|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Quote:

I thought all Packard window lift were hydraulic?? Only through 1954. For 1955-56, Packard used electric motors supplied by Delco. The round motor design used on 54-55-56 Cadillac, Buick, Olds, and Pontiac (also Delco unit) looks quite similar, but clearly won't bolt up, directly, to our Packards. A GM vendor in the hobby offers a "reproduction" with rectangular motor, which retrofits back to 1955, but same problem with bolt-up: http://www.opgi.com/p/body-moldings-trim/24321/209/CH28542.html I suspect some sort of adapter (pigtail) would also be required to plug in place of the older, two-wire, round motor, GM models; that much might be compatible with the harness in our Packards, since they were supplied by GM-PED.

Posted on: 2012/7/31 9:14

|

|||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

That would be a big help if you might know of something similar size and attachment that could work. Mounting would be one issue since each position is slightly different and the pinion/rack mesh is involved but am sure adapter plates could be made. If the Jag motor can be made to fit, maybe others too -- but am curious how they handled it since there is not much room to play. Maybe a complete new regulator assy is involved. Hope those install notes can be found.

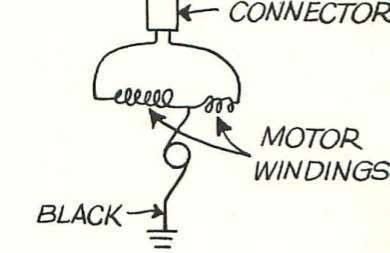

55-56 used a Delco having Packards typical reversing method of two separate counterwound field coils. Power was applied to one or the other coils to reverse direction. If you can think of anything that might have used similar electrics that would be a start. Most modern motors have either separate field and armature wires brought out to be connected by switch or relay in various combinations or get fancy like Peter Packard just described.

Posted on: 2012/7/31 9:40

|

|||

|

Howard

|

||||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Home away from home

|

Pinion and mounting are the 2 difficult parts as you know-and the pinion being the more difficult. I cannot tell much about the pinion from pictures. Modern windowlift and for that matter all auto electric motors are permanent magnet-no field coils. Reversing is achieved by reversing polarity on the armature which is easy to achieve-the controls may not look like the orginal? I have assumed Packard used an arm/sector system? GM in later years used a tape drive

Posted on: 2012/7/31 10:40

|

|||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I've never needed a PW motor, but as folks have been replacing them I'm hoping they've not discarded the failed units as at some point, given enough cores, some can be returned to service and thus discarded cores do have some value, perhaps more so in the future. Fields and armatures can be rewound and other repairs may be possible.

Posted on: 2012/7/31 11:02

|

|||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Not sure how many motors fail from electrical issues or if it's because the worm section twists off the end of the armature shaft or the mating section on the pinion side strips. There have been pictures of both failures here and previously on AACA. With Packards leverage requirements, there is a tremendous amount of force needed from those tiny pieces of metal.

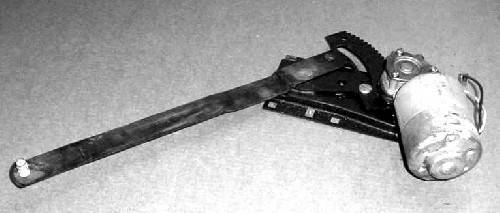

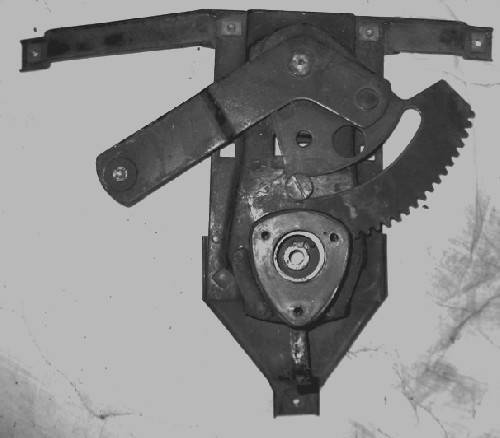

Packard did use lever arrangements in their regulators. A different one for front and rear sedans and another set for hardtops, and of course mirrored assys for right and left sides. Here are a couple.

Posted on: 2012/7/31 11:11

|

|||

|

Howard

|

||||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

What the pictures in this thread haven't yet shown is that the worm screw of the Delco power window motor armature turns a large-diameter, fine-tooth gear that directly turns a small-diameter, large-tooth, pinion gear, to provide some level of torque multiplication. I'm not able to tell whether that's sufficient, though.

However, since the same motor (and gear and pinion ratio) was used front and rear (on same side) regardless of whether it was two-door or four-door body or for door or quarter window of the 55/56 cars, I'd like to think that Packard engineers would have tested for the largest demand. Perhaps that's just wishful thinking on my part. In a past thread, Randy Berger mentioned the lack of sufficient support for the armature - that a bushing could be retro'd. I also wonder how much effect that tired, old, dirty, dried-up grease on the regulator and any worn-out window run channel or lining might have. My dad always cautioned me to lube the sector gear and pinion when the door trim was off - regardless of brand and even on vehicles with manual windows.

Posted on: 2012/7/31 11:41

|

|||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Bob Aller used to turn brass bearings to support the middle of the armature shaft. There is a recess in the casting to hold such a bushing and that would support the shaft and relieve the load overall. Cleaning out the old grease completely and relubing the gears would do much to increase the life of those motors.

Posted on: 2012/7/31 12:18

|

|||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Unfortunately while the bushing might be a good preventive, unless a vendor installs them doing an exchange rebuild am more inclined to believe few will take advantage. Due to the difficulty of access for that kind of work, doubt many owners will be proactive. Realistically, I expect the failed motors are going to be the norm.

Doubt there is going to be enough demand to have new armature shafts or pinion gears made for those that do fail unless they also fit a GM product. Barring the miracle of someone deciding to reproduce the motors or pieces, finding something that will replace what is going to become a more expensive and hard to find item would be the way I would like to see things go. Mechanical will be the issue. Electrical will most likely be easily solved with a couple of relays worked by our original switches.

Posted on: 2012/7/31 12:37

|

|||

|

Howard

|

||||

|

||||

|

Re: Umpteenth power window motor failure

|

||||

|---|---|---|---|---|

|

Home away from home

|

Wasn't there a Studebaker trade letter on using a different kind of motor for the 55-56 cars?

Posted on: 2012/7/31 13:50

|

|||

|

||||

(22.80 KB)

(22.80 KB)