|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Home away from home

|

The largest hole is for the ignition cable. The other holes it really doesn't matter, but if one of the other wires is bigger than the rest, put that through the second largest hole. Slicing would make installation easier, but that's up to you.

Posted on: 2011/3/22 14:00

|

|||

|

West Peterson

1930 Packard Speedster Eight boattail (SOLD) 1940 Packard 1808 w/Factory Air (SOLD) 1947 Chrysler Town and Country sedan 1970 Camaro RS 1936 Cord phaeton packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=4307&forum=10 aaca.org/ |

||||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Home away from home

|

I beg to differ with West's proposal; I think the largest is for the wire harness itself, the second largest for the jacketed ignition cable West refers to. The remaining are choices depending on whether there is an Overdrive Lockout cable to consider. The oil pressure and water temp lines are small. I placed the oil line to the far passenger side since it is on the passenger side of the engine and the water next to. This seemed to create the fewest crossings of wires and lines for an uncluttered appearance. Regarding the installation, yes, you'll need to make a radial from each hole toward the outer perimeter of the grommet (unless you wish to undo lines and push them through, but this is even impossible with the water line). In case you need to add holes, a steel hole punch will do the trick, but you must be careful as rubber is not the easiest thing to punch cleanly.

Good Luck, Pat

Posted on: 2011/3/23 7:41

|

|||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Home away from home

|

See Post #9.

Posted on: 2011/3/23 8:28

|

|||

|

West Peterson

1930 Packard Speedster Eight boattail (SOLD) 1940 Packard 1808 w/Factory Air (SOLD) 1947 Chrysler Town and Country sedan 1970 Camaro RS 1936 Cord phaeton packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=4307&forum=10 aaca.org/ |

||||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

One other way to make very clean holes in rubber that thick is to use a piece of thin wall brass tubing in appropriate size in a drill press or drill or even a lathe.

Bevel one end with a reamer, grinder or sanding belt so it has a reasonably sharp chamfer all around the diameter. Mount the straight end in the chuck. Place a scrap of wood under the rubber and drill away using slow speed. I use a foot pedal on my drill press for ease and can just hold the rubber but clamps can be figured out if wanted and don't distort the rubber. With slow speed and a little water or other lube if needed the tubing will neatly cut a hole. After one hole is made, remove the tubing and push out the scrap piece from inside before making another. I have done this with rubber bottle stoppers an inch or so thick many times. Can go to a half inch diameter or the max size of your drill chuck. Larger if you want to get fancy and figure out how to solder or connect different size tubes together so one end fits the chuck.

Posted on: 2011/3/23 9:42

|

|||

|

Howard

|

||||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

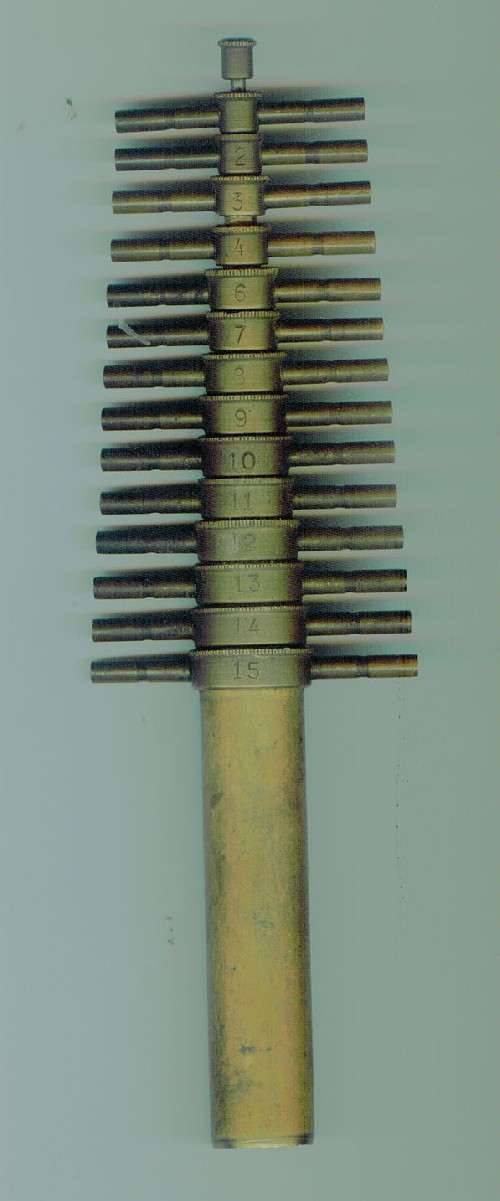

A staple of nearly every working bench chemist in the 60s-80s was a set of brass cork borers with ends sharpened for cutting. These were used for boring various diameter holes in corks, rubber or otherwise, for thermometers and various other entrances/exits of fluids/gases.

I don't suppose these are still available "new" from laboratory supply houses like Fisher Scientific (are they even still in business?) but you might find a set somewhere. They've been nearly indispensable to me over the years for cutting holes in gaskets. Smallest is about 1/16th diameter, largest is 15/16th inch. If you can find a set, you'll have a great addition to your tool chest. EDIT - just checked - yes, Fisher Scientific is still around and the cork borer set is still available from the catalog. Bad news is the price, $144.72. Their catalog says the manufacturer is Humboldt Manufacturing.

Posted on: 2011/3/23 10:37

|

|||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks for all of the advice guys. I certainly appreciate it!

Posted on: 2011/3/23 10:50

|

|||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Webmaster

|

I just used a drill bit to drill the needed holes in my new grommet. Worked just fine. Slitting the grommet to pass through the main harness, and the speedo cable was required, but once the retainer is affixed, it keeps everything sealed nice and tight.

Posted on: 2011/3/23 13:09

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Home away from home

|

I'm going to back pedal a bit here, and claim I was correct in my first response.

The actual wiring harness has to go through a much larger hole, and that you have to drill yourself. I suspect the grommets do not come pre-drilled for the harness because depending on your model and accessories, your harness size could vary considerably. Attached is a picture of mine, and it is clear that my harness is going through, 1. a bigger hole, and 2. a hole that wasn't there when I got it. Attach file:  (38.14 KB) (38.14 KB)

Posted on: 2011/3/23 15:27

|

|||

|

West Peterson

1930 Packard Speedster Eight boattail (SOLD) 1940 Packard 1808 w/Factory Air (SOLD) 1947 Chrysler Town and Country sedan 1970 Camaro RS 1936 Cord phaeton packardinfo.com/xoops/html/modules/newbb/viewtopic.php?topic_id=4307&forum=10 aaca.org/ |

||||

|

||||

|

Re: 1939 120 firewall grommet

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks West. This really helps.

Beautiful engine! You probably know Jim Hollingsworth in Dallas. He has a great collection of 1940 models and has at least one with factory air.

Posted on: 2011/3/23 21:47

|

|||

|

||||