|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Howard,

Yes, has happened before so Noel isn't very happy. It wasn't just stern words said to it yesterday, also some very colourful language. Hooberitz,  to PackardInfo but the link doesn't work for me. And if you own a Packard, I invite you to include it in the Packard Owners Registry here on PackardInfo. to PackardInfo but the link doesn't work for me. And if you own a Packard, I invite you to include it in the Packard Owners Registry here on PackardInfo.

Posted on: 2011/7/3 15:51

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Monday 4th July 2011

Just to backtrack to yesterday and Noel's misfortune. Noel has done a number PACA runs in the '39 without incident in the last few months and, because of that, thought his troubles were behind him. Not to be. Apparently on the way to Wilberforce yesterday a grinding noise started to come from the OD when in OD so Noel locked it out and no noise! However after leaving Wilberforce Noel tried engaging OD again, and I don't know if everything locked up immediately or sometime after engaging the OD. I do know that when it did lockup Noel was fortunate to be able to just pull off the sealed road surface as it skidded to a stop. Then came the phonecall and the cavalry, such as it was. Noel demonstrated his predicament and it was obvious he wasn't going anywhere. Chris, starliner, part of the Packard posse together with Jeff, Margaret and myself, suggested we jack up the rear end to check if it was the diff, but it wasn't. Still stuck. About this time a young guy in a Ute, Michael, pulled up and offered assistance. Michael is a Mercedes-Benz mechanic but, when the problem was explained, realised his experience didn't translate too well to trouble shooting and fixing Packards. However, with his workshop only about 200 metres back down the road, he returned there and obtained names and phone numbers of local tow truck operators. Back with the Packards the first "towie" he tried was busy, but the second wasn't and he was only "just up the road". Michael left us to await the "towies" arrival. Must mention that Michael made a terrific impression on all of us with his more than helpful and friendly manner. I'm pleased to be able to provide this link to Rivers Edge Turf where Michael works, it's the least I can do. So, any Aussies in the Sydney area, I can think of no better way of repaying Michael for his help and assistance then by using Rivers Edge Turf for any turf supplies required in your landscaping projects! Back to the tow truck. Don't really know what "just up the road" means sometimes? In outback Australia it can well mean the next property hundreds of miles away but, nearer to Sydney, I'd think it would be a whole lot closer. It was probably about a 1/2 hour wait before Jim and his Missus arrived to retrieve the recalcitrant '39. Jim is a bit of a character and as Chris said reminds him of Harvey both in physical and personality characteristics. Straight away, after the introductions, when Noel asked him about the cost of the tow he got me! Started by quoting a round-a-bout and reverse direction route. I thought maybe because a bridge we'd crossed might have had a heavy vehicle weight limit. No, he was just having some fun at our expense. That sorted out, and my heart rate returning to something approaching normal, Jim then proceeded to haul the '39 on board the tow truck. Like most tow trucks now, it is a tilt tray tow truck, or as those on the other side of the Pacific will say a roll back! The technique employed is interesting, well to me at least, because I haven't seen this done before. No, I lie, when the guy picked up a large container from out front of the workshop the same, or similar, technique was employed. At the time didn't realise it would also be employed to move disabled vehicles. Jim started by tilting the tray and sliding(rolling?) it back to intersect where the front of the front tyres contact the road. Then the tray keeps sliding back until the front wheels are aboard. This continues until the front of the rear tyres intersect with the edge of the tray. At this point, or maybe it was earlier, the winch cable is attached. Then the non turning rear tyres are forcibly dragged onto the tray, left a "skid" mark of sorts on the tray. Hard part done the '39 was then snugged down, Noel and I proceeded in the '41, playing leapfrog for a while with the truck, on the way to the workshop. We'd spoken earlier with Wade about the situation and he advised have the '39 towed in and he would open the workshop for it's arrival. We stopped on the way for, 1) Noel to be in a position to pay Jim for the tow and 2) to change cars from the '41 to my daily driver so I could drive Noel home as night was fast approaching. Jim beat us to the workshop, although we were ahead when we first stopped, and waited in the street for us to arrive. Wade was already there