|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

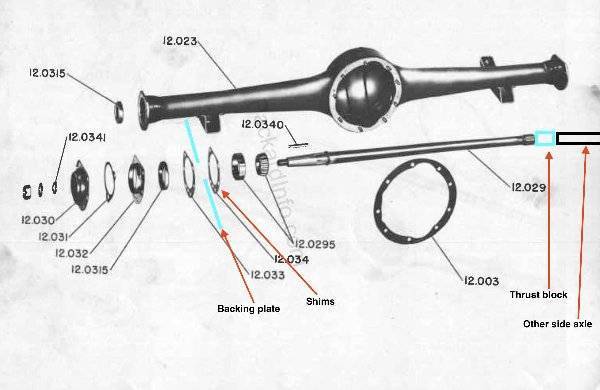

Believe the backing plate is actually what holds the axle in. I've drawn it in below for reference. Can't remember without looking which side the gasket goes on but think I show it correctly with the shim(s) being only thing between plate and axle housing.

The taper roller bearing is against the lip on axle on one side and contained by the bearing cup on the other side. The bearing cup should be a larger diameter than the hole in the backing plate. Shims are placed between the backing plate and axle housing to adjust the end play but once the backing plates are tight there should be no way for the axle to move outward more than the thickness of the shims before the cup presses against the backing plate. Both axles work in tandem with a thrust block inside the differential between the ends of the axles. Axles press against the thrust block but not attached. End play is adjusted so there is the specified clearance and any expansion won't be enough to lengthen axles and cause the bearings to tighten or bind. It is possible to break the thrust block but don't believe it can fall out of position and become ineffective.. If it were not in position the axles would want to move inward. The taper bearings can let the axle move inward until they hit something in the housing but not outward. If the axle was was moving in slightly the drum could be scraping against the backing plate but I would think you would be having other larger issues too.

Posted on: 2016/6/7 15:36

|

|||

|

Howard

|

||||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I have seen a car where the tapered bearings were installed backwards on the axle shafts. The axles were only sort of loosely trapped in place behind the backing plates and of course there was a ton of endplay and clearance problems.

Posted on: 2016/6/7 20:19

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I don't understand. How can the axle scrape against the brake drum when the two of them are solidly fastened together? And how can the axle migrate outwards more than what you've allowed for with the end-play adjustment - the bearing cup which contains the bearing backs against the backing plate. And you mentioned "adjustment" of the key and keyway - no adjustment, you just put the key in the slot.

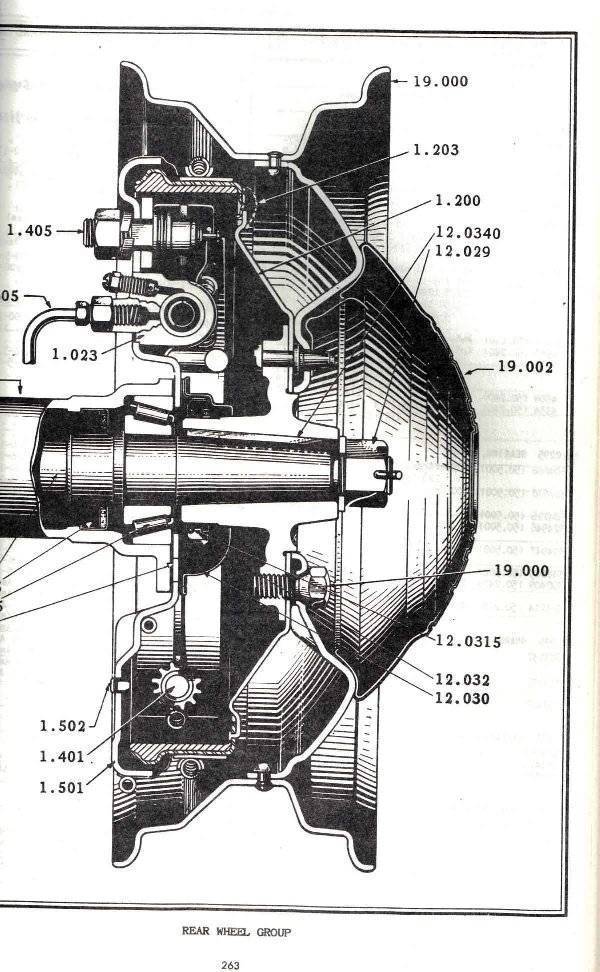

Something should be very apparent - it's a very simple assembly. And please, axle, not axel. Maybe the attached will help you visualize how it goes together, it's from an earlier year but essentially the same. What's the chance that when you ground the end of the drum hub that you removed so much that the axle retaining nut and washer no longer can pull the drum tight on the taper - see the slight clearance in the illustration between the step at the outer end of the taper and the hub? If you ground off enough to eliminate that clearance the drum and axle shaft can no longer be properly fitted - grinding the end of the drum hub was just a very bad idea.

