|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

Did you check the lifter-valve stem clearance? 0,030 to 0.070 using a special gague, or the gauge can be made by removing the spring from a lifter. Possible that one or more lifters is tight after the valve seats were ground.

The lifters can be tested. Look at the YouTube video from Speedwell garage. Speedwell Garage testing hydraulic lifters I have a copy of this tester and could mail it to you for the cost Ross charged me for making it, $220. But it may take a little while for me to get it packaged up and mailed. Or you could contact Ross himself. These lifter plungers are the same as used on the other 1951-54 engines. New reproduction lifters are available from Kanter and Max Merrit. New reproduction lifters can be obtained from Kanter and Max. Max also sells the gauge, or it can be obtained from Pacific Northwest Packard club. Note Max sells two different lifter gouges, one they say is for NOS and one for their reproduction lifters.

Posted on: 2023/7/2 9:19

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I would recommend looking thru the service bulletins as there are a few mentioning causes and corrections for noisy tappets. You can select the service index on the left and then choose 51-4 and engines to find them. You didn't mention how long the engine was running in total but some have reported it took a fair amount of time to get all the air out of a freshly rebuilt engine before their lifters quietened

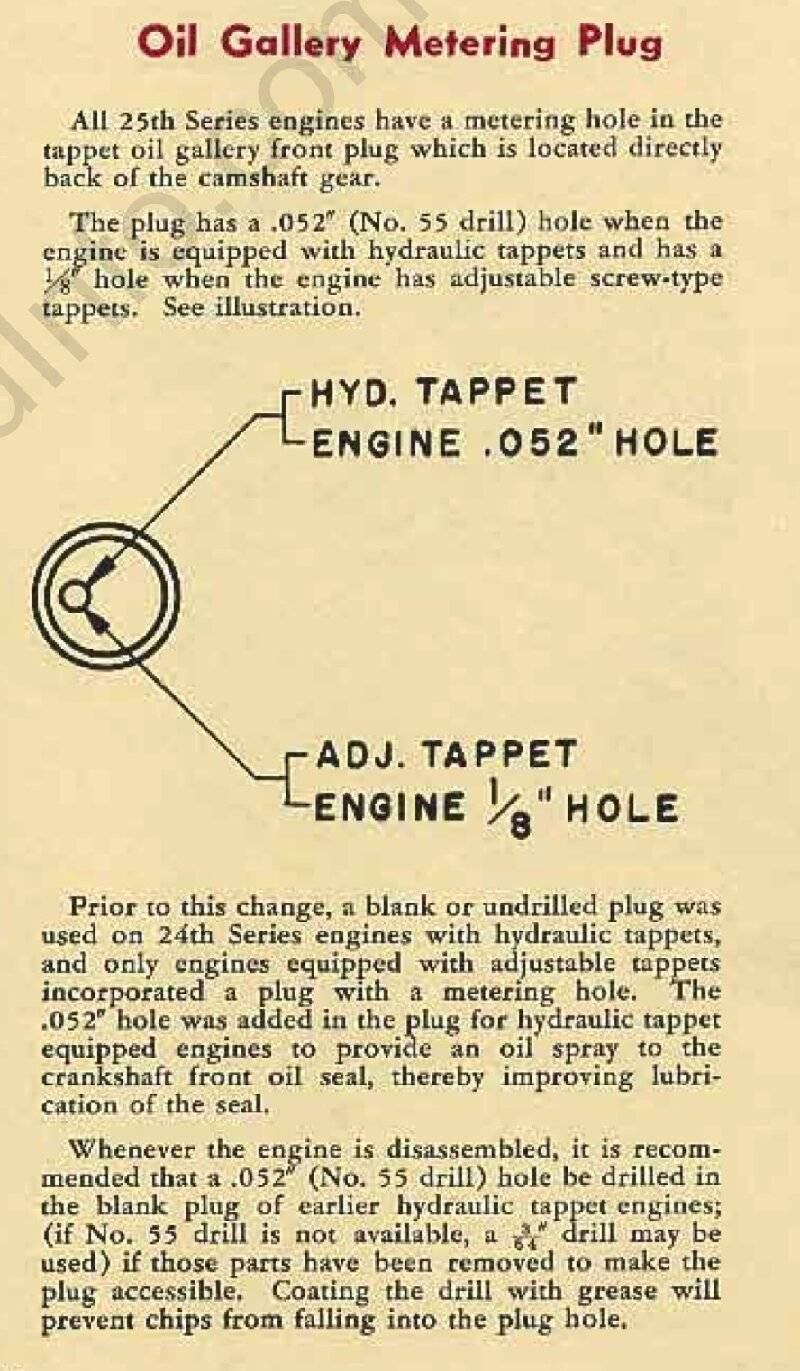

If it ran a decent amount of time and still noisy, I would also check the lifter supply pressure as per one of the bulletins. A restriction in the pigtail tube or one of the fittings could be lowering the pressure. You did mention changing the front plug. The orifice for hydraulic lifter cars has a specific opening Packard wanted so if larger, that could be bleeding off too much pressure. IIRC, a bulletin on another subject casually mentioned another function of the orifice was to provide a more rapid bleed out of air which might get trapped in the lifter gallery. If there is no opening it is possible any air bubbles in the oil could be collecting and affecting the lifter supply.

Posted on: 2023/7/2 10:53

|

|||

|

Howard

|

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

I've got to double check my notes on the clearances of the valves, I'm suspecting faulty lifters.

I might take you up on the tool - will call speedwell tomorrow morning and let you know. Howard, you might be on to something, I did look at the old donor block and the plug does have the hole mentioned in the bulletin at 12 o'clock position. I might drill the hole in the pipe plug as well Thank you.

Posted on: 2023/7/2 13:53

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

Did everyone miss that he has 20w50 oil in it? I run that in my Harley-Davidsons, fer cryin' out loud. Drain that sludge out, put some 10W30 back in it and try it again. The only time I'd use 20/50 in anything would be if it calls for it - this doesn't - or if I have clearances I can measure with a carpenter's measuring tape. Since the engine is brand new (I know, a fresh rebuild), I suspect it's not flowing the thick oil properly at temperature.

Posted on: 2023/7/2 17:14

|

|||

|

If you're not having fun, maybe it's your own damned fault.

|