and had opened up and moved a couple of cars so the '39 had clear access to Packard Corner. Although it had been comparatively easy to get the '39 on board the truck the reverse applied for the unloading. Started well with gravity playing it's part but soon required assistance with Wade and I pushing the front while Noel poured water under the rear tyres to try and provide some slip. Managed to get the rear near to the edge of the tray then, using a floor jack under the centre of the diff housing, Jim moved the tray forward sufficiently that the rear tyres could be lowered to the floor. Jim then finished moving the tray forward until clear of the front tyres. Jack then went back under the centre of the diff housing and with Wade pulling and steering the jack, Noel and I provided the propulsive muscle for the '39 to take up a forlorn residence between The Fossil and Big Red. Took Noel home, through all the traffic one could muster on a Sunday evening so it seemed, with the return run a dffferent way a lot faster. Noel, I told you we should have gone the way I said! That done all that remained was to publish the mishap on PackardInfo! The previous occasions where incidents have been hushed up or talked around to avoid Noel's threats of physical violence were not going to be repeated this time. Especially seeing I was intimately involved. So Noel, there you have it, the grubby laundry aired to the world! Well, the Packard world, at least. Now, that didn't hurt too much, did it? That brings us to today, which was tame in comparison to yesterdays events. Arrived late morning to find that Wade had jacked up the '39 and it was now as high as it could be on jack stands, front and rear. If the OD has to come out, all the room possible under the car is required to provide manoeuvering space. Wade undertook some basic diagnostics and confirms the OD is definitely the culprit here. He'd also heard some "creaking" noises coming from the front end when turning and straightening the wheels, this also will be looked into. Another thing Wade noted, and you were right Noel, I was wrong  , the rear axle seals are leaking too! And to add to the list, I noticed when looking under the '39 when by the side of the road that one of the rear shock links is loose. , the rear axle seals are leaking too! And to add to the list, I noticed when looking under the '39 when by the side of the road that one of the rear shock links is loose. Enough of the '39 though, for now it was Big Red's turn for attention. Wade had been cleaning out the exhaust manifold stud holes in the block in preparation for installing the NOS manifold. I was set to work shortening both ends of the MBM studs employing a hacksaw yet again. And though I'm getting lots of practice with the hacksaw I still can't cut straight. What saved me here was that the part of the stud being cut off was being held in the jaws of the vice lined up with paint marks on the vice. With the cut starting flush against the end of the jaws I should get a straight cut, right? Right, I did, well at least straight enough for the job at hand. Studs shortened to final working length, ends ground off to remove any burrs, they were now ready for installation. Installation was the old fashioned way, using two nuts tightened against each other to provide a fixed head to use the spanner(wrench) on. Studs had also been graded for length, MBM doesn't guarantee precision engineering in every instance. Although the length differences were minor, Wade utilised the "longer" ones basically at either end of the block, although one of the "shorter" ones was also deployed there where Wade had determined one of the stud holes was a shorty. Basically after each 2 studs were tightened to the block a "trial" fit of the manifold was undertaken. At first it rattled around, some of the holes in the manifold flanges being quite large, but it still fitted without effort although more snuggley by the time the final stud was in place. While I was trimming studs Wade had turned to the bane of his life, no not Noel's '39, but oil leaks! Hates them! There's one the left side of Big Red's engine. The oil filter had been removed last week, today it was the turn of the fuel and vacuum pump. After a clean up, it looks like there's a leak from the bottom of the boss the pump mounts on. And that's where I left Wade, because I had to have some dental treatment. Last week, when I went down to finish the studs, there was a pizza surprize lunch. Well it was a surprize for me, because afterwards I swear there was a hole in a tooth approaching the size of the grand canyon! Turned out to be a little smaller than that, just a bit of tooth chipped off! Anyway, it's now all fixed. Attach file:  (33.65 KB) (33.65 KB)  (45.59 KB) (45.59 KB)  (47.08 KB) (47.08 KB)  (23.58 KB) (23.58 KB)  (43.29 KB) (43.29 KB)  (34.83 KB) (34.83 KB)  (38.90 KB) (38.90 KB)  (37.44 KB) (37.44 KB)  (39.71 KB) (39.71 KB)

