|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks, Howard

I will check all that out with the rebuilder. Also, I am thinking of checking with the rebuilder on my original starter to see if he can machine some new holes for the four-bolt solenoid so that it can be positioned to allow better access to the top bolt fastener of the starter. That would entail moving the base plate of the starter as well, so that the steel bullet that goes into the solenoid will be positioned correctly. I will get back to the forum on all this stuff. A very interesting project indeed. Hey, the car is off the road but it's a great learning experience. Best Regards, Warren

Posted on: 2017/12/28 16:48

|

|||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Home away from home

|

What makes a starter hi torque?

The motor or the ratio of the part that engages the flywheel?

Posted on: 2017/12/28 17:21

|

|||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

The flywheel engagement ratio is fairly well fixed because of the engine design. Due to whatever is bolted to the flywheel and the diameter of the bellhousing and starter pinion location, the flywheel size and pinion size is fairly constant.

The motor itself can have different characteristics. In a permanent magnet motor it could have stronger or more permanent magnets or a differently wound armature so that more coils are energized via the brushes at a time. Anything that increases the magnetic attraction between armature and field will make it stronger. In an old style field coil motor there could be more copper and more coils or larger pole shoes so more magnetism is created. IIRC, one of the old starter catalogs defined their different versions as having two field coils and shoes in the standard starter while a high torque version had four. The armature output could also go thru a gear reduction stage to considerably increase the torque available. A planetary stage is what most of the modern permanent magnet hi torque starters are using. The old gear reduction starters like the 356 engine used have a spur gear setup.

Posted on: 2017/12/28 18:15

|

|||

|

Howard

|

||||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

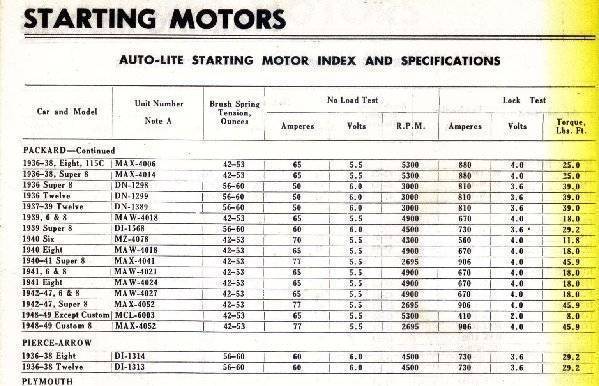

From Motor's. Don't undersize the starter.

Posted on: 2017/12/31 12:30

|

|||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Wonder if that is a misprint for the 48-9 engines and it should be 18 instead. 8 ft/lb seems very low for a long eight cylinder engine -- even lower than the 11 ft/lb used on a six. If it is truly 8 then I would stick with the original starter.

The 45 ft/lb for the 356 engine is quite a jump and I wonder if that engine is so drastically different in friction from the earlier engines or a 327 or 359 nine main to require it. Maybe there is another reason for the gear reduction starter. If specs in service counselors are accurate there doesn't seem to be much rationale to starter choices as far as torque. According to the 53 specs the 288/327 5 main engines used a starter with a stall torque of 16 and the senior 327 with 9 mains had 25. In 54 they backed down to 15.4 across the board including the 359.

Posted on: 2017/12/31 12:47

|

|||

|

Howard

|

||||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

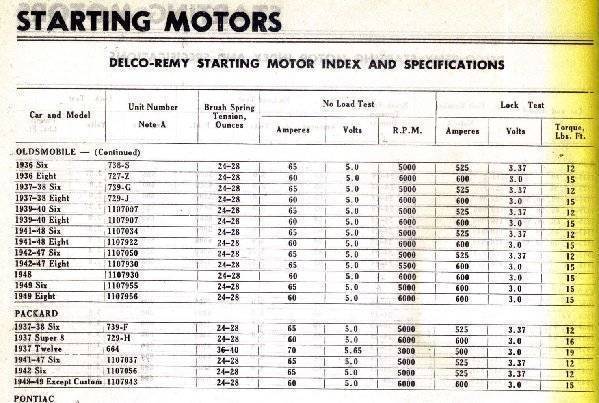

Howard, I don't think a "neat and tidy" correlation between starter torque and the size of the job (engine size, compression ratio, etc.) is to be found. Compare the Pierce Twelve, similar CI and CR but 3 more main bearings, to the Packard Twelve. I'll post the Delco chart shortly, shows more of the same.

Here's the Delco-Remy data. Note the torque on the Delco unit for the Twelve, versus the Dyneto units, the Delco for the Twelve in '37 was a one-year only event, I wonder if it was found wanting?

Posted on: 2017/12/31 13:45

|

|||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

the Delco for the Twelve in '37 was a one-year only event, I wonder if it was found wanting? Could be because it is about half of the rating given for the 36 and 38 units and I would think the twelve would be an engine needing a fair amount of torque. The Delco 48-9 spec at 15 ft/lb would seem to indicate that the Autolite chart is a misprint. Believe Delco was considered the smaller offering in those days so if the Autolite is really 18 that would fall more into line.

Posted on: 2017/12/31 15:15

|

|||

|

Howard

|

||||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Home away from home

|

I want to mention that I took over the restoration of the car from the previous owner who had the engine rebuilt.

When I started the car it did so easily with very little cranking. Almost at once it started idling very rough and with a clunking noise. Every once in a while the noise would go away and the engine idle smoothly. I shut the engine off after about 15 seconds. My first though was a valve that was sticking. I open the hood so I could be on the valve side of the engine. I restarted the engine and had the same results. It seemed that the noise was coming from the rear of the engine around where the tappets and rocker arm levers are. I had the air cleaner off and noticed that the aspiration noise I heard coming from the carburetor would change when the engine ran smoothly versus rough with clunking noise. Not want to cause any further damage to the engine, I did not rev it up nor run it any long than necessary to make a guess as to the cause. I'm guessing that the issue is with a rocker arm or may be a tappet. At this point, I want to examine all of the rocker arms in order to ensure that the cam does not get damaged. My next steps will depending on what I find out. I was wondering where this ended up. It was suppose to be posted on the Pre War Blog I had going on my engine noise. Sorry if I cause any confusion

Posted on: 2017/12/31 20:49

|

|||

|

||||

|

Re: Threaded Post On Delco Starter

|

||||

|---|---|---|---|---|

|

Home away from home

|

Note the voltage and current for the starters that have the 8 ftlbs zero speed torque specification. The listed torque may not be an error.

I have a '54 'Motor's' manual that has a diagram of the test set-up for this test. There is a large capacity variable resistor used to set the tabulated voltage. I suspect the current and torque are the two characteristics that should be compared to the tabulated data. If I was conducting this test I would start-off with the lowest voltage achievable, and then ramp to the tabulated voltage level . . . all the while keeping an eye on the current. Once at the correct voltage the torque would be read and recorded. dp

Posted on: 2017/12/31 21:35

|

|||

|

||||

(197.24 KB)

(197.24 KB)