|

tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

who can tell me that? tightening torque head screws 1937 8 cylinder 120 cast iron head.

Greetings Mike

Posted on: 2023/2/26 4:20

|

|||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Webmaster

|

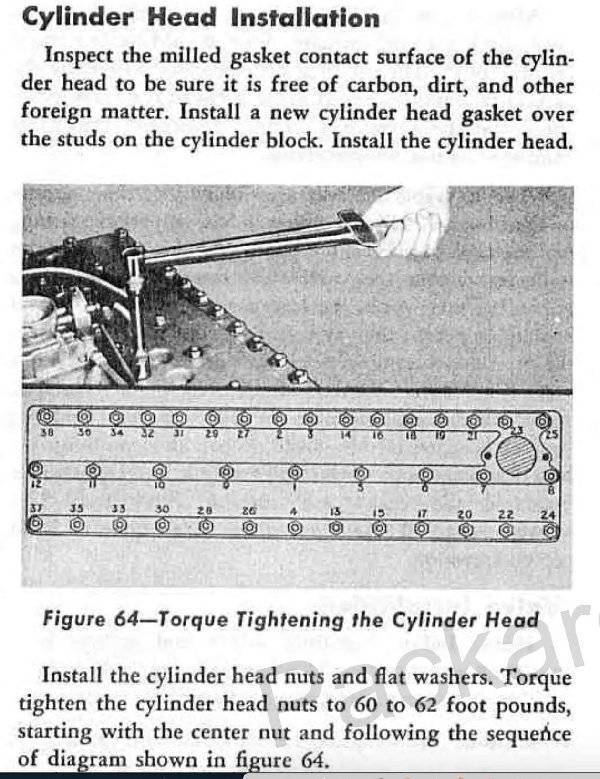

It should be covered in the service manual, here is a snippet.

Attach file:  209_58e16e18c1e53.jpg (87.46 KB) 209_58e16e18c1e53.jpg (87.46 KB)

Posted on: 2023/2/26 8:52

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

thank you you are great.

I have a seal with aluminum frames, can make. that should work better. Greetings and thanks Mike

Posted on: 2023/2/26 11:00

|

|||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Home away from home

|

Quote:

Bob, there has been some chatter on this site about not using distilled water. Not a chemist, but I believe the distilled water will leach certain metals and cause serious damage. Maybe de-ionized water would be a better choice? But, if the water is there only for a short period of time, ordinary tap water should suffice.

Posted on: 2023/2/26 13:48

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Home away from home

|

Sounds good, just wanted to keep the ethyl glycol out of any areas it could stick up the works.

Here is what I have found to back up the claim of not using distilled water: QUOTE "During the distillation process, water is vaporized into its gaseous phase, so all its impurities are left behind. These impurities include a number of minerals, including “calcium” and “magnesium,” the two components of water “hardness.” The water is then condensed back into its liquid phase, so the resulting liquid is pure water – in fact, some of the purest water on earth. But the problem is that when water is distilled, or “stripped,” of its minerals and impurities, the resulting solution is composed of chemically imbalanced “ions.” This leaves distilled water “ionically hungry,” so it will actually strip electrons from the metals in a cooling system as it attempts to chemically re-balance itself. As it chemically removes electrons from the metals of cooling system components, distilled water eventually does extreme damage that could lead to cooling system failure. So what’s the answer? Softened water. During the water softening process, the same impurities and minerals are removed from water as during the distillation process – but with one very important distinction. Rather than STRIPPING the impurities from water, softening EXCHANGES the impurities with a sodium ion. The resulting solution is chemically and ionically balanced, making softened water very stable, very pure, and non-threatening to cooling system metals." END QUOTE I am truly sorry if my ignorance caused any harm. But I did learn something important today! Bob J.

Posted on: 2023/2/26 14:53

|

|||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Home away from home

|

Bob, sharing your research on distilled and de-ionized water was most informative. We all learned something today. Thank you.

Posted on: 2023/2/27 12:05

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Home away from home

|

As always, to achieve the correct torque you need to ensure that threads (on the bolt & in the head) are clean and rust free. You can use a die or tap to clean them up if you need to. A drop or two of oil doesn't hurt either.

Posted on: 2023/2/27 16:09

|

|||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

No oil on the threads when tightening to spec, just clean and dry.

Posted on: 2023/2/27 18:14

|

|||

|

||||

|

Re: tightening torque head screws/1937er

|

||||

|---|---|---|---|---|

|

Home away from home

|

Good advice from all, and imagine being in Germany, you require antifreeze. But never use distilled water, which is ion hungry, leaching minerals; lead, tin, solder among them, from your cooling system. Mercedes issued an adviso about this back in 1989.

Reverse osmosis water the way to go. See the tech link on www.no-rosion.com If you want to split micro hairs, Red Line Water Wetter incrementally better for systems with aluminum, No-Rosion for all iron systems.

Posted on: 2023/2/27 19:11

|

|||

|

||||

Packard Head Torque.pdf

Packard Head Torque.pdf