Posted on: 2011/7/4 5:16

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Tuesday 5th July 2011

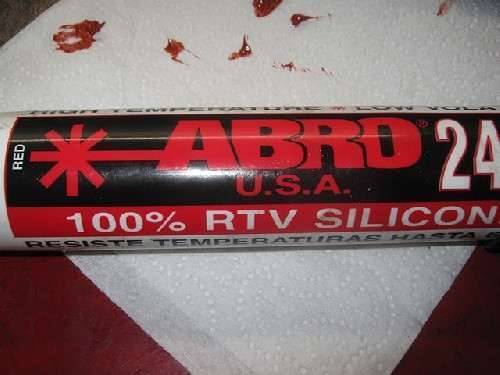

Started by removing the rear wheels and brake drums from Noel's '39. While I was doing that Wade was involved in some remedial work on Big Red's fuel/vacuum pump. This because he suspected oil could be leaking from the ends of the pump pivot pin, it's pressed in at one end and crimped, if that's the right term, at the other end to retain it. Back to that shortly after the '39 is dealt with, but in case you're getting excited Noel, don't! With the '39 up in the air, appropriately used the air gun to undo the lug bolts. But this I can tell you Noel, in order to get to the lug bolts the hub caps had to be removed and they took a bit to remove. But that just went to show our double sided tape hubcap retention system works! Hubcaps and lug bolts off next was the brake drums and for these Harvey's very handy brake drum puller came in very handy again. Hardest part, because of it's weight and the arrangement of arms and such, is getting it set up properly on the brake drum with the centre screw centered. Takes time to do it right and aligned properly but that pays off when the drums pop-off relatively easily. The right being easier than the left. Once off, the drums and the backing plates, shoes and cylinders, except for a coating of brake dust, were all dry, so no leaks. Wade now thinks the grease on the inside of the rear tyres might be because the rear wheel bearings were very well packed when replaced a little while back. With the excess being shed through the drain hole at the bottom of the retainer as it's designed to. Will know more another day because that's where things were left on the '39 to move on to Big Red. Filled Big Red's cooling system with water for a static leak test, especially at any exhaust manifold studs which intrude into the water jacket, and left it for time to take its toll. By this time Wade had fashioned a new retaining system for the fuel/vacuum pump pivot pin. As mentioned, the free end of the pin is crimped or maybe that's punched to retain it in the body of the pump. Because the pin that came out had obvious wear marks, Wade wanted to replace it, but the spare pin he had didn't have an end left to crimp or punch! Solution was to drill and tap the end of the pin for a screw, lock washer, washer, o-ring(to seal against oil leaks) combination. The other end of the pin is knurled and is a press fit into the pump body. All went together with liberal, for the size of the pin, quantities of sealer for an oil tight fit. That done, MBM gaskets were then required for the fuel/vacuum pump and for the oil filter canister to oil pipe joints. Usually Wade uses a traditional type gasket sealer but for the fuel/vacuum pump mounting gaskets he went modern and used John's Silicon sealer instead. Applied the sealer to one gasket on the bench which was then "stuck" to the insulating block and to which another gasket was "stuck" to the other side of the insulating block. Finally the outside of one of the gaskets on either side of the insulating block was Siliconed and slipped into place on the pump boss. But.......didn't I say yesterday oil leaks are the bane of Wade's Packard life? Should have included water leaks as well! Because in installing the gasket/insulating block combo he saw a water leak! A lot, a whole lot, of time and effort has been put into trying to eliminate water leaks. Each time appears successful only for another leak to make it's watery appearance! Seems like one leak is fixed only for another leak to surface, there can't be much more that needs attention, can there? After the Fuel/vacuum pump was mounted, the source of the leak was traced to the 2nd and 3rd lower mounting bolts of the water jacket side plate. All of these bolts are new and most of the bolt holes had been heli-coiled because of corrosion resulting from the holes being through to the water jacket. 