|

MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

I'm starting this thread for my 1955 Panama. We've determined the engine was swapped out of a 1956 Constellation at some point.

Per the forum below: The charging system has been swapped to a negative ground. Charging system works just fine. I'm wondering if there's anything else I need to check to ensure all my electrical will work properly. Things I know that don't work: Gas gauge reads backwards and the cluster lights don't turn on with the headlights. packardinfo.com/xoops/html/modules/newbb/viewforum.php?forum=10

Posted on: 2023/7/13 12:17

|

|||

|

||||

|

Re: MikeSC

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

As long as there are no modern solid state replacement devices such as a radio vibrator or torsion level switch or a modern permanent magnet starter or window motor installed then nothing else on a Clipper will be damaged or really care about the polarity swap. There is still a question about what exactly is different in voltage regulators to be labeled positive or negative or universal but other than a possibly shortened life, as long as the car is charging then it is working. For best spark efficiency the coil should match the battery polarity so with a negative ground, the negative terminal on the coil should be connected to the distributor.

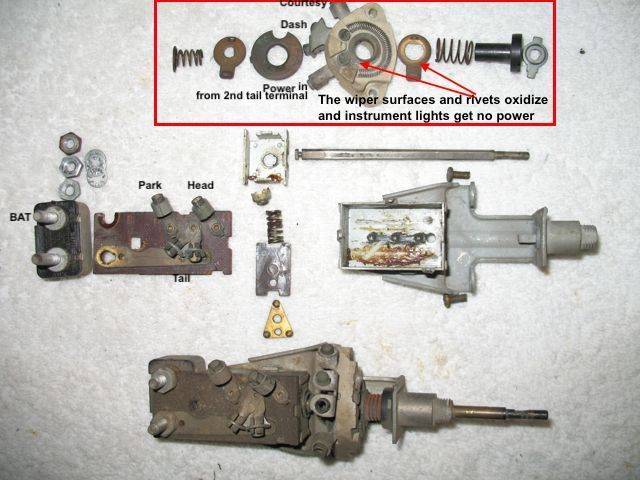

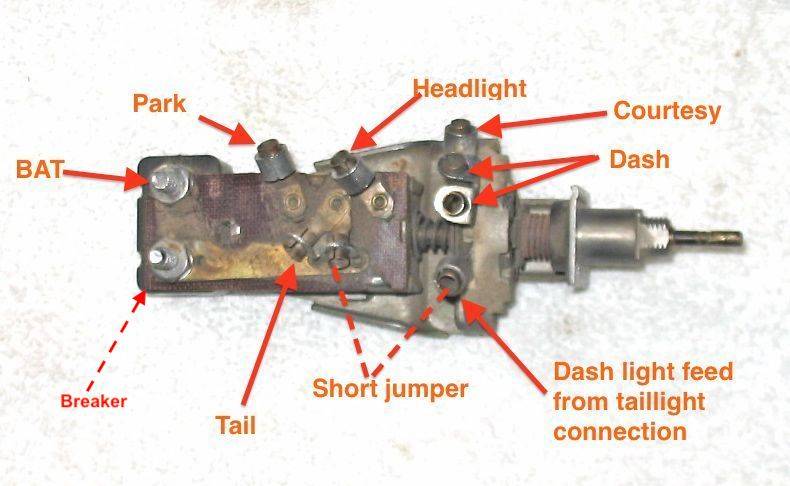

The gas gauge reading backwards has nothing to do with polarity. All the gauge has inside is a heating coil to warm or cool a bimetal strip. To read backwards, I suspect there is an issue with the sender. Possibly the original sender failed and an aftermarket universal sender was installed incorrectly or a GM sender with reversed resistance was tried. What you need has a resistance of approximately 73 ohms at empty and 10 ohms at full. Repro senders are available from our vendors or some Ford senders of the mid to late 50s are also compatible. With the Ford items you need to get one with the correct arm length. To test the sender, if you disconnect the sender wire at the tank end going to the gauge, the gauge should read empty. Touch the wire to ground and gauge immediately starts going to full. Do not leave the wire connected to ground longer than it takes to verify the gauge will go to full. To test the sender itself will require an ohmmeter set to the 100 ohm scale. One lead on ground, the other to the disconnected wire from the sender and you should get a reading. With the sender still in the tank there will be only one value depending on fuel level so sender needs to be removed and arm moved thru its range for a complete test. The cluster lights not working are a well known issue and generally caused by an oxidized or dirty wiper or terminal contact in the headlight switch rheostat section. Sometimes cleaning with contact cleaner or a tiny dab of valve grinding compound on the wiper surface followed by a rapid back and forth movement and then a thorough rinse will restore contact but often the cleaning fix is short lived and other options need to be explored. The switch rheostat section is riveted together and does not come apart easily so any cleaning needs to be done with the switch intact. Attach file:  51-6 Headlight switch Exploded view.jpg (55.02 KB) 51-6 Headlight switch Exploded view.jpg (55.02 KB)  Headlight switch terminals.jpg (50.41 KB) Headlight switch terminals.jpg (50.41 KB)

Posted on: 2023/7/13 13:06

|

|||

|

Howard

|

||||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

What else can I use for a bezel tool? Has anyone tried drilling through an allen wrench?

Posted on: 2023/7/21 11:30

|

|||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

Allens are typically hardened (or at lease case hardened) but you can easily do it with a length of hex stock.

Posted on: 2023/7/21 11:57

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Webmaster

|

Brass stand-offs they use on computer motherboards are nearly the perfect size and already have a hole in them.

Also, at one time, I know David Moe (Seatle Packards) bought boxes of the tool made by Dan Yocum from his estate many years ago. Also, a piece of brass or aluminum pencil rod could be ground to shape pretty easily.

Posted on: 2023/7/21 13:05

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Home away from home

|

You don't want to grind aluminum as doing so could cause the wheel to explode. If you do grind aluminum, use lots of cutting oil! As a journeyman prototype machinist, that is one of the first things learned in the trade. Brass and other non-ferrous metals are similar but not so bad as aluminum as it gums up the pores in the wheel.

Posted on: 2023/7/21 13:20

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Webmaster

|

I use rolock sanding disks. Not grinding wheels.

Posted on: 2023/7/21 13:50

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

I like the idea of stand-offs. I'm not a machinist by any means nor do I have the equipment to try.

Posted on: 2023/7/21 19:17

|

|||

|

||||

|

Re: MikeSC's 1955 Panama

|

||||

|---|---|---|---|---|

|

Not too shy to talk

|

Quote:

Also, did I mention I'm completely new to Packards? I knew of the cars but, was never knowledgeable about them. I got lucky with how I got the car. I've also found myself in the middle of a rather steep learning curve. So thank y'all for the help.

Posted on: 2023/7/21 19:22

|

|||

|

||||