|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

that would be amazing for some of the stuff we need.

Can you describe what can/cannot be reproduced on a reasonable basis? Most of us cannot afford to hire an aerospace company.. Materials, machining capability, etc? Thank you. DAF

Posted on: 2022/8/21 20:55

|

|||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Can they do aluminum or potmetal?

Posted on: 2022/8/22 1:44

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Just a note; when you install that thing it should slide into the splines and seat against the crankcase completely with virtually no resistance. The fasteners only serve to hold the unit in place. If it does not slide against the crankcase then something is not lining up.

There is a spring load button in the timing cover but that serves only to control the timing gear. The generator shaft is a full floating affair.

Posted on: 2022/8/22 7:07

|

|||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hi,

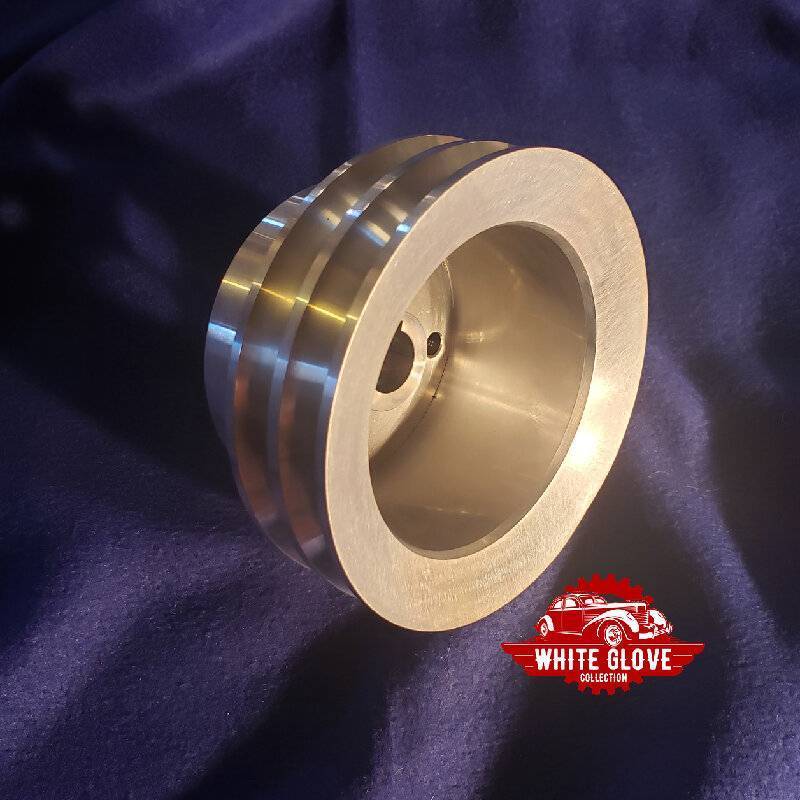

I can reproduce most anything. Nothing too heavy meaning no engine blocks but I have access to a full CNC machine shop, a casting service and 3D printing as well. Between the three I can reproduce just about anything. To answer the question by PackardDon, the machined parts are usually aluminum unless they require more strength. I have reproduced the shackle bolt for my '36 (picture attached) which was made of stainless steel for the required strength. If they are 3D printed or cast we usually use a zinc alloy which replaces original pot metal parts nicely and can be chrome plated with no issues (and they are stronger). Regarding your comment about 'hiring an aerospace company', you don't have to worry about that. I am an aerospace engineer by trade and have spent the bulk of my career, (27+ years), designing parts on CAD so I'm very proficient with 3D CAD design. I have several pieces of software on my home computer. I will gladly design anything at no cost to anyone. I love doing it (plus I get really bored if I'm not working on something). So to sum it all up: - Free 3D CAD design services - Free estimates on what the part will cost to reproduce - Parts can be machined (CNC), 3D printed (with an accuracy of +/-0.001") or cast (casting will reproduce the smallest of details) - No harm will come to the original parts during the casting process - Reproduced parts can be easily chrome plated I added some pictures of various items I've manufactured which are based on original parts that were on my car. One is a water pump pulley, (mine cracked and I could not find a replacement), one is the front leaf spring shackle bolt, the bracket with the hole in it is 3D printed and the others are cast pieces before chrome plating. If I can help, please let me know. That's what we're all here for. Thanks, Crin Attach file:  20201104_145917.jpg (132.29 KB) 20201104_145917.jpg (132.29 KB)  20210910_163336.jpg (156.66 KB) 20210910_163336.jpg (156.66 KB)  bracket.jpeg (106.06 KB) bracket.jpeg (106.06 KB)  casting1.jpeg (30.72 KB) casting1.jpeg (30.72 KB)  casting2.jpeg (50.81 KB) casting2.jpeg (50.81 KB)

