|

Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

Good afternoon Gents,

I have just finished installing new brake shoes, wheel cylinders and brake lines on the rear of my '39 Six. It all went well and without major issue. I did find the repro shoes were a little 'fat' where the adjuster and cylinder pin notches are to fit over them, but a careful, quick grind brought them down to spec. My question is: in putting the drums back on, is there a torque spec for the 1 1/2" nut on the axle?? I tightened them as much as I could, holding the wheel from turning, and then placed a bar between the locator pin on the drum and the axles flange, with one end of the bar on the floor to keep the wheel from turning and then took them to the 'next hole' on the castellated nut. Could this be too tight?? Any guidance or help much appreciated. Chris.

Posted on: 2022/6/26 15:53

|

|||

|

'If you think you can, or you think you can't - you're right!' Henry Ford.

1939 Packard Six, Model 1700 |

||||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Howard,

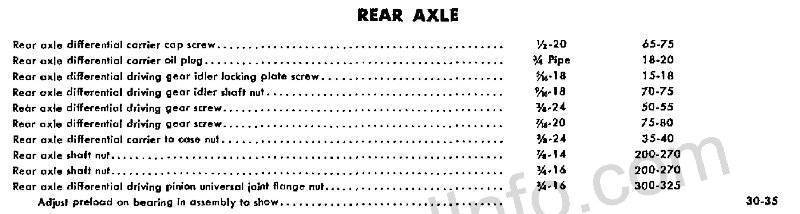

Wow, I sure don't have to worry about them being too tight!!! Am I reading that correctly at 200 - 270 ft. lbs.?!?!? I've got a 3/4" torque wrench and the correct 1 1/2" socket, but that seems like a lot of umph! Chris.

Posted on: 2022/6/26 17:25

|

|||

|

'If you think you can, or you think you can't - you're right!' Henry Ford.

1939 Packard Six, Model 1700 |

||||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

I concur with Howard on this.

In general, there are standard torque charts that you can reference for this. The main difficulty can be determining the grade of bolt, as I believe SAE markings were introduced around 1940; however, if you are using new hardware this issue can be mostly avoided. Generally for steel fasteners that either use standard size nuts, or the bolt screws down its own width or more, as long as both fasteners are rated the same, you can use the standard torque value (assuming that such force will not damage the part you are actually attaching)!

If any of those are not the case, you'll need less torque.

In general, I would reference the postwar service manuals for torque. Easier said than done, but double check as you tighten that it feels about right. Some of the torque values are SAE 5 and some are SAE 8 so I don't doubt that they may have changed 5 for 8 or vice versa over the decades, for the same function.

Of course, given that torque specs were not provided, probably 95% of the hardware is not torque critical anyway

Posted on: 2022/6/26 17:39

|

|||

|

1955 400 | Registry | Project Blog

1955 Clipper Deluxe | Registry | Project Blog 1955 Clipper Super Panama | Registry Email (Parts/service inquiries only, please. Post all questions on the forum.) service@ultramatic.info |

||||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

Chris, as others have said, prior to the early ‘50s the torque specification for the rear axle nut was ‘tighten securely’ . . . while the later guidance was 200 – 270 ftlbs for both the 3/4 inch and 7/8 inch thread geometries. I checked the recommend torque for a 3/4 inch fine thread bolt and found, 223 ftlbs for Grade 5, and 315 ftlbs for Grade 8, so the Packard torque recommendation is not out of line . . . given that the OEM was not constrained to just two particular heat treatments.

The plot thickens . . . most of us subscribe to the notion of a completely dry taper, but don’t mention thread lubricant, or the contact surface between the nut and washer. During production I believe the assembly was dry in all locations, but all surfaces, especially the surface between the nut and washer were ‘new’, that is free of any gouging from previous use. I renewed the washers with Grade 8 hardware, and ‘dressed’ the nut face with an oil stone before the first attempt to have a castellation align with the torque ‘in range’ I was lucky that I could install the cotter pin with the torque in range. After about 100-200 miles I re-checked and found that the torque was below the minimum, and the nut needed a bit more ‘dressing’ to achieve the torque ‘in-range’ and pin aligned. A loss of torque on a tapered hub is not uncommon during initial run-in. Tightening of the axle nuts can be done with the weight of the car on the wheels . . . emergency brake off. I prefer to back-off the service brake adjustment a bit, and then do the final adjustment of the rear brake after the axle nuts have been dealt with. A 7 year old grandchild on the end of a four foot bar should be close to the correct torque.

Posted on: 2022/6/26 18:01

|

|||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks David, I'll go through the assortment and I'm sure I can find a 7 year old grandchild in the mix somewhere! LOL My Thinking is, that if a castellated nut is the designed method of holding the nut from loosening too much, then the torque spec can't be that critical as the 'from-to' on one castellation is quite liberal. I will follow your advice and 'chase them' after a few miles to see if they have lost any tension.

Now comes the next query: is there a preferred grade of brake fluid for these systems? What I have been putting in the car I believe was DOT 3. I recall someone mentioning DOT5 in another post on a separate brake discussion, but can't recall the ultimate correct answer. Chris.

Posted on: 2022/6/29 20:35

|

|||

|

'If you think you can, or you think you can't - you're right!' Henry Ford.

1939 Packard Six, Model 1700 |

||||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

There is no "ultimate correct answer", both types (conventional fluids, DOT 3 and DOT 4) and silicone (DOT 5) have their advantages and disadvantages. And conventional (OEM type) and silicone are mutually incompatible so changeover requires a thorough purging and flushing, and many will also recommend renewing all rubber parts as part of the conversion.

Posted on: 2022/6/29 21:40

|

|||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

On my 31, I put the tire on it, chocked it with a cinderblock, then torqued the nut to 200 lbs, then rotated to the next passage on the castle nut. Need to check it again soon.

Posted on: 2022/6/30 5:56

|

|||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Dave and Greenfield for the info. Dave, you cleared up my confusion on brake fluid; I didn't realize Dot 5 was silicone. What I have on hand in good quantity (and have been using) is DOT 3 so will just continue with that and see if I can get them bled to a nice, hard pedal.

And Greenfield, I'll definitely try your chocked wheel method for torqueing the axle nuts, sounds good to me. Thanks; Chris.

Posted on: 2022/7/1 17:41

|

|||

|

'If you think you can, or you think you can't - you're right!' Henry Ford.

1939 Packard Six, Model 1700 |

||||

|

||||

|

Re: Torque spec????

|

||||

|---|---|---|---|---|

|

Home away from home

|

I bow to OwenDyneto's deep knowledge of Packardania, but there are no disadvantages to DOT 5 silicone brake fluid, which, regardless of brand, is made by Dow Corning. The USPS fleet uses nothing but, as has the military in the arctic for decades.

Simple. Flush your brake system thoroughly with alcohol first. DOT 5 is non-hydroscopic; it does not absorb moisture from the ambient air as do glycol-based DOT 3 and 4 (Girling). DOT 5 has a higher boiling point than either. Master and wheel cylinders corrode because of moisture. Using DOT 5 as directed prevents that. Several lifelong Packard, Cord and other owners have had the same batch in their cars since the 1980s and it still looks new.

Posted on: 2022/7/2 0:28

|

|||

|

||||

torque.jpg (114.30 KB)

torque.jpg (114.30 KB)