|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

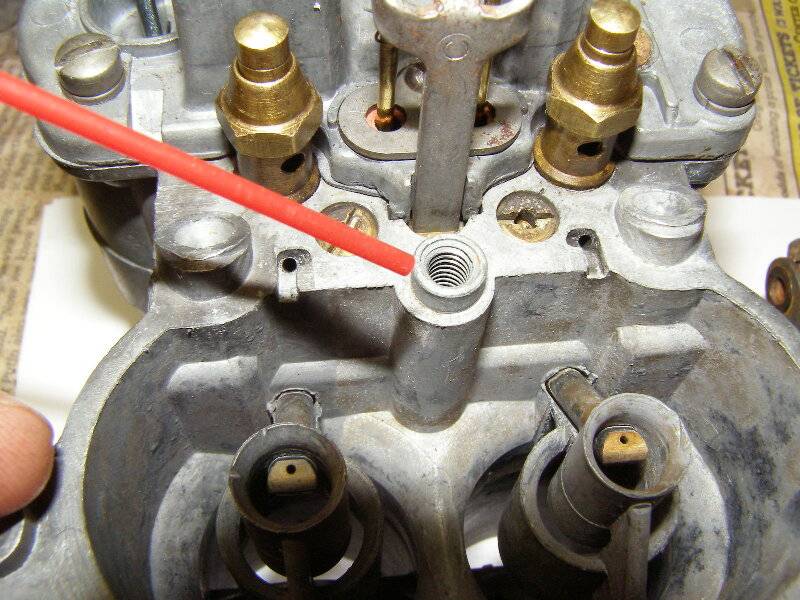

I believe that is the accellerator pump check valve. If the accellerator pump nozzle goes on the threaded hole near the red line, i believe the needle is dropped into the hole, point down, and the ball is dropped on top it, then the pump nozzle is installed using the correct screw. The purpose of the needle and ball is to prevent carburetor vacuum for syphoning gasoline through the accellerator pump nozzle at higher speeds. (That's what I think it is. A good diagram of your carburetor would be helpful, if one can be found.)

Posted on: 2023/4/30 20:23

|

|||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Here is an early WDO sheet that I believe shows that area in photo 8 and the check ball going in the hole. Don't see the other item but maybe it came after this sheet was published.

Posted on: 2023/4/30 20:43

|

|||

|

Howard

|

||||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

The ball does not go on top of the pointed brass valve, it goes under the accelerator plunger and is held in with a spring wire

Posted on: 2023/5/1 1:54

|

|||

|

35-1200 touring sedan 42-110 convertible coupe 48-2293 station sedan |

||||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Good thoughts, guys.

I have the 1939 Carter directions too & even under enlargement, I am not sure. I have the accelerator ball & spring in (no screen was present on my '40) but the kit came with 2 balls. It does seem like the needle goes down the hole in the second photo. Anyone else?

Posted on: 2023/5/1 16:33

|

|||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

See

packardinfo.com/xoops/html/modules/newbb ... c_id=23113&order=ASC&status=&mode=0 While the artwork is from a WCFB the concept is the same. dp ps If the link doesn't work it is posting 451, page 46, of KPack's 1954 Panama project blog.

Posted on: 2023/5/1 17:26

|

|||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

DP, you are the Man!

I can rest easy, Danke.

Posted on: 2023/5/1 19:08

|

|||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I knew the ball went under the accelerator pump but couldn't figure out where the brass piece went. It's as clear as day on the diagram! I'll be working on one of these pretty soon too so good to know.

Posted on: 2023/5/1 20:01

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I am afraid that I lack the metering rod gage and might have difficulty figuring it out anyhow but it will be some time before I get this hell rocket running.

Things should be in the ball park though...

