metal of the hub. Hub then back on '34 and jack removed from under sump. Next and last was the Twelve water pump. Seeing we've had a number of water pumps over recent weeks it was interesting to see this one and how it compared to the others, a 120 and a '34 standard eight. First thing I noticed, when I put the Twelve pulley down next to the '34 pulley was the size difference. Then when Wade measured the shaft it was 20mm in diameter, more than 3/4"(19.05mm). From memory, I think the 120 is 1/2" while the '34 is 5/8". My last observation was the sheer size differential between the shaft and impeller of the 120 against those of the Twelve. After removing the bearing retainer plate, the grub screw holding the impeller, and the key for the pulley the impeller was pushed off the shaft and then the bearings and shaft pushed out of the water pump housing. The bearings were then pushed off the shaft and we made a beeline for ABC Bearings for new bearings and a modern seal. Attach file:  (19.17 KB) (19.17 KB)  (11.69 KB) (11.69 KB)  (12.89 KB) (12.89 KB)  (30.31 KB) (30.31 KB)  (38.98 KB) (38.98 KB)  (35.28 KB) (35.28 KB)  (35.47 KB) (35.47 KB)  (33.94 KB) (33.94 KB)  (40.13 KB) (40.13 KB)  (34.26 KB) (34.26 KB)  (26.63 KB) (26.63 KB)  (22.83 KB) (22.83 KB)  (35.71 KB) (35.71 KB)  (29.47 KB) (29.47 KB)  (38.00 KB) (38.00 KB)  (34.92 KB) (34.92 KB)  (33.78 KB) (33.78 KB)  (34.30 KB) (34.30 KB)  (31.10 KB) (31.10 KB)  (17.39 KB) (17.39 KB)  (25.72 KB) (25.72 KB)  (20.52 KB) (20.52 KB)  (20.92 KB) (20.92 KB)  (32.17 KB) (32.17 KB)  (15.99 KB) (15.99 KB)

Posted on: 2010/11/4 5:06

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Friday 5th November 2010

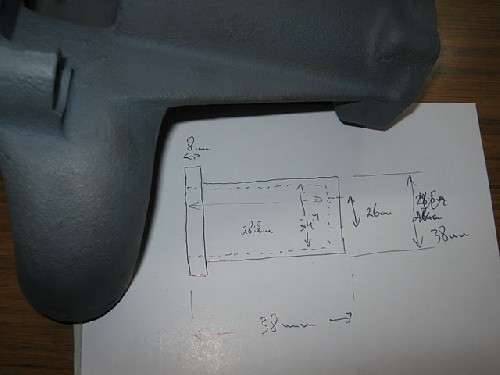

Must have spent all of 5 minutes at the workshop mid morning, dropping in to give Misty a bone and to pick up a computer from Wade. Gave me the chance to see the "engineering" drawing Wade drafted yesterday for Twelve water pump machining purposes. Then later in the morning had a call from Pepepackard, who amongst other things told me he has an old US made Allen engine analyser. Pepe, does it look like this one currently on aBay? And speaking of water pumps, received an email from Mat about the eBay water pump he bought which turned out to be for a 120, Mat also said this "....Let me know if this any use to you and I'll drop it off next time I'm down...." - very generous. Description for the pump Mat bought included "Just what your car needed! Original Water Pump Assembly (Bushing Type) replacement for 1935-37 PACKARD. With original and (mostly) complete box!"

Posted on: 2010/11/5 1:26

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Home away from home

|

Mal, has Wade considered using a Redi- or Speedy-Sleeve on the Twelve water pump shaft? Don't know if they are available in the size needed, but it is a quick and inexpensive way to restore a shaft's surface so a seal can seal. Most bearing stores here in the States can order them. They are made by National and Thompson. I used them on the rear axle outer seal surfaces on my '47. Just a suggestion.