Posted on: 2016/6/8 8:54

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Steve-52/200

Check the topic "Rear Wheel Bearing Replacement' posted by Packard 1948 . . . lots of shimming information. Below I present an alternate explanation on what the service technician is striving to accomplish while following the service manual bearing shimming procedure. Consider the thrust block and both axles, complete with bearings, sitting on your workbench on "V' blocks. Your mental picture should have the splined ends of the axles facing each other with the thrust block between just as they are assembled in the car. Consider the distance between the out-board faces of the bearing cups with zero internal bearing clearance. To that number add the Packard recommended bearing clearance of 0.004 - 0.007 inch. This dimension represents the distance that must be achieved between the inner surfaces of the backing plates of the rear brakes. Here I'm talking about the area where the bearing race touches the backing plate. Shim stock is used to accurately adjust the position of the backing plates. That's the high level view, and mental exercise of what is trying to be achieved. Now let's consider the bearing cups. The outer diameter of the bearing fits into the 'rear-end' housing bore with a minimum radial clearance, but after sixty to seventy years the fit could have lost a bit of its precision. Since forces can only be transmitted across a bearing at right angles to the roller track, the forces ( that would be the vehicle weight and cornering loads) would tend to push the bearing cup 'hard' onto the backing plate. I doubt whether the cup ever leaves contact with the backing plate during the life of the car, but if it does it's not for long. About the shims; they are stamped from steel shim stock in 3 different thicknesses, namely 0.005, 0.007, and 0.020 inches. They have 6 total pierced holes, 4 for the bolts that hold the backing plate to the axle housing, 1 for a grease/oil relief passage (so the grease or oil from a leaking seal does not contaminate the friction surfaces of the brake shoes), and finally the large hole in the middle. This center hole is large enough for the bearing race to pass through. The fit of the center hole to the outer diameter of the bearing cup is quite precise on the OEM shims I've encountered. I believe the design intent is for the bearing to touch the face of the backing plate, and the shim will never be contacted by the face of the bearing cup. I equally believe the Packard design engineers expected each rear axle assembly would be selectively shimmed and designed (and exploited) a minimum and maximum expected amount of shims in each unit by controlling manufacturing tolerances of the component parts. By accepting a shimming process during assembly, the tolerances of the individual piece stack-up does not need to be controlled to the 0.003 suggested by the bearing clearance tolerance (wider acceptable tolerances at the piece part level should be easier/lower cost). I do not believe the procedure presented in the service manual was followed production floor during assembly of the 'rear-end' assembly. One alternate method would be to directly measure the axle detail, and then measure the housing and scribble some arithmetic for the necessary shim stack. However, the most probable alternate method would be to push one bearing cup to a known shim position, which easily could be zero ( no shims using fixtures not backing plates), and then measure how much the other bearing cup is sticking out of the housing. All of the values, including the desired clearance would be combined and the specific shim stack selected, and then divided in two for installation. Once the vehicle has left the production assembly line the service manual procedure is quite adequate, but a bit cumbersome for production. If you have both sides disassembled you could easily get into the right ballpark by using the second suggested alternate procedure. Initially I was taken by the fact that there are only 3 different shim thicknesses. However by selecting various shims you can find a solution (lots of solutions beyond 0.014) that lies within the tolerance of the 'target' bearing clearance. Try it, quite clever those 'old-timers', and an affordable computer was decades away! Now on to the 'funny' noises: When the bearing is rolling on the outer race no matter how the backing plate was shimmed the relative position of the backing plate and rotating drum are just as the design engineers expected (assumes nothing is worn-out). Now let's go into a turn and push hard until a bearing reacts out the cornering forces. One bearing is 'taking the load' and all of the brake drum to brake shoe dimensions are OK on that side. On the other side however the tire/wheel/hub/brake drum keeps moving inboard until the axle touches the thrust block and stops only when the thrust block encounters the other axle (which is hard on the bearing). Too much motion of that axle looking for the thrust block can result in the brake drum operating closer to the backing plate (shoes, cylinder, adjuster, etc.) than expected. Extra shims would make the condition worse. With both rear wheels off the floor, and the brake drag adjusted out, have a 'helper' pull 'their' wheel trying to pull the tire off the car. All the while you're on the other side trying to push your wheel toward the center of the car. While you're pushing and they're pulling try to rotate your side. If the noise is a result of not shimming the bearings correctly you should be able to tell by using this procedure. Reverse your roles (you pull, they push and rotate) . . . the other side is also likely to make noise because the 'shimming' clearance is the same on both sides. With both wheels off the floor and your helper pulling on their tire you should not be able to feel a lot of bearing clearance when you push and pull on your tire, 0.004-0.007 inch is pretty hard to feel. If you're really off on the high side with the amount of shims you'll feel the 'slop'. Reference the diagram Owen included in his reply. If the noise is a result of excessive 'shimming' I don't know which part might be contacted first but you might see witness marks on the drum's 'diaphragm between the intended friction surface and the hub, (rubbing the metal edge of the shoe, or the side of the friction material into a wear lip in the drum ). I have no idea what the design clearance would be between the stationary parts and the spinning ones inside a drum brake, but we do know the full bearing clearance would need to be accommodated. I sympathize that modern mechanics don't not study or have experience with historic designs. It would take them some amount of time 'studying' the photos and 'cut-away' drawings to understand the intent. Hope that helps. dp

