|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Home away from home

|

Also, what is the torque for the spark plugs? 53 Clipper Deluxe Is it really important? I don't think this guy knows it. Never again.

Posted on: 2017/4/14 23:21

|

|||

|

1953 Packard Clipper Deluxe

She starts on the first crank in the morning and purrs like a kitten all day.

|

||||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Home away from home

|

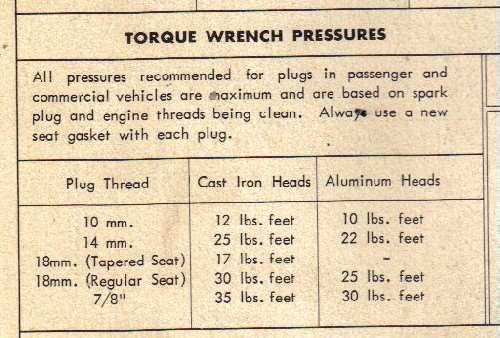

Sparkplug gap of .025 is what you want. Plugs should be tightened to 25-35 ft-lbs.

Is it important? Yes, for a couple of reasons: first is that you don't want them to work loose and attempt to launch through the hood of the car. Second is that the plugs must be firmly seated so they can transfer heat out into the cylinder head. By their shape, they are greatly heated by the combustion gasses. If not screwed in nice and tight they get much hotter than designed which can cause them to misfire under load. Further, if they are that hot, they can cause pre-ignition--pinging or knocking that is very destructive, not to mention annoying. When I was younger and dumber I used the technique I learned as a farmboy which was to put the plugs in hardly more than finger tight as we were forever changing plugs on one of the tractors. My 60 Lark would knock like crazy on hard pulls. Since I started using a torque wrench to reef them down I have never hear another ping from that car. Caveat to 54 Senior car owners or those with 10 mm plugs--look up the correct torque for those as I don't have it at my finger tips this morning.

Posted on: 2017/4/15 6:03

|

|||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

AC recommendations from their 1962 catalog:

And yes, Packard did use both 7/8" and 18mm in years prior to 1932.

Posted on: 2017/4/15 8:00

|

|||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

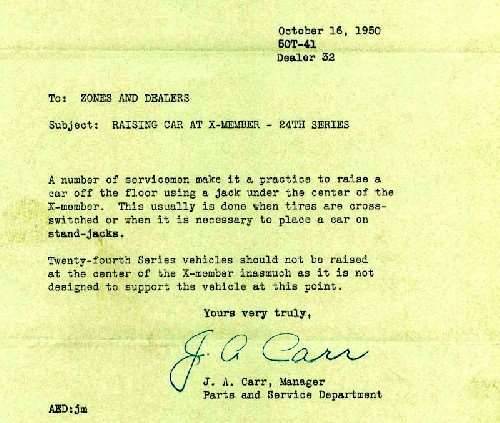

Quote:

Also, the mechanic who checked the brakes jacked it up in the center of the car and left it on the jack for 4 1/2 days. WTF! I told him to put the tire back on and lower it, that I thought a 64 yr old car shouldn't be left on a jack. He got stupid. Please tell me your thoughts. Your instincts were 100% correct in getting upset with the way the car was supported. It is not a good idea to lift and support your car by the center X for 4 1/2 minutes let alone 4 1/2 days. It was apparently common practice with pre 51 Packard models to raise cars by the center X but when the 51 models came along with their different frames the practice was definitely not approved by Packard. They went so far as to issue a service bulletin advising against it. Your 53 has virtually the same frame as the 51 so would also be a model in the do not do it list.

Posted on: 2017/4/15 9:50

|

|||

|

Howard

|

||||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Webmaster

|

On my '54. I lift the rear with a floor jack under the diff, and then support it with two jack stands under the rear axle tubes as far outboard as possible. In the front, I lift under that wide engine crossmember, and place the jack stands under the frame just forward of the firewall.

I've left my car suspended in this manner for months at a time when I was working on it, in it, and below it.