(o[I}o)

Posted on: 2010/11/5 10:59

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Saturday 6th November 2010

The plan was that the '34's body would go on the chassis this afternoon. But......received a call from Wade just after 10:00am to say he was at the workshop and John, Rick and the guys were almost ready for the big event. Arrived there about 10:20am and the next time I looked at my watch was at 11:30am and by which time it was all over. So about an hour to move, hoist, shuffle and mate the body and chassis seems like a pretty fair effort to me. And just on that sort of thing Barry told me on Thursday that he'd recently put the body back on his '38 Twelve by himself! Took a whole day but that's the way he preferred to do it! Instead of a blow by blow description just follow the pic's in this web album. I actually used two cameras because Wade asked me to also take pic's with Gina's camera. I did that by using my camera in my right hand and Gina's in the left. So if any pic's are fuzzy blame the photographer, but I did delete the worst of them. Took 201 pic's with my camera and it would have been up there with Gina's but her battery expired getting towards the end of pushing "The Fossil" back into place in Wade's workspace.

Posted on: 2010/11/6 5:22

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Home away from home

|

G'day Mal,

"BLOODY MARVELLOUS" I've learnt more on how my car is put together with all the great pictures you've posted. Wade did look a bit apprehensive from time to time but it seemed like he had a team of bloke's with him on the body to chassis fit up. I bet Wade can't wait to get on to the next stage whatever route that might be. Please keep all the info coming as soon as you get it Mal. Regards Terry

Posted on: 2010/11/6 9:11

|

|||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Congratulations to Wade and support staff on this milestone. I'm sure rejoining the body with the chassis is a celebrated occasion....keep up the good work.

DAF

Posted on: 2010/11/6 10:20

|

|||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Monday 8th November 2010

With the workshop now able to accommodate another Packard a queue is forming at the door. However before they could be attended to Old Blue, to use a horse racing term, pulled up lame yesterday and requires urgent attention. Yesterday was a PACA run to Kurrajong Heights in the foothills of the Blue Mountains west of Sydney. 7 Packards and 1 Studebaker attended an open garden day at a house owned by a contributor to an Australian car magazine. This guy has an Austin Healey 100/4 as well as a restoration project Healey Saloon, apparently the only one of it's type left in the world. So besides the gardens there was also the added attraction of cars. Anyway going over the top of the last steep section up to this guys house strange noises started to emanate from Old Blues diff. Scared the living daylights out of Gina who, as usual, was riding in style in the back seat when the noises started. After the open garden, we then continued a little further up the mountains and had lunch at the Kurrajong Heights Hotel. From there Chris(Starliner) and I followed Old Blue most of the way back to the workshop in case assistance was required. Fortunately it wasn't, and Wade and Gina made it there safely changing over to Big Red for the remainder of the trip home. So first up in the workshop was getting Old Blue out of Big Red's parking spot then backing Old Blue into the space next to The Fossil. Still leaves a vacant space and I believe the TJ Richards bodied '39 Six will probably fill that on Thursday. But back to Old Blue, hubcaps off, lugbolts loosened, jack under diff, jackstands under axle, tailshaft disconnected, flexible brake line clamped, brake drums off, clean up of brakes and backing plates, removal of same, axles removed, diff centre loosened and then removed. Well that's the sequence of events to remove the Pumpkin from the car and it went pretty well, Used the puller on the brake drums with the right side requiring much more effort than the left which came off easily. Removing the pumpkin also had it's share of minor problems plus I didn't realise until today that Old Blue had the older style pumpkin which fits the diff housing at an angle. Wait, I'm wrong! Again? If I remember rightly Eric did mention some time ago his speedster diff from a Junior '37 is like that. The two problems with removing the diff were: 1) the copper washers which had spread and held on to the studs impeding the pumpkin in it's removal, and 2) The long bolt which goes through the top of the banjo into the body of the pumpkin, all the other studs go through the flange of the pumpkin and are accessible from underneath. Once this "hidden" bolt was found, which is 25/32" by the way and only time I've ever seen this size spanner and socket used, removal of the pumpkin proceeded in a much easier fashion. Pumpkin balanced nicely on the floor jack and was rolled out from under Old Blue just like that. When Wade had been disconnecting the tailshaft it was evident the pinion shaft bolt was loose, but what other damage might there be? Teeth on crown wheel, pinion and sun gears all looked OK on initial inspection but some of the bearings weren't looking or feeling as good. Clean up and marking of parts was followed by further dis-assembly. Pressing the bearings off the hemisphere and the large pinion bearing presents a whole lot of challenges without the specific tools required to do so. But with some improvisation along the way, all but one have now been removed. This gave Wade all the cups and cones he needed in order to phone ABC Bearings and set them on the search for new bearings. ABC are also looking for new wheel bearings, one of which appeared to be fine but the other definitely needed replacement. Just to be sure all will be replaced. Attach file:  (27.87 KB) (27.87 KB)  (32.24 KB) (32.24 KB)  (33.06 KB) (33.06 KB)  (32.07 KB) (32.07 KB)  (38.41 KB) (38.41 KB)  (39.00 KB) (39.00 KB)  (44.11 KB) (44.11 KB)  (42.23 KB) (42.23 KB)  (28.56 KB) (28.56 KB)  (30.64 KB) (30.64 KB)  (32.93 KB) (32.93 KB)  (28.02 KB) (28.02 KB)  (42.96 KB) (42.96 KB)  (31.19 KB) (31.19 KB)  (33.04 KB) (33.04 KB)  (44.51 KB) (44.51 KB)

