|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Home away from home

|

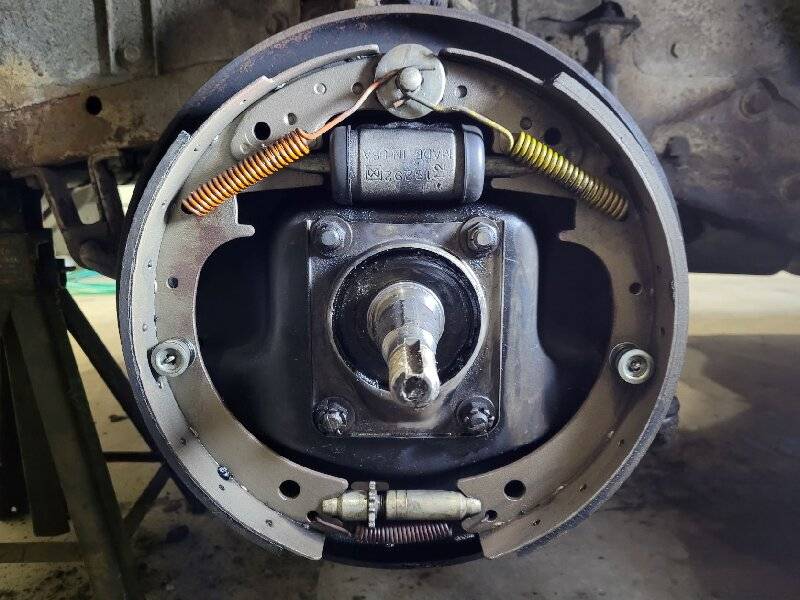

Master cylinder - Kanter or Max Merritt

Wheel cylinder - Just get new ones. They are readily available from NAPA. Front right: Wagner F18291 Front left: Wagner F18290 Rear right: Wagner F18985 Rear left: Wagner F18984 Brake hoses - Wagner UP 11146 from NAPA Radiator hoses - available from NAPA Upper - 7694. It will be long. Cut it to length and use the excess to replace the short hose on the transmission cooler. Lower (for Ultramatics) - 7197 Fan belts - available from NAPA Generator - 7410 Power steering - 7455 Spark plug wires - Any of the vendors...Kanter, Max Merritt, etc. Dwight has some nice ones: https://www.packardparts.org/products/parts/ Shocks - NAPA or Rock Auto Front - Monroe 5751 Rear - Monroe 31125 Carb rebuild - Any of the Packard vendors, Daytona, or Mike's Carbs Fuel pump - Any of the Packard vendors, or Then and Now Automotive. Easiest is to send your pump into Kanter as a core and have them send you a rebuilt one. Nearly all of these parts came from the Parts Cross-Reference here on this site. It can be tough to sort through, but the information is there. I used all these parts on my own car. -Kevin

Posted on: 2023/3/20 17:13

|

|||

|

||||

|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Posted on: 2023/3/22 0:22

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Home away from home

|

I don't know if there is a cross-reference for the pinion seal, but it is available pretty quickly from Max or Kanter. If you have an Ultramatic, the rear U-joint is a rather tricky "Detroit" style, there are the U-Clips available from the major Packard vendors and also some of the Packard clubs.

Whichever u-joint design you have, You have to be very careful to make sure you keep the same # of turns for the pinion nut before and after, because of the crush sleeve design, there are threads here on how to do that.

Posted on: 2023/3/27 16:35

|

|||

|

||||

|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thank you! I'll be sure to do a little reading before I tear into that project.

Posted on: 2023/3/27 16:40

|

|||

|

||||

|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Home away from home

|

If they've been sitting more than a few years it's best to rebuild the cylinders and replace the hoses.

Posted on: 2023/3/27 21:04

|

|||

|

||||

|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Home away from home

|

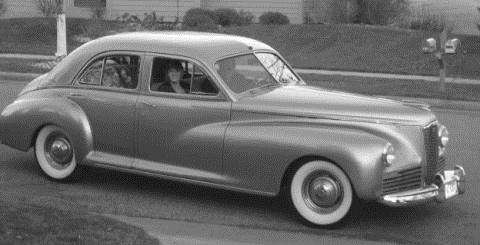

53 Cavalier

It sounds like you might be diving into several maintenance tasks on the car’s ‘rear-end’. I would advise that you DO NOT tackle the pinion seal job with the axles removed. If the axles are removed and you rotate the pinion gear then the ring gear, side axle gears, differential (spider) gears, and thrust block will also rotate, and that rotation may (emphasis on vague) ‘flip’ the thrust block and defeat the ‘floating’ feature that is required. The safe play is to change the pinion seal with the axles and brake backing plates installed. The rest of the brake hardware such as drums, shoes, cylinders, springs, etc. may be either installed or removed during the pinion seal replacement, but you will gain additional confidence that the pinion nut has been reinstalled correctly if the brakes are operational. The caution on this subject is based on the inability to tell whether the thrust block is correctly positioned until the point when the bearing clearance is being checked. Packard shop manuals have the same type of precautionary guidance when installing the ‘third member’. That guidance suggests the use of axle bearing grease to ‘glue’ the thrust block in the correct position prior to installing the differential assembly. The best in car check requires two people, both pushing their axle toward the center of the car and confirming some amount of axle motion occurs during this ‘push of war’. The thrust block translation is easily detected then the axles are cycled back and forth. When forum contributor qbert was working on something similar I provided my thoughts on this subject here: Re: 1953 Clipper Ultramatic pinion nut size [Post-War (1946-54)] - Packard Motor Car Information (packardinfo.com) dp

Posted on: 2023/3/28 14:09

|

|||

|

||||

|

Re: Resting to running!

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for the tip! When I do the pinion seal, I'll ONLY do the pinion seal.

Posted on: 2023/3/28 14:15

|

|||

|

||||

53 Cavalier for including your

53 Cavalier for including your

20230326_165902 (1).jpg (226.73 KB)

20230326_165902 (1).jpg (226.73 KB)