Posted on: 2017/4/17 8:46

|

|||

|

-BigKev

1954 Packard Clipper Deluxe Touring Sedan -> Registry | Project Blog 1937 Packard 115-C Convertible Coupe -> Registry | Project Blog |

||||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Home away from home

|

I tend to locate the jacks on the frame itself, with the lift pad as close to the wheel as practicable, but ultimately the jack location is determined by the frame strength . . . in short, put the jack were the frame looks the strongest. Given that cars of this era were supplied with bumper jacks I place the jack stands at the bumper brackets, but close to the frame horns. If possible I leave the hydraulic jacks in place, so unless I have to 'crawl under' there is a jack stand and jack at each corner. I know I should never trust a hydraulic jack alone, but in this case the jack stand is the primary means of support, with the hydraulic unit in a supporting role (pun intended). The jack stand and the hydraulic jack are sharing the load, but I can't tell by what ratio. The only difference between this arrangement and the one BigKev uses is the location of the rear tires. My scheme has them 'dangling, while BigKev's has the rear wheels up into the tubs. In both cases the front wheels are 'dangling'.

I'm currently working on a set of wooden blocks ( laminations of ? plywood ) that are 1'X2' by 3" thick. One sheet of plywood is enough material to lift all four wheels of the car 3 inches (nominal ). I made enough of these blocks to lift the car 1 foot. That would be 4 sheets of plywood, 16 blocks in total - which cost approximately $130. Four of the blocks will have integral stops so the car can't roll. I bought the plywood at my local Home Depot and they cut the sheet goods into sizes that were manageable. I looked at framing lumber ( 2 X 12 ), but that material was cupped to the point that it was unusable. Framing lumber and plywood ended-up about the same cost, while engineered beams were quite cost prohibitive. In the near future I will have the car sitting on its tires when I'm doing the routine under the car maintenance. Clearly not suitable for wheel or brake work, but OK for the normal 'get out and get under'. I seem to fear gravity a lot more now than I did when I was a young man, and there doesn't seem to be a cure coming anytime soon.

Posted on: 2017/4/17 17:29

|

|||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Just can't stay away

|

Ladys and Gentlemen... of a certain age.. don?t try crawling under your cars any longer! in 1967 they invented some rather usefull tool for you: the lift with 2 stands! The frame of the Packard is wide enough to find solid hold on it but you can feel the doors do slam a bit harder. For that, if not all 4 wheels have to come of (or an offroad-car with a very short frame shall be lifted), I prefer the lift with 4 stands that makes maintainance so easy with a small jack-bridge attached (see in the middle under the front of red G). Those lifts are no longer very expensive ... they cost much less than a broken spine! and if your garage is high enough, you can park another car under the lifted one.

Posted on: 2017/4/18 5:28

|

|||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Home away from home

|

"..... but ultimately the jack location is determined by the frame strength . . . in short, put the jack were the frame looks the strongest. Given that cars of this era were supplied with bumper jacks I place the jack stands at the bumper brackets, but close to the frame horns."

The frame horns where the bumper brackets are are the weakest part of the frame and the cross section is the smallest. They do not have to support the engine or weight of the car except the rearmost body mounts. Frames are engineered so that the wheels are intended to support the car so the best way to support a car is nearest to the "axles". In the front that would be either under the A frames or at the center point of the frame between the wheels. In the rear it would be under the rear axle housing or axle tubes or on the frame forward of the rear spring front mount. Supporting it by the ends of the frame will cause it to sag and bind the doors especially on 2 dr hardtops and convertibles. When working on the car it should be supported by jack stands only, no portion of the weight should be supported by a hydraulic or other jack.

Posted on: 2017/4/18 7:40

|

|||

|

||||

|

Re: spark plug gap for 53 Clipper and jack position

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

Unless I'm working on some aspect of the suspension that requires the car to be supported by the frame, I always support under the suspension - generally under the rear axle tubes at the outer extremities in the rear (or under the spring perch if I need more elevation), and under the front A-frames (independent suspension) or under the front spring perches on the axle (beam axle cars). Jackstands always, never just a jack. On those occasions where I must support by the frame, always inboard of the axles, never at the extremities of the frame.

Posted on: 2017/4/18 8:55

|

|||

|

||||

(71.06 KB)

(71.06 KB)