Posted on: 2010/11/8 1:44

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thursday 11th November 2010

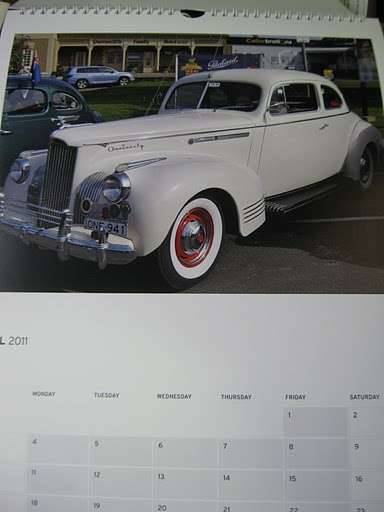

Birthday celebrations today, per the title of this song. And how did I spend the day? Why at the workshop of course, no better way to do so! First up it was into Wade's ute and off to KevinA's to pick up a '34 front axle. Now don't get excited Mat, yours is much better, see pic. Then on the way back, stopped at JohnM's to pick up the TJ Richards bodied '39 Six. Very tight driveway, with a drop on one side and house on the other, which Wade negotiated three times. Twice in moving John's Honda out, then backing it in again, and also getting the '39 out. Once out, we were off to see Stan to see how the '34's water pump machining was progressing. Trouble was it wasn't. Stan had had a stroke some months back, which Wade knew about, and Stan had said he was now OK to do "these little jobs". However the medical profession has other ideas and when Stan's wife found out about "the little job" the water pump was hidden to save Stan from himself! Now we fully understand the circumstances, another machinist is now required for any "little jobs", and we wish Stan a full and speedy recovery from this setback. Back at the workshop and, following some shuffling of cars, the '39 was backed into the vacant Packard space, jacked up and put on jackstands. John's list of requirements wasn't long but in his detailed manner it looked daunting at first sight. Boiled down to the trans - jumping out of 1st and 2nd, the tailshaft - inspect and renew the universal joints if required and remove the tow bar. Because I'd followed the '39 back to the workshop I added this to the list, fix left brake(stop) light. First job done was removing the tow bar(hitch). While I undid the bolts holding it to the rear bumper Wade was underneath separating the trailer wire plug wiring from the harness. Then Wade turned him attention to the 6 bolts holding the tow bar to the rear of the chassis. Wade also had to remove the rear muffler bracket to enable the tow bar to be slid out. Next was the brake light problem. Took off the bezels and lenses from both sides and the filaments in the globes looked to be OK. And a point here, both globes(bulbs or lamps?) have the locating pins on the same axis. The other Packard ones both Wade and I have seen are offset! But Wade said from the mess of wires underneath it was more likely that the problem lay there. First thing though was to clean up the contacts for the bulbs and, what do you know, that worked! Put the lenses and bezels back on then ran a number of tests for both tail and stop lights, all worked. Wade then went back under the '39 and cleaned up the mess as best he could. Another set of tests and we were back to scratch with the left light now back to non-working mode! Wade wriggled wires without any effect so it was into un-taping what had just been taped up. More wriggling of wires and we had contact, but it was intermittent. So a number of wires with suspect connectors were given