|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Aren't those nuts suppose to be brass?

And we are talking nuts here not bolts as posted. Just asking. Wes

Posted on: 2013/3/2 16:20

|

|||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

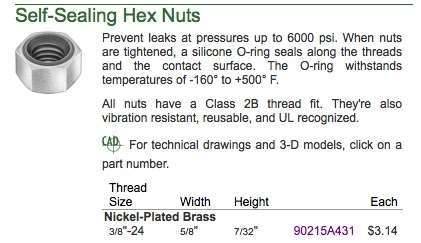

McMaster has a brass sealing nut with a silicone O ring good to 500 degrees. While not a locknut it has antivibration properties. No idea if the stud temp would exceed the max but maybe worth a look. Even if the O ring didn't last, it should be no worse than plain brass.

Attach file:  (24.40 KB) (24.40 KB)

Posted on: 2013/3/2 19:16

|

|||

|

Howard

|

||||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think there must be something else going on with David's manifold fasteners (nuts and studs, not bolts) as having them come continuously loosen just isn't a problem that one encounters. Perhaps the threads on the studs have deteriorated?

Posted on: 2013/3/2 23:18

|

|||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi all, Brass is good..I would recommend new brass manifold nuts.....My 66 Rolls-Royce wheel nuts are brass and torqued to 45 ft lbs. The principle of the Packard Exhaust manifold is no different....You must have sufficient manifold tension to seal the manifold, but must allow the exhaust manifold to "slip" across the face of the gasket as it expands. I have quite often observed my Packard exhaust manifolds glowing in the dark after a 65 mph run. The brass nuts are designed for this use as they expand more than the stud when heated and grip the steel studs in the block. This discourages their migration during use. I have tried to "second-guess" Packard some times and it usually ends badly. I recommend that you use the brass nuts and the 25-30 ft Lbs torque recommendation. (use 25). DO NOT overtighten as a tight manifold will tear the gasket apart. Be very cautious also of refacing manifolds as this is usually done by milling and the resultant milling marks will grip and kill the gaskets. Best regards Peter Toet .

Posted on: 2013/3/3 3:51

|

|||

|

I like people, Packards and old motorbikes

|

||||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just took a look so am coming in late.

Studebaker and Chrysler products of this immediate postwar era used brass nuts--and they are quite good for the reasons noted. Packard, however did not. They used 3/8-24 extra heavy series steel nuts. The "extra heavy" means that they had an 11/16 hex instead of the 9/16 that is standard for 3/8 threads. This in concert with the extra heavy series flatwashers under them gave much better support as the washers need to span between adjacent ears on the intake and exhaust manifolds. Will have to look and see if McMaster has these. I've never had any trouble with them coming loose, and there is no need for any locking washers. A sure sign that an engine has been worked on when you go to look at a car is that the washers under the head nuts will be missing, and there will be small nuts holding down the manifolds. Peter is quite right about the finish on the manifold: Best if it is smooth as a baby's backside, and with a small chamfer around the edge. A right angle die grinder with a roloc disk does that fast and easy.

Posted on: 2013/3/3 6:08

|

|||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Us not having a problem is not the issue. The issue here is how to help David.

Heavy hex nuts should be available, but those washers are a little tougher. Both can be made from stock by a machinist. Maybe those fasteners are some cheap grade of imported junk. There are many different alloys of brass and I have been burned by parts made from substandard materials. I actually never had a problem with those manifolds even when all the original stuff was long gone. They aren't supposed to require a lot of torque and small pattern nuts actually stress the studs less than the large ones. Anyway, why not start fresh and buy some known good hardware. If the problem persists then pull the manifold and have it checked.

Posted on: 2013/3/3 9:40

|

|||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Extra thick flat washers may not be a problem to source; though not for this specific application I've bought them in aircraft quality grade a few times in various sizes from MSC Inudstrial Supply. However you may have to purchase a box of 50 or 100 but still far cheaper than having them made.

http://www1.mscdirect.com

Posted on: 2013/3/3 9:50

|

|||

|

||||

|

Re: loose manifold bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Sure stirred up a bunch of interest on this one. I have a spare 288 50 engine in the garage. I'll steal the washers of it that one for now, and reinstall the existing nuts (they are the larger version) and see what happens. The comment on the smaller 9/16" nut is interesting, since that's what is on my 39 120 engine.

Thanks for all of the input from everyone.

Posted on: 2013/3/3 14:02

|

|||

|

||||