2nd bolt looked perfect when taken out but the 3rd was obviously the culprit this time round. Of course we'd had to drain the water again after re-filling it only an hour or so earlier. But to clear the area of the 3rd bolt of water because of pooling in the water jacket in that area required a somewhat different approach. Water kept coming from the bolt hole long after the drain cock had stopped flowing. Wade attempted to blow it out using compressed air but that didn't work, still water. I suggested attacking it with air from the other end and Wade tried down the radiator neck with limited success. So I then suggested we blow through the heater hose with a rubber sleeve making up the difference in diameters between heater hose and air gun. Now, with the Cormorant/Pelican/Swan/Duck/?????? cap on and Mal with a thumb over the now open heater inlet pipe, a successful blow out of water was achieved. Then the bolts were re-installed. 2nd from front, no problems. 3rd from front, problem! The thread in the block was stripped! So out with the heli-coil set, tapped through the side plate into block and heli-coil inserted followed by the bolt along with liberal amounts of sealer. But, rather than refill with water straight away, it's going to be left at least overnight before being filled. By removing the heater hose and then after fixing the side plate bolts another problem was discovered. In fact removing the heater hose suited Wade who was going to do that anyway because of another leak in that vicinity. Wade thought the seal between the heater cut-off valve to the head mount was leaking. But, after taking the valve off the brass nut, the brass nut was found to be cracked! Wade was quite pleaded to be able to rustle up another brass nut from "stock" because it was the type of item he didn't think he'd have. From there the heater valve together with the new nut were installed on Big Red and the heater hose re-connected. As Wade often says, one step forward two steps back! Quote: Snapey wrote:....next time you are cutting a thread, run an expendable nut onto it first so the nut sits on the thread that is to remain. You can then use the side of the nut as a cutting guide and after you finish cutting you wind the nut off and it helps to clean the thread up. It also protects the good part of the thread from slips with the hacksaw blade or grinder. You probably already knew this, but forgot to mention it - so you can tell me to go suck eggs if that's the case! LOL I knew that, it was a long loong looong time ago, but had forgotten.  for the reminder and it'll also help others in those situations. for the reminder and it'll also help others in those situations. I'd never tell you how to suck eggs, especially with the work you're doing and documenting in your Racing Biposto Blog. Attach file:  (44.12 KB) (44.12 KB)  (42.49 KB) (42.49 KB)  (40.06 KB) (40.06 KB)  (43.16 KB) (43.16 KB)  (30.33 KB) (30.33 KB)  (34.67 KB) (34.67 KB)  (33.51 KB) (33.51 KB)  (27.95 KB) (27.95 KB)  (31.13 KB) (31.13 KB)  (24.92 KB) (24.92 KB)  (19.14 KB) (19.14 KB)  (35.93 KB) (35.93 KB)  (35.71 KB) (35.71 KB)  (23.01 KB) (23.01 KB)  (26.27 KB) (26.27 KB)  (33.99 KB) (33.99 KB)  (22.49 KB) (22.49 KB)

