|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

DaveUK. It IS a very nice, neat and professional looking set that u have. I mite study it more if i can get over to the auto parts store and look at one of those power units to study it closer.

Posted on: 2010/10/25 10:47

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

But what is it that u don;t like about that set up u pictured above???? What I didn't like was the fact that it appears to be so large, it has to be in the trunk and makes it so glaringly obvious. While I am not a stickler for authenticity, I do want something hidden enough that at first glance the car looks proper--or at least like it was something that might have come from the factory.

Posted on: 2010/10/25 10:58

|

|||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

Which is why the in-dash version through the vent hole is still the best way to go, as long as you don't have factory a/c.

Posted on: 2010/10/25 10:59

|

|||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

Nice to see this brain pickin' BTV thread get started. Thanks packarddaveuk, and good luck in the Caspian Sea! Whoops, I mean on the Caspian Sea!

Posted on: 2010/10/26 20:36

|

|||

|

Guy

Not an Expert |

||||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

Maybe a simpler and easier way to go would be to replace the BTV unit with a conventional master cylinder. I had this done on my '55 Clipper. It has the coil and leaf spring suspension so does not have the space problems the TL cars have. The brakes work easily and the effort to use them is most acceptable. The pedal height is no problem. I believe the mechanic used a MC from a '51-54 car. There is a good supply of these parts available. The car also was converted to a manual shift 3-speed transmission at the same time. The car does not have power steering either, just a neat and simple V-8 Packard.

(o{I}o)

Posted on: 2010/11/5 10:50

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Well after several set backs I finally got around to testing my car with the manual master, remote booster set up.

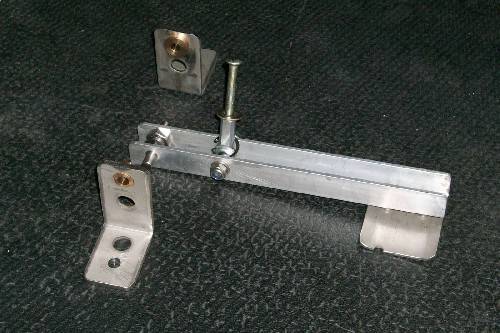

First off I tried using the original 1:1 brake pedal, this did work but there wasn't much feel to the brakes they seemed to be either on or off and although they would stop the car, required a little too much effort for my liking. I was hoping this would work but realised even with this small 5/8'' bore master cylinder I was going to require some pedal ratio to get any feel to the brakes. I decided to construct a new brake pedal based on Craig's design (thanks Craig) and now have a 3:1 ratio pedal which works fine, has feel and plenty of stopping power. I made a stand off pedal plate the same size as the original so I could use the same pedal rubber and trim. The pedal position is obviously different but doesn't take too much getting used to. I made this pedal up from scrap stuff I found at work, the brackets are stainless steel drilled with pressed in machined brass inserts, the pedal lever is 1'' aluminium channel, the pedal is 1/8'' stainless steel plate fastened to the channel with machine screws through 2 short stand off bushes made from 3/8'' stainless tubing, the pivot is machined from a 12 mm stainless bolt with the holes in the channel sides tapped out 12 mm and two cut down 12 mm nuts with Loctite applied and tightened from inside. See attached pictures. One of the snags I had ran into were the front brake shoe linings which although not too worn were cracked and flaking I suspect due to age. Replacement shoes were impossible to find here in England so the easiest thing was to have them relined with bonded linings which I got done locally and came back like new. I also tried to remove the rear brake hubs for inspection but found these to be so tight that I broke 2 different types of pullers trying to get them off the tapers so have left them for now. Does anyone have any Packard info tips for removing these things. I was reluctant to try heat for fear of damaging something inside. Well at least the car is back on the road. We attended a local annual, American/Custom/Hot Rod car show last weekend and actually won a trophy... mine being the only Packard there of any year.... I may try increasing to a ?'' bore master cylinder some time which will reduce output pressure from pedal effort but move slightly more fluid volume to maybe see if that will increase pedal feel even more but for now I am going to leave well alone and drive it when I can. Dave UK.

Posted on: 2011/6/3 11:40

|

|||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Home away from home

|

REAR DRUM REMOVAL

you say yoiu broke two types of pullers but don't sway what "types". There is a puller made specifically for pulling drums off tapered axles. You can use a blowtorchh on the hub and you can hammer the end of the puller so it puts shock on the end of the axle. It is my belief from experience as a 49 year owner/;driver of Treadle vac equiipped vehicles that they do fail. And as an owner/drive of non-power brake vehicles for 49 years including USmakes,Jaguars, Rolls and MG's that they fail also. Perhapos we all should eliminate these failures and convert the power brake cars to manual and the manual to power. PEDAL SETUP As an engineer having taken courses in Industrial Psychology and desined production line equipment nd procedures, I strongly believe that despite your saying the setup just takes a bit of getting used to, the design is dangerous in that it will increase reaction time.

Posted on: 2011/6/3 12:40

|

|||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Fred, maybe you can shed some light on my problem. I got all of the rebuild stuff for the btv from you and the work was done. but the original problem i had still exists. the brakes are almost too sensitive to drive the car. the slightest pressure will slam the brakes on. it seems like a vacuum problem. as tho there is too much. The rest of the system is in good shape, the wheel cylinders, lines, shoes and drums.

Any thoughts. JOHN MEEHAN

Posted on: 2011/6/3 13:01

|

|||

|

||||

|

Re: BTV replacement

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Hi Fred,

The pullers I broke, one was a normal flimsy 3 prong bearing type puller hooked up to a home made flange bolted on with the wheel bolts, the 3 prongs on this just bent open. Next I used a purpose made hub puller the type with 3 lugs on one side and one opposite designed for 4 or 5 bolt hubs with a square thread bolt running through pushing against the shaft, the lugs on this cast body snapped... I realize I need a hammer type with jarring action to shock the tapered hubs off as shown in the Packard service manual, my only concern being while hammering, the turning motion is surely only being stopped by the parking pawl in the twin Ultramatic, is there any chance of breaking this instead of the hubs coming loose..? I also couldn't find one of this type. The brake set up I now have installed is a manual master cylinder hooked up to a remote mounted 3:1 ratio vacuum booster mounted in the inner fender above the vacuum tank which I lowered slightly from it's original position. The brakes are still single circuit as with the BTV though all components are now new and I don't think there is as much chance of failure with the components used as with the BTV. As for pedal position, my brain is now accustomed as to where it is and I would still rely on this more than stomping down on a BTV only to find my foot on the boards some day. I wanted to use the original pedal to keep the look original but that wasn't to be so I did what I could copying someone else's design that works.

Posted on: 2011/6/3 14:48

|

|||

|

||||

(192.51 KB)

(192.51 KB)