|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Howard - see the post still active " 1936 Packard 120 horn button assembly"

atpackardinfo.com/xoops/html/modules/newbb ... um=1&post_id=181173#forumpost181173 this has details drawings of the steering wheel/horn ring, as well as the electrical schematic, as usual, HH56 is all over this... DAF

Posted on: 2016/8/30 15:20

|

|||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

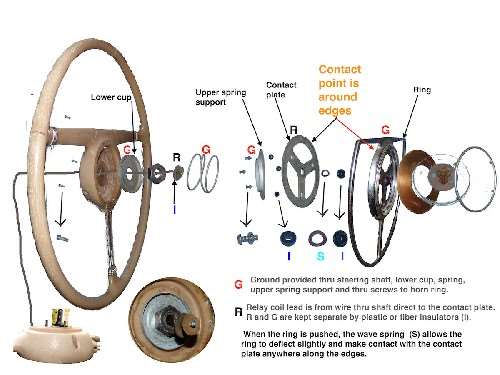

Just to confirm -- the wire you short to make it work is the wire coming out of the steering column at the top where the horn ring goes??? If not, where are you shorting to have it work? Assuming that grounding the wire at the wheel is what makes it work there are a couple of possibilities in the wheel for the horn not working. The wire has to make good contact with the center of the contact plate and the edge of the contact plate and also the bottom outer edge of the ring has to be clean and not oxidized so they can make good contact. I took the liberty of borrowing Wes's excellent exploded diagram of the 47 wheel to illustrate the electrical path. Note that I did not think in time to look up the pieces in the parts manual to use Packard names but rather gave them my own names. Ground path is via the items labeled G and the wire to relay coil is via R Ground is provided by the steering shaft. It goes thru the cup and spring to the upper spring support then thru the 3 screws to ultimately reach the ring. The wire from the horn relay coil goes thru the shaft and the cupped portion at the end of the wire makes contact with the center of contact plate. The plastic insulators keep everything separate. When the ring is pushed the wave washer allows a slight deflection so that the bottom edge around the circumference of the horn ring will make contact with the outer edge of the contact plate to complete the circuit. One reason for problems is if the edges of the contact plate or horn ring are dirty, oxidized or corroded and the contact is poor. Another is if for some reason the wheel is too high and the brass convex cup at the end of the wire cannot reach the contact plate. When I went to figure out the electrical path I found mine was not working very well. Took it apart and wire brushed the contact plate and the bottom of horn ring around the outer edge. When it was back together, all was well with good contact made when pushing anywhere on the ring. This description was for the 47 wheel. I suspect it is the same from 41-54 but have no other wheels to verify that belief.

Posted on: 2016/8/30 16:14

|

|||

|

Howard

|

||||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hello Yes the wire iam shorting across is the wire in the column. I am now going down the shop so are check to make sure all contacts are clean. when this as all put back togeather how much play should there be for the chrome horn push to push. is it a case of it being quite tight mine has a paper gasket between the steering boss and the horn centre that the chrome horn push is part of. Thanks Howard

Posted on: 2016/8/31 0:06

|

|||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Home away from home

|

Well I had another go this morning and its the oposite problem now the horn keeps going off or when you turn the wheel it goes off. Ive checked the wire and there are no bad areas on the cable.is the horn switch adjustable. Thanks Howard

Posted on: 2016/8/31 6:01

|

|||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Home away from home

|

Assuming the plastic insulators are in good shape, could there be a bare spot in the wire as it goes down the tube? A short there would make the horn turn on.

Posted on: 2016/8/31 9:34

|

|||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Thanks for mentioning the paper gasket. Not sure how yours is positioned but I had forgotten it was required on some wheels and since I am transferring my old ring to a new deluxe wheel I need to make one for mine.

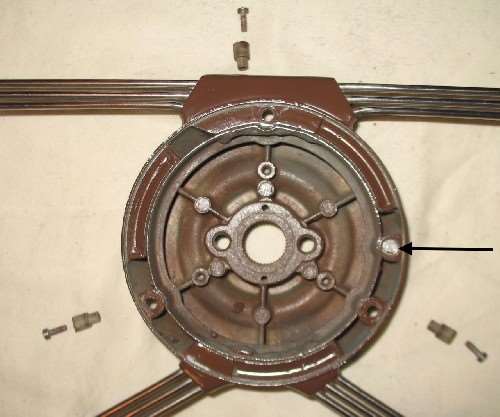

The stock wheel has a plastic or hard rubber hub with only the center portion where the shaft is fastened being metal. As Wes's drawing shows, nothing extra is required on those wheels. The deluxe wheels -- at least the K wheel -- has a metal hub and I wouldn't be surprised if others have a metal hub too. I know you posted a photo of your wheel and think it was a K but don't remember for sure. If your hub is metal there are some places to check for possible shorts. The three screws holding the ring to the hub have plastic insulators in the holes. Make sure those insulators are good. I notice one of mine has a section broken out on one side which could allow the screw head to touch metal under some conditions. That would cause the horn to blow. There should be a thin fiber or paper gasket between what I call the contact plate on the ring and the hub to prevent direct contact with the hub. Also, there is a locating pin on the contact plate and a corresponding depression in the hub (arrows) which keeps the ring from rotating. There needs to be some kind of insulator in the depression so the ring cannot rotate and have the pin touch the sides or bottom of the depression. It could be plastic or perhaps the paper gasket was formed with a shallow pocket around the pin to fit in the depression. The deflection is not very much on my ring. I don't have a convenient way to measure the amount but it is determined by the wave washer spring and plastic insulator in the center. If you feel yours is too little possibly adding a thin gasket like a layer or two of paper in the rounded metal pocket between the black plastic insulator in the middle and the metal and also under the 3 black insulators would raise the contact plate a tiny bit and provide more clearance. You would not want to add much because that could increase the strain on the plastic and cause it to crack or deform the wire contact piece if it gets too tight.

Posted on: 2016/8/31 10:31

|

|||

|

Howard

|

||||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Home away from home

|

I dont have a K wheel now I have fitted a 3 spoke wheel, The 3 screws that hold the chrome horn push to the main wheel do these have to be really tight or slack, if they are tight i take it you dont need to push on the chrome horn push a lot to sound the horn. Howard

Posted on: 2016/8/31 12:12

|

|||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The screws should be snug but with the plastic hub not terribly tight. There should be no rotational play other than the tiny bit that might be allowed with the pin and depression. My ring deflects very little. If I had to take a guess I would say the distance between the contact plate and where it contacts the ring edge is in the order of less than 1mm. That height is determined by the plastic insulator and wave washer in the middle and the length of the 3 black insulator washers holding the contact plate onto the ring. If yours is too close you might try a couple of layers of copy paper under those points and see what happens.

With no metal hub, as Marston mentioned earlier the problem is more likely to be with the wire or possibly that fiber insulator under the end contact. Less likely would be the contact plate is loose or warped. Since it happens when you turn the wheel I would say check the wire first. Where it comes out thru the end of the steering box in the engine compartment is a very vulnerable spot. Heat and grease can cause the insulation on the wire to fail right at the small hole where it exits the box. Turning the wheel and twisting the wire could be just enough to make a bare spot touch the box.

Posted on: 2016/8/31 12:52

|

|||

|

Howard

|

||||

|

||||

|

Re: Steering wheel horn push

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have checked the wire and there are no bad spots on the wire, i mat try what you said with paper. Are let you know how I get on.Heres some pics of the parts

Howard

Posted on: 2016/8/31 13:48

|

|||

|

||||

(104.99 KB)

(104.99 KB)