|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Home away from home

|

I believe that 3D-printers will increase the spectrum of methods and it would be unwisely and grossly unfair to sneer at while they are in the early stages of development. It will be one of those foreseeable revolutions especially for the manufacturing branches of resin pouring technique and PVC coating.

Additional for making casting pattern, molds, visuals, samples, products made to specification, fast repair instead of delivery around the world(!), modelmaking, even batch production of casts it will be great. Perhaps I'm wrong but at the moment I don't believe that even improved printers will outstrip lines of metalworking industry or occupation groups as the computer did (for example typewriters, control systems, drawing boards, electromechanical adding-machines and their operators).

Posted on: 2011/8/5 12:31

|

|||

|

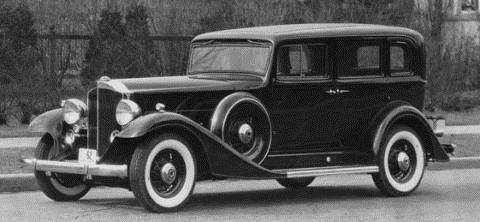

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Webmaster

|

If you search on YouTube for "printing an adjustable wrench" you will see a couple videos of an adjustable wrench being printing in one session with all internal working parts in place. The wrench comes out of the printer and the operator is then able to adjust the wrench open and closed. Pretty darn cool for prototyping.

Posted on: 2011/8/5 13:08

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Home away from home

|

This will not work for making a machined part like the trans bushing which is made out of steel backed babbit. It can be used for a cast part like a parking light bezel 48-50

Posted on: 2011/8/5 14:09

|

|||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Kevin perhaps I'm too sceptical but this adjustable wrench simultaneously makes me a bit thoughtful. The fact that the whole world print adjustable wrenches reminds me on teflon-coated frypans. My doubt was already initiated after a moment's consideration. How is it possible to scan the inner guide rails and the covered shaft end of the spiral screw? Sorry but it smells like snake oil.

University of Iowa Projet 5000 Production, South Africa Hewlett-Packard, UK  Connex Tools, USA University of the Philippines DartUp Design Services, San Diego The pictures and videos have been taken in a three-year period. If the wrench isn't a kind of reference level in a "3D-printer scene" then I don't understand why such talented innovators are so unimaginative to always scan the same object.

Posted on: 2011/8/5 15:20

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

What about the standard shift linkage bushings several have ask about help in finding a source. Apparently those either individually or in the repair kits are NLA at vendors???

Posted on: 2011/8/5 15:44

|

|||

|

Howard

|

||||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Webmaster

|

Gerd, I always wondered that as well. I think they scan the wrench and then do "clean up" on in the computer software before printing. I think the internal parts are suspended with a fine sacrificial web of material when printing, which breaks apart when they start moving the adjuster on the wrench. Hence the initial "crunch".

I've also seen instances when individual parts are scanned separately, and then assembled in the computer software, and printed as a single assembly where each part in a different color for illustration.

Posted on: 2011/8/5 15:46

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

...I think they scan the wrench and then do "clean up" on in the computer software before printing...  Additional I would like to soften the "snake oil" wording. To combine the 3D-print technology with a CAD-software but only show the scan process and the print result could rather be a kind of (bad) marketing idea. When I try to understand strengths and weaknesses of companies by studying their organization chart and business behavior then I often find the marketing department in close vicinity to the executive floor - spatial as well as emotional. Cultivated language, gorgeous girls, cashmere pullovers and before you could turn round managing director and marketing manager make a common bogeyman out of the objectiveness of the engineers. Three years later an apple-polisher will be the new principal engineer and the company goes through bad times. I classify such mistakes as structural weakness.

Posted on: 2011/8/5 16:32

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Can you make gorgeous girls in cashmere pullovers all in one printing or do you have to make the pullovers separately?

The shift linkage bushings are a machined part, the printer makes the first step in making a mold for a casting. A casting like a steering column shift lever, a driving light bracket or a cormorant wing. These items will most likely need machining after casting. If you had a big enough machine that made the actual part and it could make it in different materials, heck, you could make a '42 Darrin Convertible Sedan!!

Posted on: 2011/8/5 21:06

|

|||

|

||||

|

Re: Now if this could be used to make Packard parts

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I am not talking about the printer here. I was referring to the front end-- a professional version 3D scanner and software that outputs a CAD/CAM program the printer utilizes. I would think that would be a standard program that depending on need, could be configured differently. Send something to a mill, laser or water jet or in this case, to a lathe to make the bushings instead of a printer. Even fairly inexpensive home kit setups such as this onehttp://www.camtronics-cnc.com/index.asp with low end software output standard files. If so, what I was thinking was those files should be able to be sent to a shop who might be a little slow right now and have spare machine time & would be willing to do small runs. If not a standard file, there are probably conversion programs that can change format. Would think eliminating the hours needed to draw the CAD program or even blueprints for a bushing or any other simple part from scratch should reduce the upfront cost considerably.

Anyway, this discussion has gotten off track and makes me no nevermind. Just trying to throw out an idea which I think could stand investigating. If Leno's setup can make part of the process cheaper and easier, there should be other ways to take advantage of the technology.

Posted on: 2011/8/5 21:49

|

|||

|

Howard

|

||||

|

||||