Posted on: 2016/6/8 19:17

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Are you saying that the two bearing cups, axles (with fixed thrust bearings) and the thrust block are in direct contact end-to-end and that they float between the backing plates. The diameter of the center holes in the shims is larger than the bearing cup diameter, allowing both cups to move.

I guess this means that if you attach one backing plate without any shims against the housing then attach the other backing without any shims against the protruding cup, then the distance between the backing plate and the housing is the starting point to which the end play is added. How much is this end play? The measured value and the end play should be added and the sum divided by 2. This amount should be shimmed on both sides, centering the thrust block. Does that sound right?

Posted on: 2019/4/17 16:15

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It is not necessary to equalize the shims side to side, you can shim entirely from one side as long as the amount is less than some stated maximun value (maybe 0.060"?) So check the manual for specifics.

DP, what a absolutely splendid explanation of axle shaft end play,my congratulations!! IMO that should be saved somewhere where it can be easily found. Just a note that it does not apply to all Packard rear axles.

Posted on: 2019/4/17 17:02

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Home away from home

|

If anything take the other side apart and compare it since it appears to be correct and working without any problems. Also take lots of pictures and study how it all comes apart. Also post some pictures maybe we can see something your missing.

Wes

Posted on: 2019/4/17 18:03

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Home away from home

|

To answer 'kunzea';

Yes that's what I'm saying, but let's not forget the operating clearance. Measure how much the bearing cup is sticking out of the housing, add the clearance, and that's the total amount of shims needed. Remember in this procedure one side of the car has zero shims and there is a force applied to push everything to that side. Once the weight of the car is applied to the tapered bearings the outer races should be pushed to the backing plate, and I don't see any force that would push it back away from the backing plate, so I believe for the rest of the car's life the outer cups will be essentially in contact with the backing plate, and the clearance is apportioned between the bearing rollers on each side of the car. The weight of the car also pushes both axles inboard, such that the thrust block is 'pinched' between the two. I think the factory may have used the method you suggest, that is one side at zero, that is the bearing outer race cup neither proud or shy of the housing (this could be done with a fixture not a backing plate), and make a direct measurement of how much the other side's outer race is sticking out of the housing That's with some amount of force pushing all of the parts together, which could be a weight if the housing is vertical. Once you have that value the desired clearance would be added to compute the total amount of shims desired. That value is split 50/50, or as close as equal as possible, and shims and backing plates installed. Now all of that assumes that the thrust block can slide to the extent required by that simple procedure, but that could be checked before the process starts. I agree that is business of a 50/50 split of the shims is not totally required if you understand the thrust block can accommodate whatever the actual shim split will be. OD, thank you for the kind comment. I understand the V-12 design that uses 4 total bearings. I think the applicability is for Packard rear ends that have a single tapered bearing on each side of the car. When I started working on cars the single bearing design had moved-on to a ball bearing design that didn't need shimming, and I think Rambler was the last holdout with the tapered hub design . . . another design industry set aside. dp

Posted on: 2019/4/17 18:33

|

|||

|

||||

|

Re: The rear axel blues!

|

||||

|---|---|---|---|---|

|

Home away from home

|

DavidPackard,

Thank you for your confirmation and elaboration. Other than possibly having to make shims from shim stock, I believe I'm in good shape regarding replacing the bearings, cups, seals, shims (re-use some) and gaskets. I have the bearings/cups in-hand. I ordered on-line a seal/gasket kit. I also polished the axles' machined surfaces with folded-over strips of 220 sandpaper and Brasso. They are not perfect but are close. No thumb nail drag. This was precipitated by the left drum being locked-up. The wheel cylinder wouldn't retract. The right-rear had serious oily grime built up on the back face of the blocking plate. I also am replacing the master and wheel cylinders and the hardware. I freed-up the upper brake shoe adjustment cams, wire brushed everything (radial wire wheel in drill) and reassembled. The shoes and star adjusters were re-used. I do have an issue with leakage from the pinion shaft seal. Can this be replaced without removing the carriage?

Posted on: 2019/4/18 8:22

|

|||

|

||||

(119.28 KB)

(119.28 KB)