Posted on: 2011/7/5 3:55

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks, Howard,

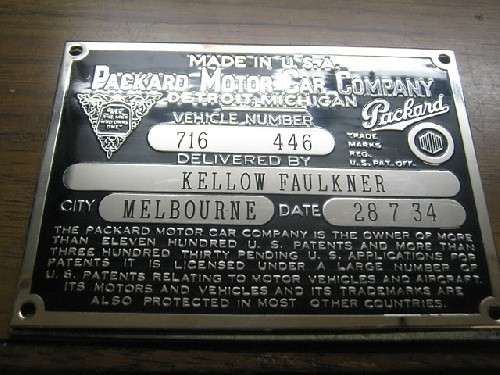

I found steelstamps.com by Argon Tool. Their "antique" font set is typewriter also like Infinity's. They will sell me a single letter I, like the Roman numeral 1, and individual numbers for $18 each. For $20 more I can have the entire antique number set, so ordered that. It's not exact, but it looks a lot more authentic than the $10 numbers. Whatever region sells those should offer to stamp them, too, and include the fasteners. Not that hard, but a hassle and expense if you just need to do one.

Posted on: 2011/7/5 18:50

|

|||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Wednesday 6th July 2011

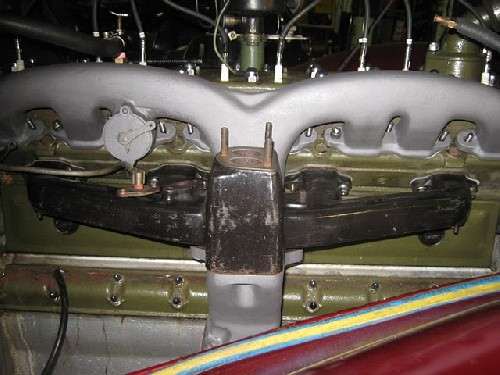

Missed the morning but, on arrival at the workshop, found that Wade had completed the left side of Big Red's engine. He'd attended a couple more water jacket cover bolts he wasn't entirely happy with. Removed them, checked the threads in the block, they were good, then cleaned, sealed and re-installed them. Filled the cooling system again, tried a pressure test and.....no leaks. Had also cleaned the oil filter housing, inserted a new spin on filter and re-installed the assembled unit using yesterdays MBM gaskets. It was now time to move to the right side of the engine and return to fitting manifolds. First Wade wanted to determine whether the NOS exhaust manifold and the intake manifold aligned at the hot box join. Using new composite manifold gaskets, metal surfaced gaskets will be used for final assembly, the exhaust manifold was secured in place. Then the intake manifold was similarly secured. Result was an even gap between the two manifolds but about twice the thickness of the copper block off plate now being used. Solution? Another copper plate, but where was the length of copper sheet the first one was cut from? Fortunately Graham was at the workshop and as always if anyone will find it, Graham will. And Did! The copper sheet had been promised to somebody but hadn't been picked up yet and was hidden away behind some boxes. Cut the rest of the end of the sheet, marked out another plate on the end piece and Graham rough cut the new plate required with an angle grinder. Then I massaged the shape on the stone grinding wheel to better approximate the shape of the present plate. Also saved the offcut from the copper sheet, there's enough there for another 2 plates if required. During my massaging Wade had received a phonecall from David at Anglade Engineering advising the '36 and '38 water pump machining had been completed. This resulted in a road trip to pick up the water pumps and also some shopping for workshop supplies. Water pumps picked up successfully then it was on to Hare & Forbes, machinery and equipment merchants, for the supplies. Only managed to source 2 items there instead of the expected 6. Then it was over the road to a large barn style hardware store, Bunnings, where 3 of the remaining items were acquired. The outstanding item apparently requires a specialist providor. But, if all else fails, Hare & Forbes did provide a lead to one if required. Back at the workshop Wade set about re-assembly of the '38 waterpump but encountered a number of setbacks in doing so. However Wade is never beaten and when I'm at the workshop tomorrow, usually get to see the grand-daughters each Thursday but apparently not tomorrow, I'm sure it'll be well under way. Attach file:  (36.96 KB) (36.96 KB)  (43.14 KB) (43.14 KB)  (38.76 KB) (38.76 KB)  (30.50 KB) (30.50 KB)  (42.01 KB) (42.01 KB)  (34.07 KB) (34.07 KB)  (37.95 KB) (37.95 KB)  (36.11 KB) (36.11 KB)  (40.53 KB) (40.53 KB)

