|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

I think it is a good plan and a thin plywood support would work or maybe hardboard (masonite) might work better because it has one face a bit flatter and smoother than plywood surfaces. Not sure I would use contact cement though unless you find one with a very low tack. Maybe there is something in the art world used for holding photos to mat material that has a light grip. I think Krylon makes a spray adhesive that is light and reusable for that purpose. If too tight a grip you might have trouble removing the adhesive from the finished shim or shim from the board without bending it -- although with the placement on the axle am not sure a small bend would be too much a worry as long as there is no sharp crease or wrinkle. If no light duty spray-on stuff is available where you are maybe some shelf contact paper would work as a light adhesive to hold the shim material. Glue the decorative side to the board and then place the shim material on the contact adhesive surface..

Don't know how many shims you are making but if more than one think I would fasten a piece of shim stock to a panel, then face the smooth sides of two panels together and securely fasten the pair to make a sandwich with the shim stock in the middle to do the cutting. That way it is well supported from both sides and you would have a pair of identical pieces. They would be mirrored but I think the axle shims are symmetrical so shouldn't make a difference.

Posted on: 2019/4/14 13:25

|

|||

|

Howard

|

||||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Home away from home

|

I don't think that brass, wood Masonite or any soft material is a good idea due to its ability to crush. The original were steel (probably die-cut) so that would be your best bet.

Posted on: 2019/4/14 13:39

|

|||

|

All generalities are false.

Once I thought I was wrong but I was mistaken. Don Pierson Packard / IMPERIAL page CA DMV Licensed Vehicle VIN Verification 1951 Henney-Packard 3-Door Long Wheelbase Air Force Ambulance The 1951 Henney-Packard is For Sale! 1954 Packard Patrician 1954 Packard Patrician Parts Car 1956 Clipper Custom Sedan |

||||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Home away from home

|

Mark, what are you working on? I have shims coming out of my earballs and could send you several dozen. Besides, every Packard I ever serviced needed shims removed to diminish the axle end play.

Posted on: 2019/4/14 13:49

|

|||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Home away from home

|

Thanks Howard and Ross,

I am working on a 47 custom super that uses shims as shown in photo, lower right. Ross, you are right I need to decrease thickness, but right now I have a single .030 shim that yields and end play of just over .007 - the high end of the recommended range. So, I planned on making several shims and stacking them, shooting for a thickness of .028. Howard, your idea of sandwiching between Masonite is brilliant. Ross, am sending you a PM. Thanks guys.

Posted on: 2019/4/14 14:37

|

|||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Home away from home

|

Do you have any axle shims for a 1951 200? I bought the inner and outer seals and gaskets today. I bought the bearings and cups a couple of days ago. I have assess to a press. I don't have a tool to measure the end play. I have the new wheel and master cylinders and a brake hardware kit.

Posted on: 2019/4/17 15:19

|

|||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

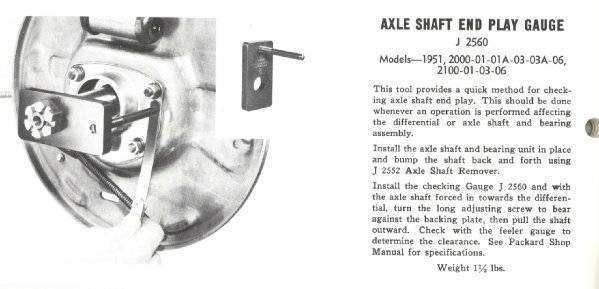

Quote:

I don't have a tool to measure the end play. The tool is very simple and can be made fairly easily. Here is an illustration of the bare tool and with it mounted. Size is not terribly critical but as I recall it is roughly 2 inches wide and 5 inches long. Get a piece of material thick enough that it won't flex. Steel, aluminum or even wood would work. If you use wood it also needs to be thin enough that it can slide on the axle threads and still leave enough room the nut and washer can be threaded on a few turns to hold it tightly. Drill a hole large enough for the threads on the axle and locate it toward one end of the block. Drill another smaller hole toward the other end of the block so a 1/4 or 5/16 length of all thread can be inserted and tightened . Use a nut on both sides of the block to adjust the length of the all thread. Once the block is in position on the axle follow the instructions in the SM to adjust the all thread end to the point touching the backing plate and proceed with the measurement.

Posted on: 2019/4/17 16:02

|

|||

|

Howard

|

||||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Home away from home

|

Now that is a handy bit of information Howard. Thanks

Posted on: 2019/4/17 22:00

|

|||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Forum Ambassador

|

G'day kunzea,

See you've been a member here for some time but first post/s so  And, I invite you to include your '51 200 in the Packard Owner's Registry.

Posted on: 2019/4/18 0:57

|

|||

|

Mal

/o[]o\ ====  Bowral, Southern Highlands of NSW, Australia "Out of chaos comes order" - Nietzsche. 1938 Eight Touring Sedan - SOLD 1941 One-Twenty Club Coupe - SOLD 1948 Super Eight Limo, chassis RHD - SOLD 1950 Eight Touring Sedan - SOLD What's this?  Put your Packard in the Packard Vehicle Registry! Here's how! Any questions - PM or email me at ozstatman@gmail.com |

||||

|

||||

|

Re: axle shim material

|

||||

|---|---|---|---|---|

|

Home away from home

|

Like Howard suggests, easy to make a tool to measure the axle shaft end play. Here is a photo of a JW-Made tool I made to do the job.

Posted on: 2019/4/18 10:45

|

|||

|

We move toward

And make happen What occupies our mind... (W. Scherer) |

||||

|

||||

(242.65 KB)

(242.65 KB)

(112.79 KB)

(112.79 KB)