Posted on: 2023/5/1 21:08

|

|||

|

||||

|

Re: Carter WDO help. This thingy!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Other WDO musings:

For the accelerator pump to work well enough neither valve (ball or needle) needs to seal perfectly. As such, I rarely pull the trash screen just to change the ball. I normally have my Carters apart on about a 3-4 year cycle, for nothing more than a refresh of the fuel shut-off valve (needle and seat), and plunger (acceleration pump), so they are not normally gummed-up all that much. In the past I’ve intentionally adjusted the anti-percolation valves to close late just to see what the symptoms would be. The engine would not transition from the low speed circuit to the main circuit with that adjustment out of wack, so the car was limited to about 20-25 mph. I guess if the AP adjustment was close enough to specification the transition would possible, but perhaps rough. Something to think about if there is rough running during the transition speed. I’ve also messed around with the ‘finger’ (set with tool T109-27, 72, 113, or 117S depending on ‘tag number’) that sets the minimum metering rod position as a function of throttle position. The adjustment that I tried would produce a lean condition, which resulted in a ‘flat spot’ during transition, not as bad as the AP adjustment, but a ‘flat-spot’ none the less. Given the alcohol in fuel these days perhaps this adjustment should be biased a tad rich. I could send a drawing on how to make a gauge out of round stock. What you need is the ability to grind/file a point on one end of the tool (angle TBD), and a means to measure the total length of about 2 ¼ inch (varies by tool number). The tool measurement needs to have an accuracy of 0.005 – 0.010 inch. Plus with homebrew gauging if you want the adjustment to be 0.010 inch more than spec just make another gauge, and zero in on the mixture that has the best transition, and has a smooth transition to and from coasting with OD locked-out. Some Carter repair manuals suggest a new vacuum piston spring at every access, but the kits I’ve bought lately didn’t have that spring. I currently have one #4 stainless steel AN washer (0.040 thickness) shimming the spring, which would be in the rich direction. That seemed to help the transition (especially at very low acceleration rates) well enough to justify a future ‘two washer’ test. I don’t know if I’ve enrichened the mixture beyond the original intent, or just corrected the mixture closer to spec. The time in service of the spring I have is unknown, but could be eligible for social security. Back to the AP valves. I have a WDO intended for a Hudson It was in really bad shape, but while the AP valves looked okay, and open/closed okay when I disassembled them (disassembly of the valve is destructive), one of the internal return springs was broken . . . it looked like a corrosion failure. Those Hudson AP valves have a second life as a set of dummy valves that I currently have in my ’48 (remember a WGD doesn’t have AP valves and my modified WDO doesn’t either). I know if both AP valves remain open, or are grossly late closing, the car will be limited to the low speed circuit, but if one valve got ‘hung-up’ we would likely have, because of the dual plane manifold, a 4 cylinder engine running correctly, but the other 4 cylinders running lean, perhaps lean enough that the ignition is suppressed. Just a lot of cylinder washing, but not a lot of power. I’m still chasing what was wrong with my ’48 when it was running really bad for about 20 minutes, and then cured itself. Because of the timeline of what was going on during that outing one AP valve leaking is still on the list of possible failures, but will not likely be proven/disproven because the evidence is long gone. Installing the dummy valves is an attempt to turn off that failure mode. The thread of the AP valve is a common standard, so an Allen set screw could be used as a plug, but if the carburetor police look down the air horn my dummy valves look like the real McCoy. Back to the Hudson carburetor. Carter seems to have an endless number of main jet/metering rod combinations, and for some reason the main jet diameter is not a common twist drill size (not fractional, number, or letter). The Hudson jet/rod sizes are nothing like Packard combinations, but if the Hudson main jet is paired with a Packard metering rod I believe the new combination will richen about one ratio unit, or just about what was lost when alcohol was added to the fuel. That’s something else I would like to test. That two barrel Holly EFI is looking real interesting . . . except I’d like to keep the car electrical system 6+. dp

Posted on: 2023/5/1 23:44

|

|||

|

||||

P1014418.JPG (59.88 KB)

P1014418.JPG (59.88 KB)

carter_wdo_manual_39_later 2.pdf

carter_wdo_manual_39_later 2.pdf