Posted on: 2022/8/22 20:21

|

|||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Hello Crin,

Wow! That's a very generous offer. I'm sure there are many desired builds of hard-to-get and nonexistent parts and assemblies being gathered up as I write this note. Thank you. Steve F.

Posted on: 2022/8/23 10:26

|

|||

|

Steve

Old cars are my passion  1951 Packard 200 1953 Packard Clipper Custom Touring Sedan 1955 Dodge Custom Royal Lancer Tri-tone 1966 Rambler Classic 770 Convertible |

||||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

Crin.

What about these.

Posted on: 2022/8/23 15:53

|

|||

|

Riki

|

||||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

That looks like a great candidate for casting. Easy to do.

One note of caution is that the casting process will reproduce every detail from the original part. I see a bunch of pitting on that one so all those pits will be reproduced as well. I would recommend getting the pits out (sanding perhaps or a really fine media in a sandblaster or a wire wheel - just thinking out loud). If you can give me a rough idea of diameter and height I can get you an estimate. Thanks, Crin

Posted on: 2022/8/23 16:09

|

|||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

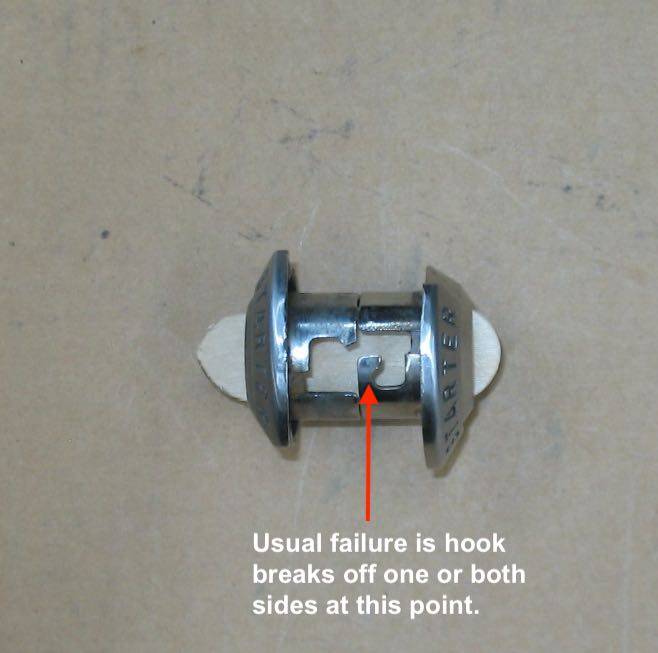

If the 55-6 starter bezels could be repro'd there is certainly a need as I believe it is all but down to finding a good used part now and those are becoming scarce.

The usual failure is the small hooks that hold the ignition switch weaken and distort due to continual pressure from the heavy spring. One or both will be pushed outward and eventually break off at the very narrow point where they join the body. I am wondering how the piece could be cast with conventional sand casting unless there would be a removable or sacrificial core involved. I would imagine when they were diecast there was some kind of multipart mechanical center that expanded and retracted to clear the hooks and allow the release of the part. Attach file:  IMG_2567.jpeg (33.84 KB) IMG_2567.jpeg (33.84 KB)  IMG_2570.jpeg (34.12 KB) IMG_2570.jpeg (34.12 KB)

Posted on: 2022/8/23 16:43

|

|||

|

Howard

|

||||

|

||||

|

Re: Broken cast iron end of Owen Dyneto generator for 1931 Packard

|

||||

|---|---|---|---|---|

|

Home away from home

|

The process is not sand casting. Sand casting makes really rough castings with very poor detail transfer. It's a different type of casting and the original piece remains unharmed.

I just need some rough idea of size to provide an estimate.

Posted on: 2022/8/23 16:46

|

|||

|

||||