new connectors and re-tested. Success! Taped up again and you could almost see light at the end of the tunnel, better still you could see clear and bright tail and stop lights! Then a visitor - Noel! Noel had brought over a steering wheel which Wade will take with him tomorrow. Why tomorrow? Because tomorrow, Wade and PeterL are setting forth for the Bendigo Swap Meet Australia's largest annual swap meet. Bendigo is in the State of Victoria about 500+ miles south west then from there after the swap meet they will push on to Adelaide another 400 miles west. Wade is picking up some stuff from RobT in Adelaide, so Wade is delivering the steering wheel Noel had picked on Rob's behalf on his recent US visit. Another thing Noel brought with him was a calendar. So what? It's the calendar season isn't it with Christmas coming up? Yes, but what a calendar, it has MY Packard in it! The pic's in the calender were taken by a local photographer when we had our display day on Kangaroo Island during the Rally in September. For those who'd like a copy they can be bought on-line through this link. Note, I don't receive any recompense from the sale of these calenders, just putting it "out there" for others to be able to enjoy MY Packard!  Oh, and a few others too of course, as well as a ring-in Pierce Arrow(but it is a very nice car)! Oh, and a few others too of course, as well as a ring-in Pierce Arrow(but it is a very nice car)!Later in the afternoon, that is after a delicious BBQ lunch courtesy of Rick, attention was then turned to The Fossil. Aim was to install the windscreen but before doing that a number of parts had to be installed being the brackets on which it slides out, the locks on the bottom and the rubber around the outer edge. The windscreen frame has been re-chromed so all the holes around the edge were re-tapped to remove any plating build-up. The sliding brackets and the bottom edge locks were installed then it was the turn of the rubber. This proved a somewhat frustrating experience with, it must be said, after about 1/2 hour all of 1" installed! Fortunately at this point PeterL arrived so Wade was distracted before his frustrations turned violent. Have never seen that, yet! But there have been a lot, a whole lot, of magic words as various times. Wade was happy to put the '34 windscreen aside at this point and conduct Peter through the various half done projects in the shop. Left them to getting organised for the trip. They'll be back, probably mid next week. Attach file:  (45.77 KB) (45.77 KB)  (27.48 KB) (27.48 KB)  (27.77 KB) (27.77 KB)  (40.88 KB) (40.88 KB)  (46.39 KB) (46.39 KB)  (27.14 KB) (27.14 KB)  (33.52 KB) (33.52 KB)  (35.75 KB) (35.75 KB)  (14.27 KB) (14.27 KB)  (26.81 KB) (26.81 KB)  (29.53 KB) (29.53 KB)  (19.13 KB) (19.13 KB)  (47.53 KB) (47.53 KB)  (40.42 KB) (40.42 KB)  (40.40 KB) (40.40 KB)  (43.40 KB) (43.40 KB)  (38.11 KB) (38.11 KB)  (36.02 KB) (36.02 KB)  (23.71 KB) (23.71 KB)  (25.07 KB) (25.07 KB)

Posted on: 2010/11/11 5:22

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

Register To PostTopic is Locked