|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Home away from home

|

Dear Tommycourt:

Both cylinders likely have valve seating problems. You can confirm by doing a wet test. If the readings don't change much then you have valve problems. (Excluding holes in the pistons.) The readings you are getting are on the high side and indicative of significant carbon and cylinder head planing. So don't plane the head. I assume you haven't had the motor running. Usually if the oil pressure is good and there are no knocking sounds then you can go ahead and do a valve job in your driveway. Have the valves ground at a machine shop and lap them in. If they all seat then put it back together, but make sure you polish the stems if they are pitted. This will provide a limited use vehicle for short haul moderate use assuming the timing chain is good. Packard actually authorized reusing head gaskets that were in good condition. So be extra careful and store the cylinder head on its side to prevent distortion. Be careful about dirt and use cheap oil for start up and change it after 30 minutes around the block to flush the motor of dirt from the service. Good luck.

Posted on: 2011/3/31 17:14

|

|||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Tim gives good advice, as always. I can only add that you may want to drop the pan, pull a couple of main and rod caps, check the crank journals visually, and check the bearing clearances with PlastiGage. Not a lot of labor to expend for what you can learn about the engine's condition. Easy then to give a poke at the timing chain for slack.

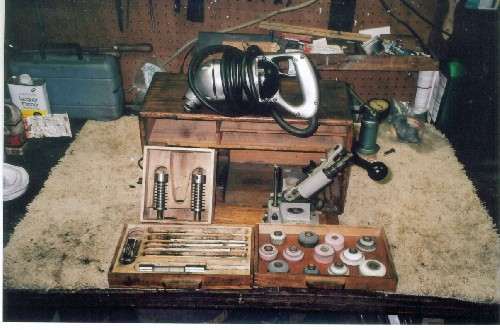

If you do a valve job, there's a reasonable chance that the exhaust valve seats may be too beat to expect good, long-lasting results by just hand-lapping with new or refaced valves. Portable equipment for refacing the seats might be found at an old-time auto shop, hopefully with the guy who knows how to use it. Picture of my equipment below so you know what you'd be looking for. To answer another of your questions, the 288 is a very sturdy engine, but like any other, time, mileage & neglect can take their toll. Best to take the time to find out what overall condition it's in before any serious driving, and certainly before considering a "rebuild". I would not assume that failure to go into reverse is a clutch issue without other indications. Yeah, your other compression reading are REALLY high.

Posted on: 2011/3/31 17:44

|

|||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

It's possible the shift linkage is out of adjustment on the car. If the 2-3 fork is not at the neutral position, the interlock may not allow the 1-R to shift properly. The problem could also be worn or damaged parts. Here is a link to a 1946 service counselor with a quick adjustment check procedure. Use the one for Clipper as it is very similar to your car.

packardinfo.com/xoops/html/downloads/SC/SC-VOL20NO5.pdf If adjustment does not do it, then there is a transmission and overdrive training manual or the section on trans and overdrive in the service manual (both available in the service, shop and training manuals section of literature) which will give much information on service and operation of the trans and some various symptoms and things to look at to correct a problem. As you have overdrive, some problems there could also prevent reverse. Does the shift lever move an amount about equal to second where it should go into reverse but nothing happens or does it seem to jam or stick in it's travel to the reverse position. Many have experienced problems with the sticking and have found a lack of lubrication. There is a small hole in the gear shift tube in the area just above the shift levers exiting the tube near steering box. A few drops of oil in that hole has helped.

Posted on: 2011/3/31 17:47

|

|||

|

Howard

|

||||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Tommycourt, I don't know how mechanically adept you are, but even if you're not going to do a valve job yourself, you might want to browse the following just so you can have informed discussions with your mechanic. I don't know how many valve jobs I've done on Packards, but it's MANY. So don't be shy in asking questions. Lots of other on here with equal experience.

packardclub.org/forum/viewtopic.php?f=14&t=862

Posted on: 2011/3/31 17:54

|

|||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Home away from home

|

I've been driving Packards since the 60's, when they were just used cars. I had one in the 70's that I decided to pull the head, and managed to mess it up pretty badly by using brute force rather than smarts. When I rebuilt a 51 288 last winter, I bought four Purdy putty knives, about 1" wide, and sharpened them on the grinder to a very long taper. (Purdy knives have the metal going all the way to the end of the handle - a good thing to have) I pulled all of the head bolts, and very carefully went around the head, tapping in the putty knives between the bolts, using a dead blow mallet. I had the head attached to the engine hoist and put just a little pressure on it. After two times around, the head popped right off. It also helps to put PB Blaster around each headbolt, as it the corrosion around the bolts that makes it difficult to pull the head. Please note this is a sure fire way to mess up your head gasket. Don't get crazy on the hammering and you shouldn't scratch the head. Course you might get lucky and not need this technique. But it worked for me on two engines.

Posted on: 2011/3/31 19:21

|

|||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Just cranking the engine over with the starter motor with the spark plugs in place, the headbolts and other hardware removed, and the ignition disabled is another commonly used method.

Posted on: 2011/3/31 20:01

|

|||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

HH56 wrote:.....As you have overdrive, some problems there could also prevent reverse...... Regarding O/D and reverse, you need to be locked out of O/D to be able to engage reverse. May be as simple as that. If not, its also been known for the reverse lockout between the Trans and O/D not to function properly. If that's the case O/D should be removed from rear of Trans and things properly aligned and put back together again.

Posted on: 2011/3/31 21:31

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Oz said.....If not, its also been known for the reverse lockout between the Trans and O/D not to function properly.

That is sort of what I suspect but need to know if the shift mechanism is going full travel.. As the trans is placed in reverse and shift fork starts moving, unless something is broken, binding or otherwise preventing movement, a rod should slide back and automatically lock out the OD. If it doesn't lock out in reverse, the over running clutch will be rotating but going backward. It will be unable to wedge or mesh against the other part so no power will be transmitted to wheels.

Posted on: 2011/3/31 21:54

|

|||

|

Howard

|

||||

|

||||

|

Re: Advise on a 288 cu inch

|

||||

|---|---|---|---|---|

|

Home away from home

|

In the old days a ring and valve job or top end overhaul was a common way to freshen up an old engine.

How is your oil pressure? How many miles on the engine? If oil pressure is 40 PSI @ 45 MPH it is within factory specs. If it is also 20 PSI hot idling your bottom end is probably in good shape. Especially if the engine has less than 50000 miles on it. You may be OK to grind the valves and put in new rings and go for another 30000 miles. Take off the head and measure the cylinder wear. If the cylinders have less than .007 taper they do not need truing. You can hone them and put new rings on the old pistons. How does the engine run in general? If there are no raps or knocks and the oil pressure is good it shouldn't be hard to put back in commission. By the way flathead engines are not hard to work on. If you decide to do the job yourself it should be possible to rebuild it for around $1000 in parts, just a ring and valve job of course, much cheaper.

Posted on: 2011/4/1 11:45

|

|||

|

||||

(110.69 KB)

(110.69 KB)