|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

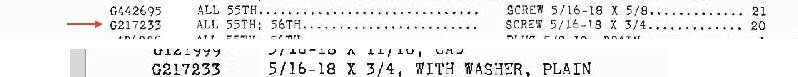

Here is the original spec on pan bolts. 5/16-18 and 3/4 long is used with the 56 aluminum trans cases. Most of the threaded holes in the aluminum cases are thru holes and could possibly be drilled and retapped larger with a corresponding enlargement of pan holes if there is enough excess metal surrounding the hole. Others are closed end and would need a bottoming tap. Some at the front could also be very close to fluid passages inside the case.

Has your mechanic checked the straightness of the pan mating surface itself? That is a frequent cause of leaks because the pan is stamped from fairly thin sheetmetal. When the bolts are overtightened the metal around the holes is distorted and pushed upward as the relatively thick cork gasket compresses directly above the bolts. Even with a new gasket if the metal is distorted the bolts stop applying much pressure when they reach the gasket. When that happens there is not enough compression on the gasket in the relatively long spaces between holes so a leak is the usual result. Check with a good straightedge laying across the lengths of the pan bolt hole mating surfaces. Use a small rounded end hammer and GENTLY tap down and flatten or even slightly depress any metal around the holes that is above the surface as shown by the straightedge. The same issue and check applies to the engine oil pan.

Posted on: 2023/4/11 8:53

|

|||

|

Howard

|

||||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

As always Howard offers comprehensive replies and good suggestions. You may also want to consider repairing the damaged threaded holes with a thread repair kit like Heli Coil.

Posted on: 2023/4/11 10:52

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Over the many years I have owned and worked on my V-8 Packards, I have encountered many similar instances. Most of the time people treat the 1956 aluminum transmission as if it is a 1955 transmission case. Result is sometimes the aluminum threads strip out. I had a friend who once did this swearing he used torque specs right out of the "Packard Shop Manual." But that manual turned out to be 1955 with no 1956 info included. In the end, every joining bolt around the bell housing going into the main body was stripped to the point of useless. Get yourself some Heli-coil repair kits, use 1956 torque specs and you should be back on the road.

Posted on: 2023/4/11 11:16

|

|||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

I agree with Leeedy and others that Heli-coils or an equivalent thread repair are the way to go and use stainless..

Posted on: 2023/4/11 11:48

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Quite a regular

|

Thank you Howard and Leeedy for the excellent information and advice. This is such an amazing forum and a great group of people. I really appreciate it.

Posted on: 2023/4/11 18:59

|

|||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Quite a regular

|

I just wanted to send a thank you and follow up message. My problem turned out to be the oil pan being overtightened and warped. To give you a little bit of a back story. I bought the car January 2022. I took it to an "old car mechanic" in upstate New York. Someone recommended him, and he had a DeSoto sitting out side, so I figured how bad could he be... He replaced the oil pan gasket, and complained that transmission fluid was coming out of the screw holes. He said that he fixed with RTV.

Last year I moved to Finland, and this time I decided to give it a shot myself. I removed the transmission oil pan. While cleaning the pan, I found multiple colors of sealers and gaskets. All the bolts and bolt holes were also covered in RTV. With a straight edge, I could see that the first edge of the pan was relatively straight, however the metal around the bolt holes were all warped. I ended up putting a few blocks of wood for support, and using a hammer and a large round bolt to tap all the bolt holes back down. After cleaning all the bolts and bolt holes, I put in a new cork gasket. I didn't use any RTV, just a bit of vaseline on the gasket, and hand tightened the pan. After a few weeks of driving, the transmission pan has held well. I still have a ton of leaks to fix, but at least the big one is now done. Oh, and for the loose bolt. Someone had drilled out one of the bolts through the transmission, and replaced it with a longer bolt and nut on the other end. For now I just put it back in since the gasket works.

Posted on: 2023/5/15 5:28

|

|||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just where are the specs for the 56?.

I have yet. To find them.

Posted on: 2023/5/15 9:33

|

|||

|

Riki

|

||||

|

||||

|

Re: Twin Ultramatic Transmission oil pan bolts

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

A lifetime transmission rebuilder friend of mine runs transmission pan bolts down until they are just barely snug then turns them all 1/4 turn more regardless of the torque.

I thought it was nonsense until I thought about it this way: The goal is to produce the correct amount of "squish" on the gasket. What if the gasket is wider in some areas that others? Those wider areas would squish less than the narrower areas if the bolts were all torqued the same. It's all related to surface area and pressure per square inch. It would take more turns of the bolts in the narrower areas to reach the same torque. By running all the bolts down snug, then turning them all the same amount, you produce the same amount of squish across the entire gasket. Then it made sense to me.

Posted on: 2023/5/23 5:49

|

|||

|

1955 Patrician.

|

||||

|

||||

pan bolt.jpg (38.48 KB)

pan bolt.jpg (38.48 KB)