|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

Didn't Continental supply Hudson with their engines?

A Continental engine plant (still standing, barely) backed up to the main Hudson plant at Jefferson just north of Conner. I have read that this was done so the engines could be easily transported to Hudson's production line.

Posted on: 2013/4/14 19:21

|

|||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

I wouldn't drive a Chrysler if the only alternative was a unicycle. The Chrysler attitude towards skilled and educated people is the worst since Nazi Germany

Posted on: 2013/4/14 19:27

|

|||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Didn't Continental supply Hudson with their engines?

Continental supplied Kaiser-Frazer and Checker postwar, DuPont, REO, some Peerlesses and others in the 30s, but Hudson made their own engines. Hudson's engine blocks were unique to Hudson and quite different than the Continental flathead 6s. The only connection I'm aware of is that Hudson blocks, heads, etc. were cast by Campbell, Wyant & Cannon (that's the CWC foundry mark on their blocks and other castings.) who also did casting work for Continental.

Posted on: 2013/4/14 22:51

|

|||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Didn't Continental supply Hudson with their engines?... Dezi (Pack120c), according to the Times Colonist, there was a strong connection between Continental and Hudson in the first years of the 20th century. Quotation from the article: "Continental: Engine-maker to the industry": "...Then in about 1910, the recently formed Detroit-based Hudson Motor Co. ordered 10,000 engines, and the young Continental company was on its way..." Dave (Owen_Dyneto) is right in saying that Hudson made its own engines when it comes to later years, says Charles K. Hyde in "Storied Independent Automakers" (see below). Attach file:  (34.09 KB) (34.09 KB)

Posted on: 2013/4/14 23:41

|

|||

|

The story of ZIS-110, ZIS-115, ZIL-111 & Chaika GAZ-13 on www.guscha.de

|

||||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hard vs. soft = 100K mile engine vs a 40K mile engine. HUdson also used an additional oil ring below the pin. So maybe Hudson was trying to beat the competition. Hudsons problem was a lousy dealer network = UNcompetitive.

Posted on: 2013/4/15 7:06

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

As for Continental, idk about the very early years prior to the late 30's. The 40's and 50's engines were not anything near excellence at all. However one mite argue that Cont made engines to corporate customer specs. I remeber several oldtimers (seasoned mechanics and eng'eers) often commenting that the Cont's were not desireable engines.

I currently run late 40's early 50's Z120's and repairing another. NOTORIOUS for INTERNAL block cracking even if just slightly overheated. No cam bearings inserts. Very reliable for starting and power under very adverse conditions yes, but it has some very undesireable design features.

Posted on: 2013/4/15 7:28

|

|||

|

VAPOR LOCK demystified: See paragraph SEVEN of PMCC documentaion as listed in post #11 of the following thread:f

packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=7245 |

||||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

As for Continental, idk about the very early years prior to the late 30's. The 40's and 50's engines were not anything near excellence at all. However one mite argue that Cont made engines to corporate customer specs. I remeber several oldtimers (seasoned mechanics and eng'eers) often commenting that the Cont's were not desireable engines.

PackardV8, I'm afraid we've deviated from the original poster's request of no conjecture - just facts, so I'm a bit reluctant to add this, but I've never heard anything but high praise for the postwar Continental 226 ci engines. Certainly their use in Checker cabs would have been a pretty severe test. It could be otherwise, but that's what I've heard. OK, for me back to the original question and facts only.

Posted on: 2013/4/15 11:20

|

|||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dr. O'Dyneto -- Thank you, sir. This has devolved to some sort of parallel universe show and tell. Meanwhile, sportsfans, it's okay if you don't have the answer.

Please, don't feel compelled to post just to show us your collection of "ESSO terica." I certainly don't have the answer, and haven't been able to unearth it, hence my quest here.

Posted on: 2013/4/15 14:57

|

|||

|

||||

|

Re: Hard vs. soft engine blocks

|

||||

|---|---|---|---|---|

|

Home away from home

|

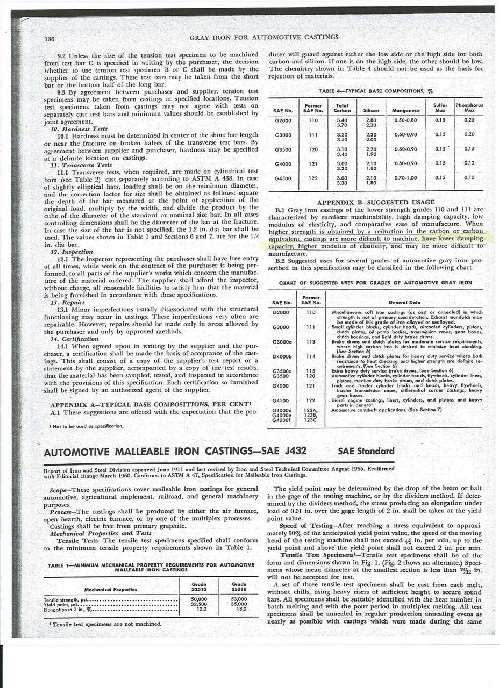

This may explain the use of soft rather than hard cast iron in Packard blocks. All Companies make parts to drawing which include a bill of material which may include sizes material to be made from sometimes referred to as material spec a normal standard for material SAE. The page I have included is from a SAE handbook. SAE has been around since the early 1900 started by automotive engineers for standards and to share information. States higher strength is gained by reducing carbon at the loss of some damping capacity. Could be Packard wanted the damping effect to add to silence of running engine.

Not knowing what the engineers specified but sure they knew why and what they were using and Quality Control made sure they got what they specified

Posted on: 2013/4/15 22:17

|

|||

|

||||