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

Eric, heed Wat. Why are you running molasses in your engine? A friend w/ a 292-ci Zephyr V-12, which of course has hydraulic lifters, decried their noise.

I talked w/ a pair of lifelong Zephyr guys who on hearing his lament, shared the same first question and suggestion: "Why is he running glue (or less polite) in his engine? Tell him to change to 10W/30, add a pint of Marvel Mystery Oil, then drive the hell out of it for 30-50 miles." Meanwhile, at the risk of sounding like a broken record, enter zinc/ZDDP in the Search box here. Short story: The ZDDP scare was just that, but marketing abhors a vacuum. Just use any major brand 10W/30 and don't reinvent the wheel. Packard service departments coined a good expression: "Factory standard." 50W oil is hardly factory standard. And really, avoid any product called "Classic."

Posted on: 2023/7/2 22:34

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'd look at how much was taken off the cam, heads, and the tappets and if that's outside the adjustment.

Typically, when you take off you make something else bigger to compensate. ps: I'm not wading deep into the oil issue again: A good break in oil should be used at first. Then replaced to flush out early wear particles. People are using racing oil to get high ZDDP levels. The container "numbers" do not reflect the actual viscosity increase at temperature. In this case, more the additive package. It's more work for the pump to deliver oil so more HP loss, but not significant. May cause cranking difficulty if xtreme cold climate.

Posted on: 2023/7/3 10:57

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

ALCON;

All good info. Engine was first started with break-in oil, then drained and refilled. Earlier this morning, drained out the molasses and filled with 10/30W. Engine has been running now for thirty plus minutes and still noisy. I'm still suspect on wrong lifter plungers as I have no clue where they came from nor, a part number. I was provided with the parts. The oil pressure readings are taken from the rear main plug on the right rear and from the main supply (gauge in cluster - top is the main feed).

Posted on: 2023/7/3 11:55

|

|||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I cannot see the detail but there looks to be something else at the upper port. Is there anything between the pigtail tube end and block besides a straight 1/8 NPT to 1/4" inverted flare fitting? That port is the oil supply to the lifter gallery and should have the pressures Packard mentioned in one of the bulletins.

As Packard found out with the first implementation of hydraulic lifters and their original inline filter plumbing design, if anything is restricting flow in either pressure or volume to the lifters they can become noisy. The pigtail tube was then retrofitted to ensure a high pressure full volume supply to the lifters. Oil thru the pigtail comes via a port fed directly from the oil pump.

Posted on: 2023/7/3 12:10

|

|||

|

Howard

|

||||

|

||||

|

Re: 359 Noisy Lifters

|

||||

|---|---|---|---|---|

|

Webmaster

|

I'd also ensured you have the restrictor in the feed to the oil filter. It was there to force the bulk of the oil to the lifters rather than the filter.

Posted on: 2023/7/3 13:10

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

plug.jpg (163.90 KB)

plug.jpg (163.90 KB)