Posted on: 2011/7/6 4:23

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Monday 11th July 2011

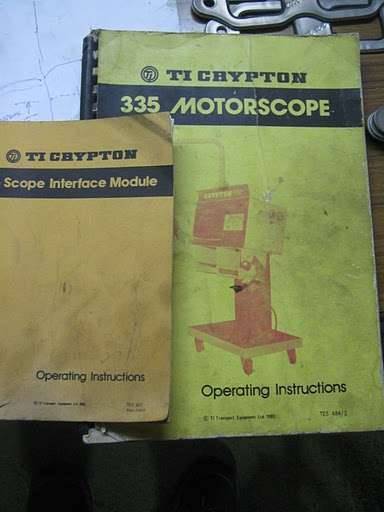

Another Packard run yesterday, this one organised at short notice but still had 5 Packards in attendance. It was American INDEPENDENTS Day, organised by a guy in the Hudson Club, and is held each year around the time of American Independence Day for cars of US automobile manufacturers other than the big 3. Biggest turn out was by the Studebaker Club, probably about 70 cars in total in attendance, see my pic's of the day in this album. Car of the day for me at least was a Railton. A what? A Railton, see this wikipedia entry. Seems to me it was the AC Cobra before there was a Cobra! I know, not US manufacture technically but there always seem to be one or two that sneak in. Besides we're all there to enjoy the cars that show up, and the Railton showed up! Harvey tells me it had a nice set of exhaust pipes but unfortunately I caught up with the car just as it was leaving for a 500 mile drive home. Today though, it was down to the workshop. With Wade arriving just before me, he drove the Ute straight into the Workshop. Wade had finished his checking and rebuilding of the Crypton diagnostic machines components. Then after unloading, it was into the Ute for a road trip. Last week Wade had overcome the problems he found in re-assembling the '38 water pump and that had been shipped to it's owner. But, when turning to the '36 water pump a problem was found with it. The sleeve Wade had machined to take a rear bearing and a ceramic seal was the wrong ID for the seal's spring mechanism. Fortunately Anglade Engineering were able to fix it on the spot so it wasn't too dramatic. Plus we were talking to the owners father who is off on a 15,000km round and across out-back Australia trip in a group of 7 off road vehicles. Should be quite a trip! On the return trip called into Graham McDonald Services, a specialist tool supplier, where Wade picked up a couple of carbide burrs. Then, because we were in the vicinity, paid Harvey a visit! Harvey was working on his "new" '40 Willys together with his mate Ross. Ross was there to lend Harvey a hand with his welding skills because the Willy's left rear mudguard(fender) required work. Next, called into ABC bearings, where Wade obtained a better copy of the seal specification sheet which led to the incorrect ID being specified for the water pump machining. Also picked up a V seal, usually used on shafts like a slinger, but going to be tested as a lid seal for the canister type oil filters used on many Packards. Have found that the rubber gasket supplied with the filters now being sourced locally leave something to be desired. So will try this seal, after trimming off the slinging lip, hopefully as a better solution. Back at the workshop found a welcoming committee of one being PACA member Wayne, wayne400, who had called in during his lunch break. Able to bring Wayne up to speed with the latest Packard news then it was onto re-assembling the components of the Crypton diagnostic machine. All together, plugged in power, switched on, and it lives! Wade has still to During the pump assembly Kevin, former Packard owner, and owner of the Daimler V12 in John's section of the workshop, arrived. Couldn't talk to John about the Daimler because John was up to his armpits in installing a transmission into a Ford Pickup. So until John was free Kevin observed the water pump re-assembly. There was a comment in there that instead of the Daimler maybe he should have bought another Packard, that way at least he could have had work on it for him! After the pump was finished, removed the trial fitted intake and exhaust manifolds from Big Red for some therapy on the NOS exhaust manifold. The exhaust manifold being in a semi-finished state had already received some attention to enable the air cleaner mounting bracket to be fitted. Now it was the turn of a number of the stud mountings because the uneven surfaces a number of these prevented the retaining nuts/bolts fitting square to the surfaces they mount against. Only four presented a problem and that's where the carbide burrs came in. In an air tool fitting they are great, allowing metal to be removed easily and cleaning up the surfaces. Left Wade washing down the right side of the engine prior to the manifolds going on tomorrow. Attach file:  (60.66 KB) (60.66 KB)  (34.77 KB) (34.77 KB)  (21.32 KB) (21.32 KB)  (45.77 KB) (45.77 KB)  (28.59 KB) (28.59 KB)  (37.32 KB) (37.32 KB)  (29.58 KB) (29.58 KB)  (37.83 KB) (37.83 KB)  (46.96 KB) (46.96 KB)  (31.82 KB) (31.82 KB)  (20.70 KB) (20.70 KB)  (25.05 KB) (25.05 KB)  (41.27 KB) (41.27 KB)  (34.49 KB) (34.49 KB)  (25.88 KB) (25.88 KB)  (39.09 KB) (39.09 KB)  (31.18 KB) (31.18 KB)  (37.14 KB) (37.14 KB)  (44.54 KB) (44.54 KB)  (42.99 KB) (42.99 KB)  (37.93 KB) (37.93 KB)  (27.55 KB) (27.55 KB)  (39.12 KB) (39.12 KB)  (38.54 KB) (38.54 KB)  (31.76 KB) (31.76 KB)  (28.46 KB) (28.46 KB)  (29.98 KB) (29.98 KB)  (28.10 KB) (28.10 KB)  (22.25 KB) (22.25 KB)

