|

Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

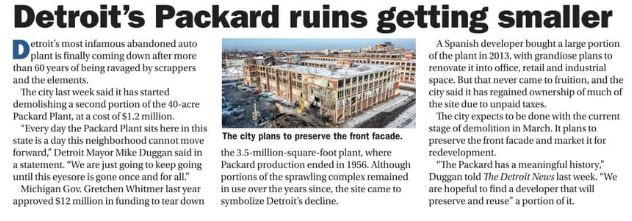

My nephew sent me this update on the Packard Plant.

Bob Attach file:  Screenshot_20230219_070007.png (161.20 KB) Screenshot_20230219_070007.png (161.20 KB)

Posted on: 2023/2/19 8:01

|

|||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

My guess is it didn't cost that much to build as tear down now.

Posted on: 2023/2/19 11:49

|

|||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Just popping in

|

Quote:

No doubt. $12m to tear it down seems crazy.

Posted on: 2023/2/25 13:42

|

|||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

Agree…Journalism bares little relationship with what it was a generation or so ago. Ernie in Arizona

Posted on: 2023/2/25 15:12

|

|||

|

Caretaker of the 1949-288 Deluxe Touring Sedan

'Miss Prudence' and the 1931 Model A Ford Tudor 'Miss Princess'

|

||||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

This is just a question for the experts:

I had always figured that, while final assembly was moved to the Conner Avenue plant, and engine and axle assembly had been moved to the Utica plant, that some smaller components would have been continued to have been manufactured in a portion of the East Grand complex, where they had presumably had been for some time. Given the space issues they had at Conner Avenue, it would think they would have tried to maximize space there by keeping what production they could at East Grand? Maybe not.

Posted on: 2023/2/25 20:06

|

|||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

Prior to the 1955 models, Packard made their own transmissions and rear axle assemblies. Starting the the V8s they used these components from others.

Posted on: 2023/2/26 13:40

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Not really true. First of all, Utica was engine and transmissions. Some other pieces were also made there. A significant part of the East Grand Blvd. plant was occupied with body transport, body storage and component storage. This took up a lot of imagined free space. Plus Briggs was actually renting additional space in the plant. AND there were always trucks coming and going to and from Briggs over on Conner. With production relocated to Conner... all this became unnecessary. As for Conner Avenue there were some space issues, but many of those "issues" were just as much organizational as spatial. It is also a pity that the modern method that Packard was attempting to do at Conner has been so bitterly criticized. But when the Japanese used this same process years later in their plants they were hailed as geniuses! The production process is known as "Just In Time" or "J.I.T." In J.I.T. a part or component or subassembly is delivered to the factory just in time for it to be assembled on a vehicle. This way requires far less handling and storage space to be allotted for keeping such items on hand. In this process, it is the vendor who needs to be at the top of their game. And some weren't. This got blamed on Packard. But those anxious to criticize Packard or J.J. Nance for imagined inept thinking jumped all over what Packard was attempting to do at the time. Of course the industry in the USA was (as a whole) not fully embracing J.I.T. at the time. And there were obviously numerous teething problems and adjustments that resulted from the move to Conner. But the issues were/are not nearly as cut and dried as most critics and critiques imagine.

Posted on: 2023/2/26 22:03

|

|||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

JIT depends on reliable delivery of parts... coordinating production schedules within the factory, or with neighboring factories, to minimize stored product and stagnant money.

But if you can't reliably get stuff then you shouldn't JIT that part. Part of the reason the COVID supply shortages hit so hard is because companies would JIT literally all the way across the globe, but when shipping slowed, then they had no stock. In other words, JIT is more than "stock less stuff", it takes careful planning and a lot of inside knowledge on the production processes to not screw yourself with unexpected problems.

Posted on: 2023/2/27 10:47

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: Packard Plant update....

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Yes... these things are all obvious today– especially in hindsight which is always 20/20. And the fact that modern car manufacturers now have the process pretty much down cold. Yes... Packard depended (perhaps naively) on vendors to do what they had indeed promised they could do. Yes... vendors dumped Packard in the grease. And one can blame Packard and J.J. Nance (and a lot of others) and the blame-game is a mainstay in American thinking– no matter the field. Yes... I am very familiar with J.I.T. and how it works, having been involved in this very process during most of my adult career on the auto industry. But the issue I was attempting to illuminate is that no critic or critique has pointed out that Packard was attempting to do this long before the Japanese. Despite the Japanese being credited today with somehow inventing J.I.T. This was a pioneering move ahead of its time– whether it worked or not For Packard. And whether it has been recognized or not. Even up until its end, Packard was an amazing, forward-thinking company and I still give them an "A" for effort– in spite of what took place at the end and at Conner Avenue.

Posted on: 2023/2/27 12:50

|

|||

|

||||