Posted on: 2011/7/11 4:56

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Tuesday 12th July 2011

Another day, and another road trip. Shortly after Wade arrived at the workshop we were off again. Earlier though, while waiting for Wade to arrive, I'd tidied up 1) the second copper hot box block off plate and, 2) the exhaust pipe flange I'd missed in cleaning up surfaces a little while ago. When Wade arrived, first thing was to box and package the '36 water pump for mailing back to southern Queensland. That done into the Ute for a trip to Ralph Moore Autoglass to pick up The Fossil's rear window which Greg had sealed into the rubber gasket. Greg had made a plywood frame into which the glass and gasket fitted for curing purposes, looks like he's done this before! Then on the return journey mailed the water pump. Back at the workshop first up was a trial fit of the glass/gasket in the rear window of The Fossil, looks good! Will require some ever so slight trimming of the side rubber, so it fits in without hassles when the time comes. Turned then to Big Red and the exhaust manifold replacement. After coating both sides of the manifold gaskets with Silcone sealant they were slid down the studs and the manifold installed. Seems there was one manifold mount we missed yesterday with the carbide burrs. Once on finger tight could get a spanner(wrench) onto the nut but couldn't turn it! Solution was to create a Special Packard Tool in the form of a ring spanner being ground down to obtain enough clearance between the nut and the manifold to be able to operate the spanner. This Special Packard Tool will henchforth be carried under Big Red's front seat in the unlikely event it's required. Hopefully, it wont! The exhaust pipe was also hooked up to the the exhaust manifold necessitating Wade to go under car to a) loosen the exhaust pipe bracket to allow for some wriggle room and. b) tighten up the exhaust flange bolts, it's easier from underneath. Seeing Wade was down below the opportunity was also taken of draining the oil, especially since the filter was replaced last week, tightening some bolts showing evidence of oil weeps, then cleaned the sump(pan). Noel, Wade tells me he has a radio box for you which Tony is going to paint, and although we haven't done anything to the '39 yet save take off the rear wheels and brake drums we'll see you at the workshop tomorrow. A little aside. There were 6 Toyota/Lexus Soarer sports cars at the workshop this morning, outnumbered Packards 2 to 1! Attach file:  (25.47 KB) (25.47 KB)  (29.63 KB) (29.63 KB)  (31.07 KB) (31.07 KB)  (29.69 KB) (29.69 KB)  (25.29 KB) (25.29 KB)  (22.57 KB) (22.57 KB)  (21.72 KB) (21.72 KB)  (46.50 KB) (46.50 KB)  (41.23 KB) (41.23 KB)  (31.30 KB) (31.30 KB)  (39.34 KB) (39.34 KB)  (34.85 KB) (34.85 KB)  (32.40 KB) (32.40 KB)  (40.85 KB) (40.85 KB)  (35.11 KB) (35.11 KB)  (36.43 KB) (36.43 KB)

Posted on: 2011/7/12 4:47

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Wednesday 13th July 2011

Spent the morning getting the intake manifold back onto Big Red. First up Wade drilled holes in the copper block off plate that replaces the hot box gasket between the manifolds. Then a trial fitting and visual inspection for alignment of the bolt holes viewed from beneath the car. Turns out the NOS exhaust manifold doesn't align exactly with the intake manifold, that's what you get when you start mixing and matching. Solution was to drill out the holes in the exhaust manifold, not by much but enough to provide a good fit for the bolts. Silicone sealant was then applied to the copper plate and it was placed on the exhaust manifold. Then using a different Silicone sealant, one resistant to fuel, the inlet manifold gaskets and the top of the copper plate were coated, the manifold installed and the fasteners tightened. Finally the carburettor, linkages, fuel and vacuum lines were installed or re-connected. Necessitated a MBM gasket for the vacuum line on top of the inlet manifold. The sump(pan) had also been filled with fresh oil, so all done Big Red was brought back to life. Running well with no water or oil leaks, but this time a fuel leak! Was leaking from the gasket around the glass bowl. That's where I left things, unfortunately missing Noel, but my cold had developed into an ear ache and I wasn't getting any better.

Posted on: 2011/7/12 23:18

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Wade's Workshop

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

...but my cold had developed into an ear ache and I wasn't getting any better. Mal, are you feeling any better or do we have to ask Wade to examine your ears using the Crypton diagnostic machine and to drill out the holes in your nose, not by much but enough to provide a good fit for the bolts of a special manifold gasket? Take care! Attach file:  (27.29 KB) (27.29 KB)

Posted on: 2011/7/16 5:39

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

Register To PostTopic is Locked